The critical role of insulation in rotating machine performance in harsh environments

When it comes to electrical rotating machine performance and longevity, one factor is often underestimated but absolutely vital: insulation quality. The insulation system within an electrical rotating machine is not just a passive barrier; it is a fundamental component that determines the machine’s ability to perform efficiently, reliably and safely, especially under harsh environmental conditions.

Electrical rotating machines operate under a range of stresses, including thermal, electrical, mechanical and environmental. The insulation system acts as a shield that protects the machine windings from these stresses, preventing short circuits, reducing energy losses, and ultimately safe-guarding the machine from premature failure. High-quality insulation ensures the electrical rotating machine can maintain its performance over time, regardless of demanding operating conditions.

Insulation quality becomes even more critical in industries such as mining, petrochemicals, marine and heavy manufacturing, where machines are routinely exposed to high humidity, extreme temperatures, dust, chemical vapours and mechanical vibrations. In these settings, even a minor flaw in insulation can lead to catastrophic breakdowns and hazardous working conditions.

Effects of Poor Insulation

A degraded or poorly applied insulation system leads to a host of issues. First, the machine’s dielectric strength is compromised, increasing the risk of winding faults and electrical break-downs. Overheating becomes more prevalent, and thermal stresses can cause further damage to insulation

layers, forming a vicious cycle that accelerates the machine’s deterioration.

Further, partial discharges and insulation tracking can develop when the system is exposed to contaminants or high-voltage spikes. These issues might not cause immediate failure but contribute to a slow and silent decline in motor health, eventually leading to sudden breakdowns.

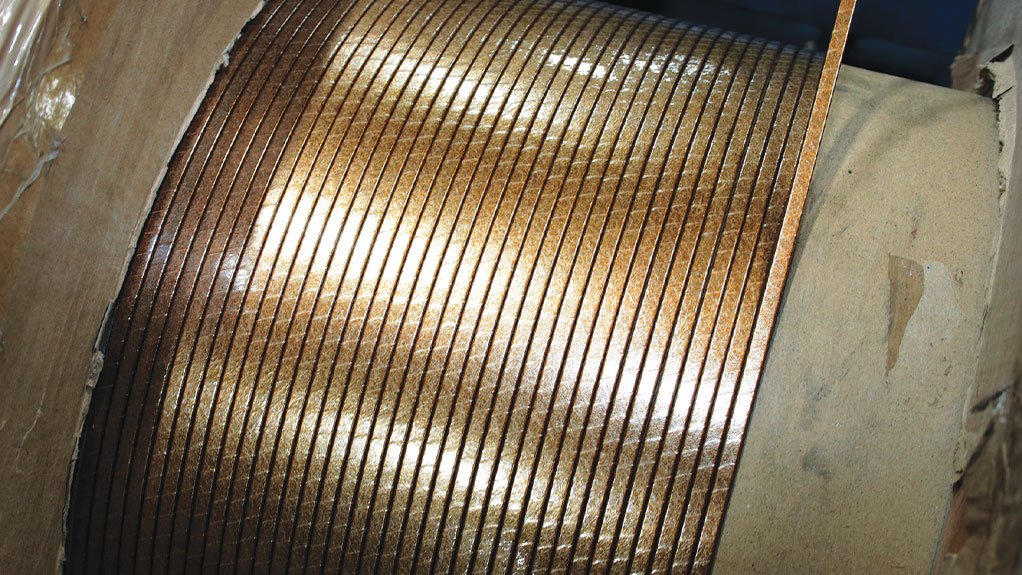

It is for this reason that electrical rotating machine repairs and maintenance specialist DELBA Electrical places exceptional focus on insulation quality throughout the repair and refurbishment process. Whether it is rewinding a traction motor, a DC machine, or a high-voltage industrial machine, DELBA ensures every component is insulated to the highest standard.

DELBA’s state-of-the-art vacuum pressure impregnation facilities, which are among the largest and most advanced in Africa, enable it to deeply penetrate insulation materials into windings. This Class-H process significantly improves the thermal and mechanical integrity of the insulation, resulting in electrical rotating machines that are more resistant to moisture ingress, vibrations and thermal cycling.

Additionally, DELBA’s insulation materials are rigorously selected and tested for high dielectric strength, thermal class stability, and resistance to chemical degradation. Its artisans are trained to apply and cure insulation systems meticulously, ensuring consistent and reliable results.

Extending Machine Life in Harsh Environments

With the right insulation practices, motors can operate for decades, even in the toughest environments. By investing in high-quality insulation during electrical rotating machine repair or refurbishment, plant operators can reduce maintenance costs, avoid unplanned downtime, and improve overall energy efficiency.

Moreover, machines with superior insulation systems tend to run cooler, which directly enhances energy efficiency and reduces operating costs.

Insulation quality is not a secondary concern—it is a core determinant of machine performance, reliability and safety. In harsh operating environments, it becomes the first line of defence against failure. At DELBA Electrical, the focus on insulation excellence ensures that every electrical rotating machine leaving its facility is equipped to meet and exceed the challenges of its environment. When insulation is done right, performance follows.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation