Technology at the fore

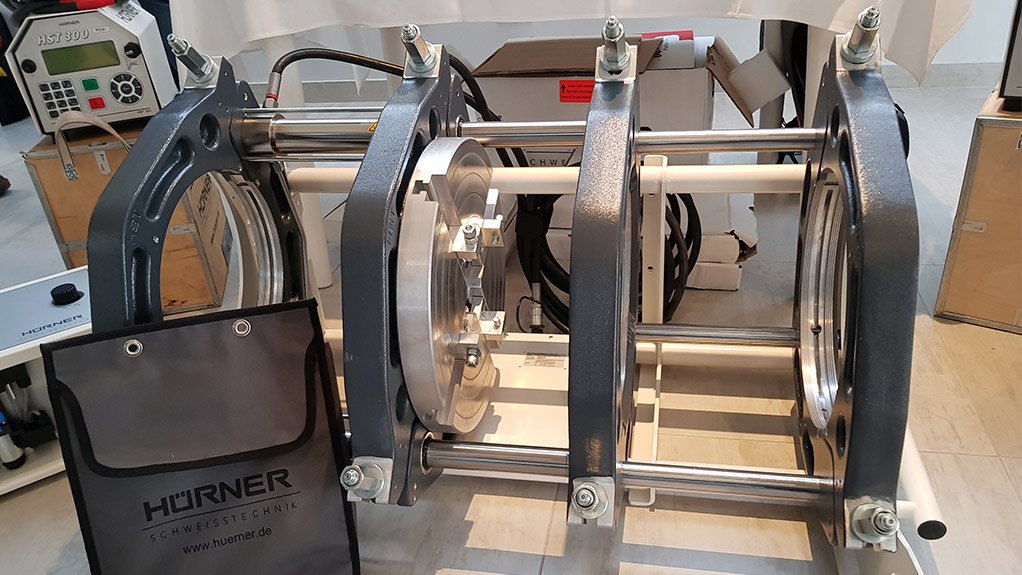

PRODUCTS ON DISPLAY The new Hurner Smartline butt welding machine and clamp was on show

Various speakers discussed new technologies and applications in the thermoplastic welding industry at the Thermoplastics Welding Technology Day, hosted by industry body Plastics SA last month.

The discussions ranged from single-user welding technology to new applications (apps) revolutionising the traceability of a weld.

Piping systems company Plasti-Tech founding member Brad Chamont, representing industrial manufacturer Hurner Welding Equipment, discussed how apps and technology have assisted with data transfer and accountability where welds are concerned. “The CNC Ecoline 2.0 welder not only holds a 10 000 weld memory but is now also Bluetooth enabled and ties in with a weld-trace app.”

The app, available for Android and Apple through a DataWorks programme, compiles all of the welds parameters which can either be downloaded to a USB or printed on an abrasion-proof plastic sticker, with a quick response (QR) code. This carries all the weld information, such as the size of the pipe, the standard dimension ratio, and even the time of day.

“The client can select whatever information they want included on the QR code, in addition to the standard weld information. The relatively new technology, launched in the beginning of the year, allows full traceability of a weld,” notes Chamont.

Plastic products supplier Plasti-Weld sales manager Clinton van Zyl mentioned that the company was the sole distributor of Italy-based welding company Ritmo’s Easy Life range. He also discussed Ritmo’s Easy Life system, which now allows for single-user welding operations.

“The Easy Life system enables a welder to set up the weld parameters, perform the weld by simply pressing a button, open the carriage while still focusing on the heat plate removal and, finally, adjust the pressure in case of eventual drops,” explained Van Zyl, who added that using the system resulted in fewer mistakes by repeating results automatically from the present parameters.

“Ritmo also carries new software that is compatible with a “Set + Go Pro!” app, which also allows for the traceability of welds”, said Van Zyl. This technology shares its information through Bluetooth, Wifi and Cloud, and is enabled with global positioning system tracking.

Thermoplastic pipe supplier Astore Keymak machines technician Janu Pretorius discussed the company’s ability to manufacture customised equipment to client specifications. The made-to-order equipment for the welding of eccentric tee’s, double crosses and filtrations systems are manufactured in Italy and distributed from Astore Keymak’s Boksburg branch.

Astore Keymak also offers clients repairs and calibration on all of its machines aligned with European Union and manufacturer specifications. “We are also importers of the Italian Tecnodue, German Munsch and French CTF welding machine brands,” Pretorius noted.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation