New hands-free bit changer for drill rigs

An Automatic Bit Changer (ABC) that is designed to change rotary tricone bits significantly faster than manual exchanges and eliminate human interaction with the drill string, has recently been introduced.

Epiroc’s ABC enables hands-free bit changes on Pit Viper 270 and Pit Viper 290 series drill rigs used in rotary drilling. The ABC allows operators to complete hands-free drill bit changes with the touch of a button and the use of an interactive screen, to make or break joints, select drill bits, and add or remove bits. Drill bit changes can be done from a control room or from inside the cab. The ABC drill bit helps ensure a safer, more efficient way to operate a drill fleet, by improving productivity and reducing exposure to live work environments.

“The early collaboration with customers and cross-functional teams resulted in an auto bit changer that is repeatable, keeps the operator out of the line of fire, and improves machine uptime,” said senior design engineer: surface division Matthew Fosler.

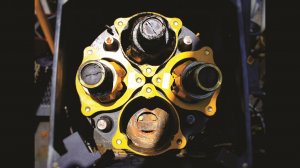

The carousel design of the ABC allows up to four bits to be changed faster and safer than a single manual exchange. The removable bit carousel can store rotary tricone bits in varying sizes and cutting structures, with a total of four on-board bits, aimed at enhancing flexibility and versatility on a drill site. The ABC allows users to safely replace the worn drill bits with a range of bit types and sizes.

Available for new drills and retrofit of existing drills, the ABC is designed to be easy to maintain, and its compact, above deck design also makes it more compact. The above deck design aims to ensure that maintenance procedures are simpler and safer to perform and operator viewing angles are optimised. Retrofits for the working Pit Viper fleet are also available.

Epiroc asserts that customising a Pit Viper 270 or Pit Viper 290 drill rig with the ABC option offers a range of benefits, such as easing operator workload, as well as reducing human error, injuries related to heavy lifting, lost time on manual adjustments, accidents and exposure to dust and noise.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation