South Africa’s green direct reduced iron export potential highlighted as industry mulls decarbonisation options

Swedish Ambassador to South Africa Håkan Juholt

Photo by TIPS

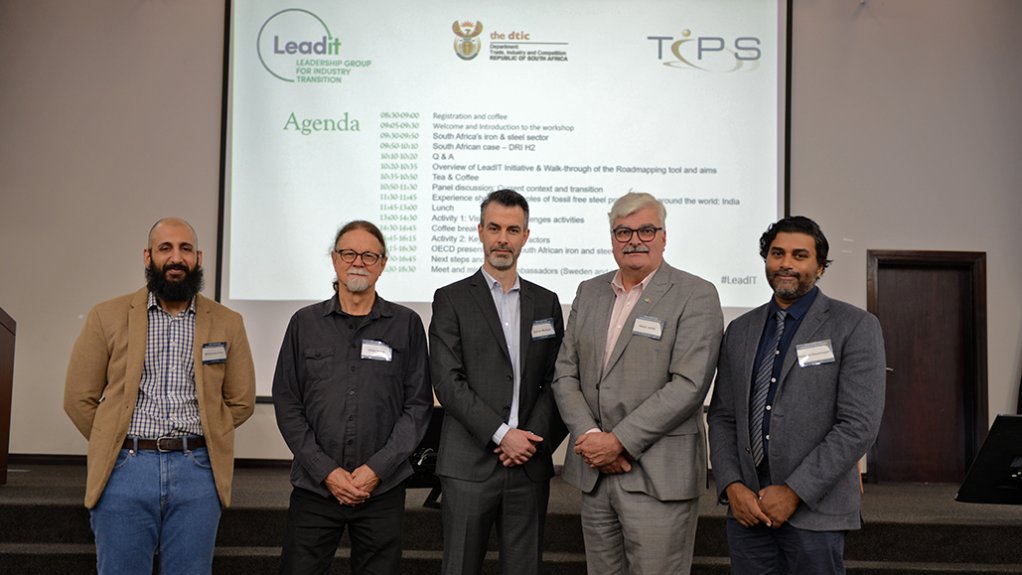

Muhammed Patel, Hilton Trollip, Dr Aaron Maltais, Håkan Juholt and Mahendra Shunmoogam at consultaiton on the decarbonisation of the steel value chain

Photo by TIPS

Government and the steel industry are considering the potential of positioning South Africa as a global exporter of green hydrogen direct reduced iron (GHDRI) as part of a broader discussion to develop a roadmap for the decarbonisation of the iron and steel value chain.

Department of Trade, Industry and Competition primary minerals beneficiation and construction director Mahendra Shunmoogam told stakeholders during a meeting in Sandton that green processing and production are likely to become a significant competitive advantage, especially in the export market.

“The Steel Master Plan proposes that the industry agrees to a target for the industry to reach carbon neutrality by 2050,” Shunmoogam said, noting that South Africa had, thus, joined the Leadership Group for Industry Transition (LeadIT) in 2022 with the objective of partnering with external stakeholders to enable a greening of the sector.

Launched by the governments of Sweden and India in 2019, the LeadIT platform includes countries and companies that are aiming to achieve net-zero carbon emissions from heavy industry by 2050.

Together with Trade and Industrial Policy Strategies (TIPS), the platform is helping to facilitate South Africa’s consultations on the decarbonisation of the country’s steel value chain, with the LeadIT secretariat’s Dr Aaron Maltais reporting that South Africa was the newest country member of the platform, which currently comprised 18 country members and 18 companies.

Swedish Ambassador to South Africa Håkan Juholt said the time for speeches by government officials was over and that it was now crucial for industry stakeholders to collaborate on decarbonisation solutions in sectors such as iron and steel.

He noted that Sweden was itself in the process of transitioning its steel industry, highlighting in particular the progress being made in the military town of Boden in a county that borders Finland and Norway, where a mill is being built with the potential to produce five-million tons yearly of carbon-neutral steel by 2030, using hydrogen technology.

“We are determined [as Sweden] to be first into the new, not last out of the old,” Juholt said, after quoting the late Swedish trade unionist and politician Göran Johansson who once told his union colleagues that he was never afraid of new technology, but deeply afraid of old technology and the impact that holding on to such technology could have on jobs.

University of Cape Town research fellow Hilton Trollip used the engagement to make the case for South Africa playing a central role in the global green steel transition, initially by using green hydrogen to produce GHDRI for export, primarily to Europe.

He argued that South Africa’s combination of potent renewable resources, land and good quality iron-ore positioned it as a potential least-cost supplier of an emerging global commodity, in the form of GHDRI, which could make it possible for the world to meet the Paris Agreement goals.

Without it, as well as other mitigating actions, it would be near impossible to decarbonise a sector that currently made up 8% of thermal emissions.

Trollip noted that several other countries, including Australia, Austria, Belgium, Canada, China, Finland, France, Germany, Norway, Oman, Romania, South Korea, Spain and Sweden had already announced GHDRI projects and that ArcelorMittal South Africa had also indicated its intention to produce the commodity from 2030.

The JSE-listed steel group is considering producing GHDRI using the Midrex plant at the mothballed Saldanha Steel mill, in the Western Cape, using green hydrogen produced by an electrolyser where renewable electricity is deployed to split water into hydrogen and oxygen.

“We think it must be earlier,” Trollip said, arguing that besides supportive resources, South Africa also had the technical and financial know-how to pursue GHDRI projects.

He warned, however, that global decarbonisation at rates consistent with the Paris Agreement goals was unlikely without substantially more global cooperation, including a levelling of the international playing field, whereby mechanisms ought to be found for developed countries to extend support for primary steel manufacturing in developing countries such as South Africa.

TIPS senior researcher Muhammed Patel argued that it was important for the South African steel value chain, which currently employed 260 000 people, to assess risks posed by global climate and trade policy, as well as the potential opportunities the transition presented for the sector.

“We need to assess the technological choice combinations that are appropriate for the value chain … and understand the policy support environment and the basket of supportive tools that can be used to ensure decarbonisation and a just transition of the sector,” Patel said.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation