Use of synthetic lubricants growing in local industry

LOCAL MARKET UPTAKE While the ratio of full synthetic lubricants to conventional lubricants is still low, it is growing yearly by 5% to 8%

HIGH BREAKDOWN RESISTANCE The components used in synthetics are high in purity, with strong molecular bonds, resulting in the lubricant being a pure compound

SUSTAINABLE SAVINGS BMG’s synthetic gear technology has shown an increase in the viscosity index and oxidation stability, allowing for improved energy savings and longer oil life

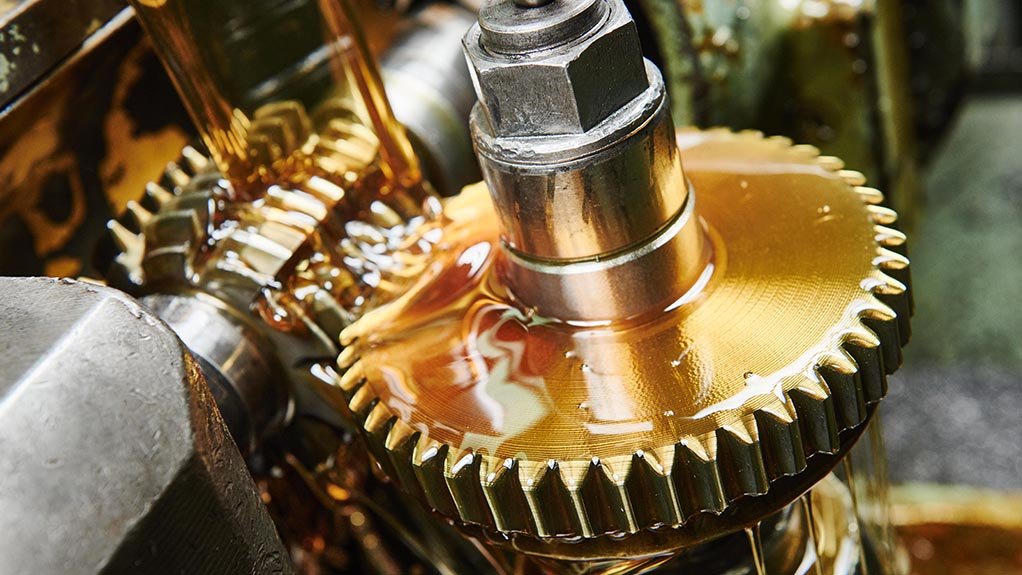

Synthetic lubricant use in the local industry as a viable alternative to conventional, hydrocarbon- and mineral-based lubricants is gaining momentum, says industrial equipment and consumables supplier BMG fluid technology business unit manager Willie Lamprecht.

The lubricants are engineered products created by chemical reactions through the precise application of pressure and temperature to a specific recipe of components.

“Previously, the use of synthetic lubricants was an option only when conventional lubricants had reached their performance limit and could no longer meet specific application requirements. Today, original-equipment manufacturers (OEMs) consider synthetic lubricants as an integral part of the development of various types of machinery.”

While the ratio of full synthetic lubricants to conventional lubricants is still low, it is growing yearly by 5% to 8%, which is mostly attributed to OEM activity and increased awareness of synthetics from younger maintenance engineers, Lamprecht argues.

All the components used in synthetics are high in purity, with strong molecular bonds. Owing to this, the lubricant product is a pure compound, less vulnerable to oxidation and highly resistant to breakdown.

These factors can result in a number of benefits, including low- and high-temperature viscosity performance at service temperature extremes, a better viscosity index, possibly a longer engine life and an improved fuel economy in certain engine configurations.

Synthetics also provide a better chemical and shear stability, decreased evaporative loss, and possibilities for extended drain internals, with the environmental benefit of less used oil waste generated.

Lamprecht says there are various types of synthetic lubricants available, with each serving a specific purpose in modern engineering.

Temperature and temperature-related characteristics are considered as the most common, “owing to their molecular uniformity, which helps synthetics resist thinning in hot temperatures. Synthetics’ unique design translates into better thermal, chemical and oxidation stability. It is well understood that the life of a conventional lubricant reduces dramatically when exposed to higher operating temperatures”.

Traction coefficient is another lubricant attribute that improves a machine’s efficiency, and reduces energy and fuel consumption. Synthetic lubricants, by design, have a lower traction coefficient than conventional lubricants.

Cost Considerations

While customers are sometimes hesitant to use synthetics, owing to their higher cost, Lamprecht stresses the underlying value that synthetics can add to their businesses.

Depending on the product and type of synthetic, the cost ratio of conventional to synthetic lubricants could be 1:3 or 1:4.

In most instances, the payback could be as soon as six months, but a year in most cases, he adds.

This value also includes reduced maintenance costs – which has become crucial amid global supply chain constraints reducing the availability of parts – as well as energy savings, reduced inventory control and longer oil drain intervals.

“Several well documented successes of the use of synthetics can easily be transferred to customers. Energy-savings calculations can be extrapolated into real value, such as reduced electricity and fuel bills, as South Africans are faced with high fuel costs, disrupted electricity supply and future tariff rate hikes.”

While appropriate applications for synthetic lubrications vary, Lamprecht notes that extreme operating environments, such as the cement and mining sectors, are “easy targets” for which to showcase the benefits of synthetics.

BMG Offering

BMG specialists recommend the use of synthetic lubricants as part of a company’s commitment to improving operational efficiencies, extending the service life of equipment and enhancing environmental protection.

Lamprecht adds that BMG’s synthetic lubricants have been developed through joint efforts, locally and abroad, and that there have been advancements in synthetic gear and compressor-oil formulations.

“BMG’s synthetic gear technology has shown an increase in the viscosity index and oxidation stability. Both these characteristics allow for improved energy savings and longer oil life.”

Compressor oils have also been improved through the use of more stable additive technology, which allows for better oxidation control, he adds.

The company’s synthetic gear technology product has recently been formally approved, and is awaiting additive technology to launch locally.

Meanwhile, BMG is active in most industries in sub-Saharan Africa, which enables the company to promote several OEMs. The company also has its own fully equipped service and maintenance centres.

“All heavy industries are aware of the benefits of using synthetics, but customers in these sectors have their own perception on whether synthetics are needed. Compressor oils and industrial-gear oils are by far the largest of the local synthetic oils market, and the latter has been researched and trialled by State-owned power utility Eskom. Our opportunities lie with BMG’s contracted business, and its well-versed fluid-technology team,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation