SA company supplies urethane product to Moroccan project

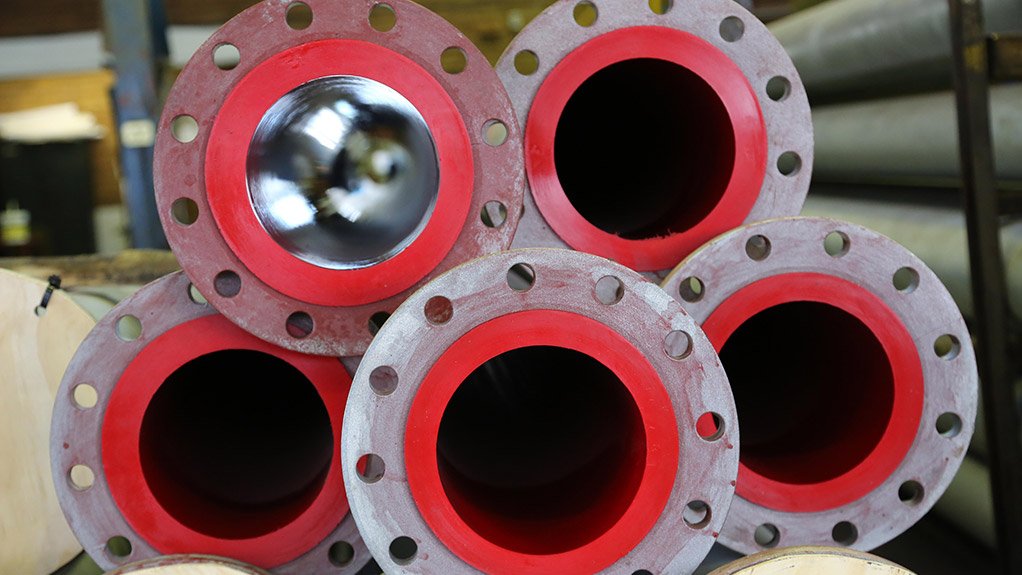

Pipeline service specialists Aptec explains and highlights the details surrounding the Aptec Sure-Liner pipe lining system.

SEAMLESS SYSTEM PROVIDED UMP partnered Aptec to create and bring the Sure-Liner and Redline, HDPE pipe systems and polyurethane internal pipe-lining systems to Africa as an integrated slurry tr

South Africa-based polyurethane manufacturing company Urethane Moulded Products (UMP) successfully completed and supplied polyurethane lining for the Jorf Lasfar slurry pipeline project, in Morocco. The project won best project in the International Projects category at the South African Institution of Civil Engineering 2015 awards, held in October.

UMP was the only company worldwide that could supply the precision urethane- lined, 900-mm-diameter steel pipelines’ special bends and fittings requested by Turkish construction company Tekfen Construction. UMP designed and developed the specialised process equipment, such as ovens and moulds, required to line the 900 mm bends.

UMP director Trevor Carolin tells Engineering News that the actual size of the pipeline bends was a challenge, as it affected the volume of the polyurethane to be injected into the bends, as well as the tools that were required to fit inside the bend.

Fitting the moulds into the bends was a difficult task, as the pipe bend weighed about 9 t; coupled with this, the lining thickness had to be very specific. The tools used to line the pipeline were developed by UMP, as the company had to determine how to manoeuvre the lining in and out of the pipe, before and after it had been moulded.

Further, certain areas of the bends in the pipeline were not completely round, but oval. Subsequently, UMP had to design a mould that was oval in the centre, but could fit through the round hole at the end of the pipe, Carolin explains.

He states that five UMP engineers worked continually on developing the technology for three months and, once that was completed, the company moved into the six-month production period, during which 24 containers were filled with the urethane-lined pipelines and shipped to Morocco.

Carolin notes that UMP’s design and development of the technology used for the pipeline bends was a successful R3.5-million investment, as the technology is being exported to Zambia, Angola, Botswana, Namibia, Australia and even Saudi Arabia.

UMP’s polyurethane lining meets the specialised demand for pipeline applications where there are high abrasion areas and sharp rock particles. For example, UMP provides specialised pipes and fittings for Zambia’s copper, gold, iron-ore, platinum and phosphate mines.

He adds that UMP has promoted the polyurethane as an alternative to the usual rubber-lined bends because polyurethane can extend the life of the bend by up to ten times, with “a component that [lasted] two to three months now lasting close to two years”.

Aptec

UMP partnered with US-based multi- national pipeline service specialist Aptec in November last year to create and bring the Sure-Liner and Redline, high-density polyethylene (HDPE) pipe systems and polyurethane internal pipe-lining systems to Africa as an integrated slurry transport solution.

Carolin explains that the Sure-Liner internal pipe-lining process involves inserting a tight-fitting HDPE plastic-liner pipe inside a steel pipe, thereby taking advantage of the mechanical strength of the steel pipe, combined with the corrosion and abrasion resistance of the plastic liner. The 1 km steel pipe does not require any flanges, which are one of the biggest cost inputs, comprising up to 30% of the cost of a pipeline.

The seamless system is ideally suited to long-distance slurry transport pipelines, especially high-abrasion applications such as backfill, mineral sands, concentrate and tailings lines. UMP says HDPE in straight pipelines and Redline polyurethane in bends and laterals complement each other, owing to their matching internal diameters.

An advantage of the Sure-Liner pipeline is its enhanced security, as the bolts on the flanges are often stolen. Once the pipes start operating, they burst open as a result of the pressure not being contained, creating health and safety risks as well as environmental damage at mine sites.

“Our partnership with Aptec enables us to work together to develop the pipeline technology in Southern Africa. Wherever possible, labour will be sourced locally, while training and supervision are provided by Aptec,” concludes Carolin.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation