Spray drop size in dust suppression

Drop size plays a critical role in the effectiveness of dust suppression applications. The size of the droplets produced by spray nozzles has a direct impact on their ability to capture and suppress dust particles. Spray nozzle selection is the most important element in a successful dust control system.

Here are some key reasons why drop size is important in dust suppression:

- Dust particle capture: Droplet size affects the efficiency of capturing and binding dust particles. In general, smaller droplets have a larger total surface area compared to larger droplets of the same volume. This increased surface area allows smaller droplets to effectively capture and bind with dust particles, facilitating their removal from the air.

- Dust settling: Larger droplets have more mass and inertia, enabling them to settle more quickly. When droplets collide with airborne dust particles, the collision causes the particles to agglomerate and become heavier, facilitating their gravitational settling. This settling process helps remove dust particles from the air, reducing the inhalation risk and preventing dust re-entrainment.

- Avoiding mist formation: While small droplets are effective for dust particle capture, excessive production of fine mist can lead to mist formation. Mist can create visibility issues, wet surfaces excessively, or result in the formation of aerosols that may pose health risks. Therefore, striking a balance between droplet size and mist formation is crucial in dust suppression applications.

- Coverage and penetration: Droplet size affects the coverage area and penetration depth of the spray. Smaller droplets tend to disperse more easily in the air and can reach greater distances, providing wider coverage. On the other hand, larger droplets may have better penetration capabilities, reaching deeper into the dust-laden atmosphere or dense material layers.

- Wind drift and evaporation: Droplet size influences susceptibility to wind drift and evaporation. Smaller droplets are more susceptible to wind forces and may be carried away from the intended target area, reducing their dust suppression effectiveness. Additionally, smaller droplets have a higher surface-to-volume ratio, making them more prone to evaporation before they can reach and capture dust particles.

- Environmental considerations: The size of droplets produced during dust suppression can impact the environmental impact of the process. For instance, larger droplets may lead to excessive water usage and runoff, potentially affecting surrounding ecosystems or creating a muddy environment. Optimal droplet size selection helps minimise water consumption while achieving effective dust suppression.

- Regulatory compliance: Droplet size requirements may be specified by regulatory standards or guidelines in certain industries or applications. These standards ensure that dust suppression systems are designed and operated to meet specific performance criteria. Adhering to the recommended droplet size ranges ensures compliance with regulatory requirements.

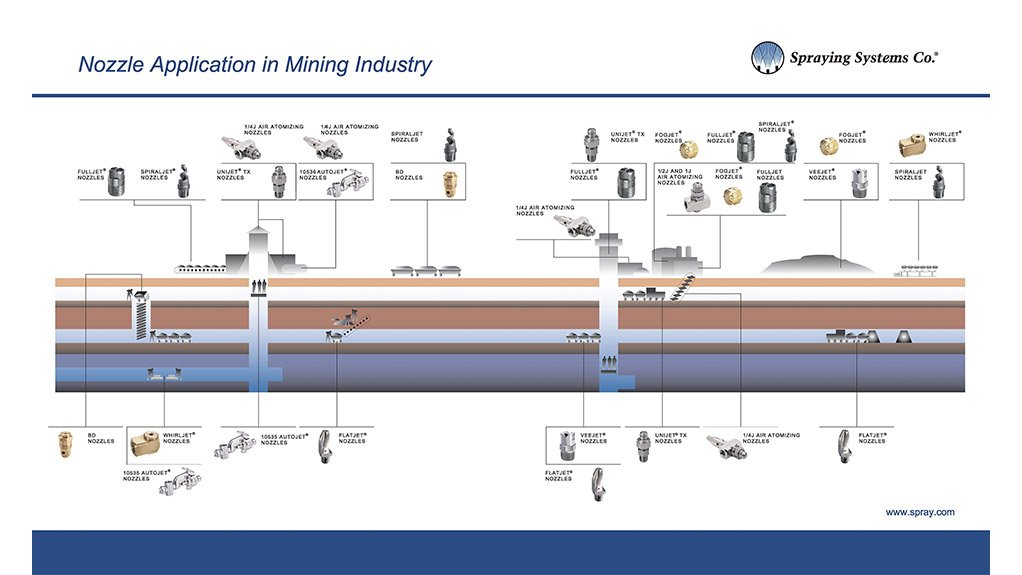

It is important to note that the ideal droplet size for dust suppression depends on various factors, but most importantly on spray nozzle type and operating pressure. Success in controlling dust does not rely on a “one size fits all” solution. Typically, several different types of spray nozzles are required in a dust suppression system.

Working with a spray nozzle specialist who understands nozzles and drop size, and has drop size data on their spray nozzles, is the key to successful dust control.

Spray technology manufacturer Spraying Systems Co is the world leader in spray technology. It pioneered drop size measurement and provides actual tested drop size data on its spray products.

Spraying Systems Co offers cost-free audits of dust suppression applications and provides audit reports on proposed dust control solutions.

011 618 3860

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation