SEW-EURODRIVE builds regional strength with Gqeberha expansion

Phillip Steyn, SEW-EURODRIVE Gqeberha Branch Manager

The exterior of SEW-EURODRIVE’s Gqeberha branch showcases the company’s strong regional presence and commitment to serving customers in the Eastern Cape

The interior of SEW-EURODRIVE’s Gqeberha branch workshop reflects a well-equipped facility designed to deliver efficient assembly, maintenance and support services to local industries

SEW-EURODRIVE’s Generation C MOVI-C® electronics range offers advanced automation solutions designed to enhance efficiency, flexibility and connectivity in modern industrial applications

The MOVI-C® digital motor integrates seamlessly with MOVILINK® DDI interfacing, enabling power supply and real-time condition monitoring through a single hybrid cable for streamlined connectivity

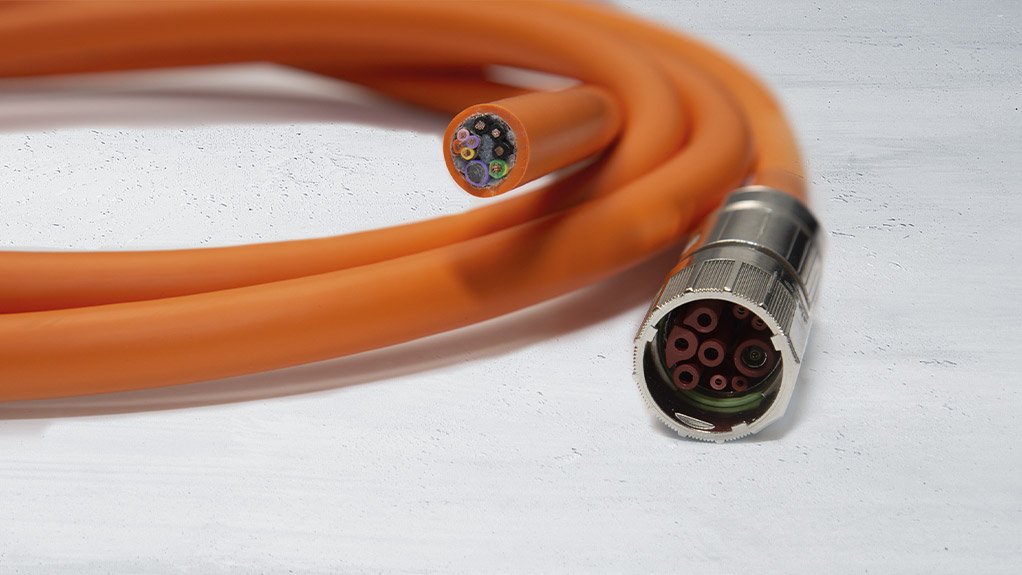

The MOVILINK® DDI hybrid cable from SEW-EURODRIVE combines power and digital data transmission in a single cable, enabling efficient communication and condition monitoring between motor and drive

This article has been supplied.

With the Eastern Cape firmly established as a hub for key industries such as automotive manufacturing, ports, agri-processing and renewable energy, SEW-EURODRIVE is strengthening its presence in the region through an ongoing significant expansion of its facility in Gqeberha. From this strategic base, the company delivers world class drive, automation and motion control solutions tailored to the needs of local industry, backed by responsive service and deep technical expertise.

Phillip Steyn, SEW-EURODRIVE’s Gqeberha Branch Manager, says the investment is a reflection of both the company’s long-term commitment to the Eastern Cape and the growing role the region plays in South Africa’s industrial landscape.

“The Eastern Cape province has always been a strategic priority for us,” says Steyn. “Our ongoing investment here is about more than infrastructure – it is about being closer to our customers, understanding their operations and being in a position to respond swiftly with strategic solutions.”

The new investment in a 2,400m² facility represents a substantial upgrade from the previous 850m² space, significantly increasing local capacity. The expanded operation includes purpose-built assembly stations, dedicated painting and dispatch areas and a comprehensive service centre. Equipped with overhead cranes that can handle drive units of up to 10 tonnes, the facility will also feature a high-pressure cleaning system and advanced electronic testing infrastructure to support local refurbishments and ensure equipment is returned to service in peak condition.

Steyn notes that the expansion is enabling faster turnaround times and enhanced support for customers. “We have moved from being a local service point to a fully-fledged regional hub,” he says. “We’re now able to hold more stock, assemble to order and carry out major repairs – all from Gqeberha.”

Further continued investments planned for 2025 will include a dedicated experience centre, where customers can interact with the latest Generation C mechatronic drive solutions, conduct energy studies and test new programmes in real-world conditions. This is part of SEW-EURODRIVE’s focus on providing intelligent energy-efficient solutions that support industrial performance and sustainability.

The branch also supports major industrial projects across the Eastern Cape including drive systems for fruit processing and packing plants and upgrades at the local Coega IDZ ports. Its engineering team works closely with customers to develop application-specific solutions, supported by a strong aftermarket network and global logistics reach.

“SEW-EURODRIVE’s continued investment in our Gqeberha branch provides a well-resourced facility that allows us to serve customers from a strong local base,” concludes Steyn. “Our focus is on delivering efficiency, flexibility and innovation to power industrial success across the Eastern Cape.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation