Much more to choose in local range of SEW-EURODRIVE planetary units

Jonathan McKey, National Sales and Marketing Manager at SEW-EURODRIVE

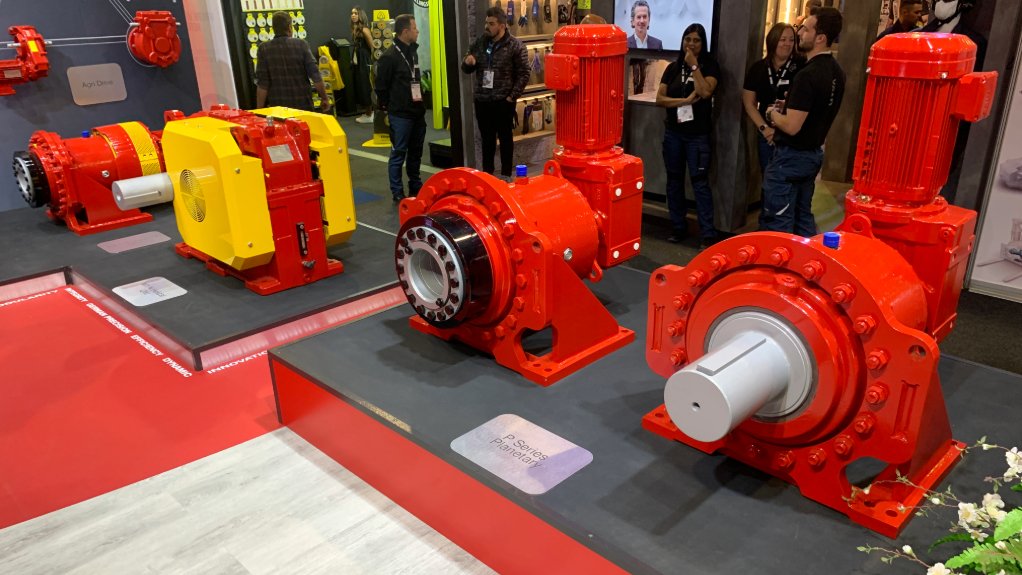

SEW-EURODRIVE's newly launched planetary gearbox solutions are available in South Africa

SEW-EURODRIVE's range of planetary gearbox solutions

This article has been supplied.

As SEW-EURODRIVE in South Africa actively extends its offerings to customers, the SEW PPK and SEW P2.e industrial gearbox ranges are good examples of solutions that are well suited to the local business environment.

“Being part of a well-established global business, we are drawing increasingly from the group’s production plants in various parts of the world,” says Jonathan McKey, National Sales and Marketing Manager at SEW-EURODRIVE. “This approach allows us to select products that have been tried and tested in sectors relevant to our own, and under operating conditions that are closely comparable.”

McKey highlights that this strategy is opening up a much larger range of choices for customers in South Africa and the rest of the continent, as the company ‘closes the loop’ by adding new offerings to complement its successful portfolio. A valuable recent addition has been the SEW PPK planetary gearbox range, originally designed and produced by SEW-EURODRIVE in Brazil – with their world class sugar industry as a key user.

“The depth of research and development capability with the group allowed Brazil to develop the SEW PPK concept, to give their sugar mills access to a low torque solution which complies with SEW-EURODRIVE’s stringent global standards and specifications,” he says. “Later, engineers in Germany additionally developed the SEW P2.e series for larger applications.”

Both the SEW PPK and the SEW P2.e ranges are now available to customers in South Africa and Africa, allowing SEW‑EURODRIVE to further augment its planetary offerings. He reiterates that planetary gear units are particularly valuable for those applications that require a compact solution in conditions where space is constrained, while also demanding high torque and low speed outputs.

“Our SEW PPK range is well suited to southern hemisphere markets, delivering 2 to 18 kNm of torque with a ratio range from 65 to 10,700:1,” he says. “The ratio can be further reduced by the addition of a primary reducer before the planetary head, to reach ratios up to 10,650:1 – for a much lower speed capability.”

Developed as the ‘big brother’ to the SEW PPK options, the SEW P2.e series encompasses higher torque ratings from 2 to 124 kNm with ratios from 15,2:1 to 332:1. McKey explains that the SEW P2.e was developed with all the benefits of the SEW PPK, but with a broader spectrum of diversity in its speed – up to 100 rpm – as well as in ratio and torque. While most planetary gearboxes have a three-stage design, the SEW P2.e can also be supplied in a two-stage model.

“What is exciting for local customers is that we have now brought a complementary range of both the SEW PPK and SEW P2.e to this market – giving a wide selection that will suit many new applications,” he says. “This allows us to compete well with other planetary manufacturers, as we can now offer customers most of the capabilities of other brands – all within our SEW-EURODRIVE stable.”

This means that customers can spend less time searching across different OEMs for a solution that will meet their specific needs, he emphasises. Instead, they are likely to find what they need within the expanded SEW-EURODRIVE brand offering.

“We are the only manufacturer who allows for direct electric motor coupling to a planetary gearbox; this is unique to our SEW P2.e solution,” he points out. “Our units also accommodate radial labyrinth solutions, which many competitors do not. This provides an extra layer of protection for the sealing systems on the output shaft – a valuable feature in corrosive and dusty environments like mining.”

For customers wanting to upgrade from previous P-series models of planetary gearboxes to the new SEW P2.e, SEW-EURODRIVE has been careful to retain the same critical dimensions. Greg Lewis, SEW-EURODRIVE Sales Manager , says this allows customers to migrate seamlessly without altering their existing infrastructure. Lewis points out that the SEW P2.e is one of the only planetaries available with a cooling solution, positioned between the planetary and the motor.

“This gives us thermal ratings that are far superior to competitors,” he says. “By adding a fan on the input side to further cool the gearbox, we can considerably enhance its thermal capabilities.”

Lewis notes that, while the SEW P2.e units have directly mounted motors, the SEW PPK offers different options for coupling existing motors using our adaptors – the AD adaptor with input shaft or the AMS adaptor for the flange mounted motor.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation