Testing can ensure safe communication on mines

SAFER, DEEPER MINING From its inception, Ya Batho decided to make products appropriate in explosive environments and close to electronic equipment, without interference, to adhere to mining regulations

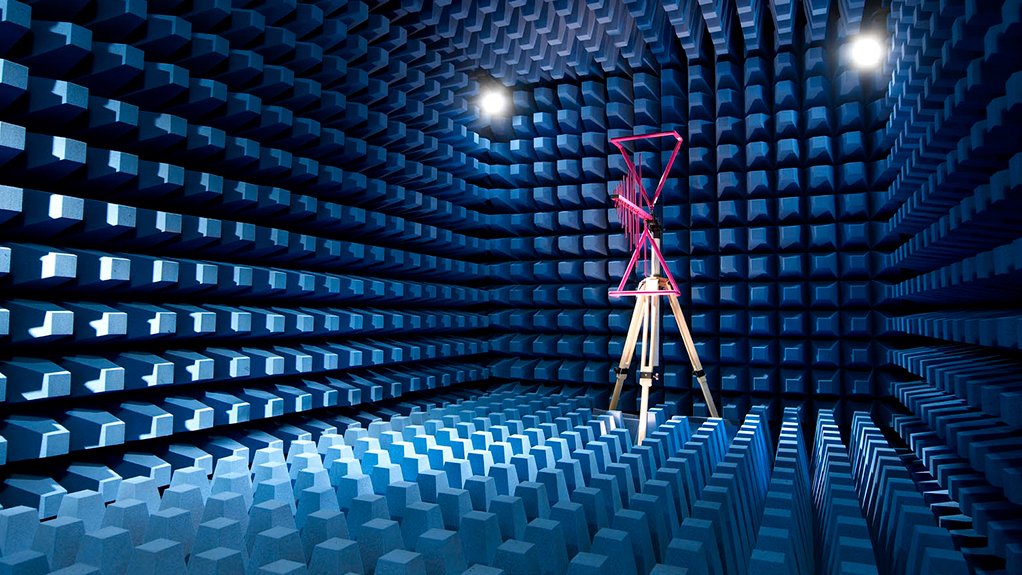

TESTED FOR UNDERGROUND Electronic equipment, including phone, tablet or wireless access points, need to be subjected to EMI/EMC testing to ensure the PDS and CAS are not compromised

The potential dangers of working underground make reliable communication vital for improving safety and enhancing operational efficiency, says communications device provider Ya Batho sales and operations manager Craig Franck who stresses the importance of using wireless communication equipment that has passed stringent safety and compatibility testing.

“It is one thing to develop technology and introduce commercially available communication equipment to the mining industry; it is something totally different to pass South African National Standards accreditation,” he claims.

The Mine Health and Safety Act stipulates that all electronic equipment used in the mining sector must undergo electromagnetic interference testing.

Further, a proximity detection system (PDS) and a collision avoidance system (CAS) are critical for mine safety. This means that all electronic equipment, including phone, tablet or wireless access points, need to be subjected to electromagnetic interference and electromagnetic compatibility (EMI/EMC) testing to ensure the PDS and CAS are not compromised.

This legislation led to Ya Batho’s decision, from the company’s inception, to make products that could be used safely in explosive environments and in close proximity to electronic equipment, without interference, while adhering to mining regulations.

Franck points out that Ya Batho, as a supplier of wireless communication products, has received the approval of the Department of Mineral Resources and Energy (DMRE). The company’s products can, therefore, be used while standing next to an operational continuous miner.

Further, underground coal mines also need to ensure that all equipment used in the inby has undergone SANS 61000 and ISO 7637-2 testing and complies with DMRE directive ME-2-2003.

He adds that coal mines will also have fixed-line communication available in the outby, to make communications available in the inby. For this reason, products need to be certified as intrinsically safe and pass the SANS standards and EMI/EMC testing.

The DMRE directive also stipulates that the maximum transmitted power of wireless transmitters and cellphones used in mines be limited to 500 mW.

Digital Focus

Franck notes that the Covid-19 pandemic has illustrated the need for connectivity, and Ya Batho’s capability to provide reliable and scalable connectivity.

“Digital technologies are now ‘front and centre’, with mines looking at semi- and fully autonomous mining capabilities. There has never been a stronger need for the industry to create modern mining solutions to improve remote working and continue to optimise its functionality, even post-Covid.”

Wireless communication, combined with real-time location, continues to offer growth opportunities for Ya Batho in local mining, he adds.

Franck states that, with more data being made available from original-equipment manufacturers (OEMs), “a reliable and scalable solution is imperative”.

Ya Batho will, consequently, introduce new technology-driven solutions to improve safety and production efficiency.

Further, more emphasis is being placed on asset location so that mines can monitor and control the use of their assets and spares.

In this regard, Ya Batho’s YNSIGHT software platform allows for a clear view of the location of the materials handling equipment and spares throughout the mine.

The mine can also see when someone enters or leaves a defined area and, if a movement is detected, the relevant department head receives a notification.

YNSIGHT also allows for automated reporting, which shows the mine how its assets are being used, consequently enabling them to identify bottlenecks and make informed decisions.

Applications such as shaft clearance, blast clearance and aiding personnel in distress can be achieved using technology provider Quuppa’s intelligent locating system, and Bluetooth, low-energy wearables.

“Mines want to make informed decisions based on real-time data, and Ya Batho makes the OEM machine health and productivity data available in real time. Our motto is ‘data drives decisions’. The ability to monitor the production fleet in real time has proven to be beneficial.”

Franck says the company has received requests from mines in Australia and North America over the past five years to supply wireless access points and intrinsically safe phones and tablets.

Ya Batho is obtaining industry standard bodies Equipment for Potentially Explosive Atmospheres (ATEX) and Electromechanical Commission System for Certification for Standards Relating to Equipment for Use in Explosives Atmospheres (IECEx) certification.

These certifications are awarded to equipment that has been rigorously tested in accordance with European Union directives, and has proven safe to use in specific environments with explosive atmospheres, specific to the zones in which they are certified for use.

“Ya Batho aims to be the vendor of choice for wireless connectivity and communication devices, with a reputation of continually exceeding client expectations and delivering outcomes others never experience or expect,” Franck concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation