Receive our free daily newsletter:

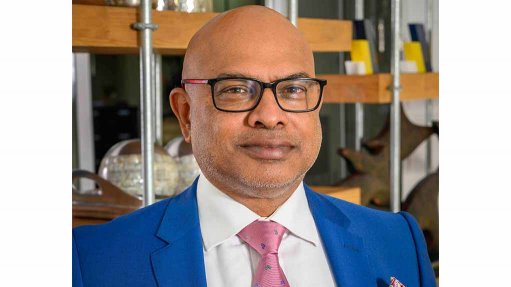

Pumps manufacturer Weir Minerals Africa is the partner of choice for the majority of mining operations in Africa, winning 95% of projects owing to the company’s footprint, the scale of its...

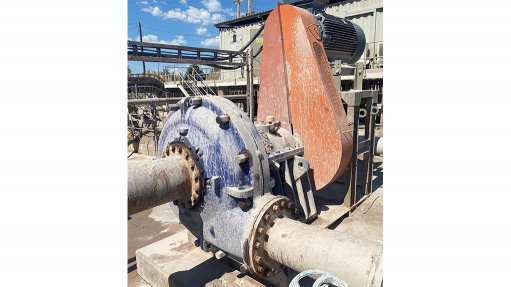

A recently installed pan feeder at a local crushing plant is said to have increased production by 40% and helped create a safer working environment. Weir Minerals Africa installed the Trio EF3606...

Judging from interactions with mining customers at Electra Mining Africa 2022, Weir Minerals Africa notes that there is a growing demand for digital integration, which provides mines with data to...

Weir Minerals Africa demonstrated an array of products at the recent Electra Mining Africa exhibition. “Having a very broad spectrum of cutting-edge pump options at our disposal allows us to offer...

High pressure grinding roll (HPGR) technology has been traditionally used for cement grinding and diamond applications, but is increasingly also being used in hard rock applications such as copper,...

A history spanning 150 years of strategic development has positioned minerals processing equipment firm Weir Minerals as one of the few companies to provide holistic services and integrated pumping...

Equipment and solutions provider Weir Minerals Africa, which enjoyed excellent attendance at its stand at the last Electra Mining Africa in 2018, will once again be exhibiting its extensive range...

Weir Minerals’ high pressure grinding roll (HPGR) technology is fast becoming the staple for an increasingly diverse range of hard rock mining applications. Although iron ore accounts for the...

Minerals processing equipment firm Weir Minerals Africa, which enjoyed excellent attendance at its stand at the last Electra Mining Africa in 2018, will once be exhibiting its range of equipment at...

Integrated solutions are what separates equipment suppliers from solution providers, argues Marnus Koorts, general manager pump products at Weir Minerals Africa – and the recently launched...

Weir Minerals Africa, which enjoyed excellent attendance at its stand at the last Electra Mining Africa in 2018, will once again be exhibiting its extensive range of minerals processing equipment...

As industries have developed, customers’ equipment demands have increased. As such, equipment and solutions provider Weir Minerals Africa has found that continuously engineering product solutions...

Boosting manufacturing quality and consistency at Weir Minerals Africa’s Isando foundry and rubber plant, two laboratories recently opened their doors at the company’s facility near Johannesburg....

As Zambian mines move to adopt more sustainable mining practices, the reduction of energy use, water consumption and carbon emissions – as per global mining trends – is a significant priority, says...

Weir Minerals Africa, part of the LSE-listed Weir Group, is currently performing strongly, more than maintaining its share of the African market and also moving into new geographies on the...

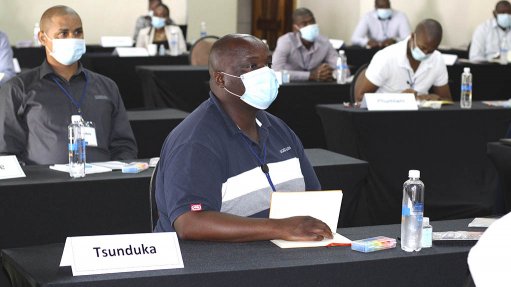

Designed to train customer-facing Weir Minerals Africa employees, the company’s Mill Circuit University (MCU) equips its learners with the fundamental knowledge to better understand the end-users’...

Optimising water use is a priority for equipment supplier Weir Minerals Africa – it is an area that can often be overlooked but contributes significantly to a mine’s environmental, social and...

Weir Minerals Africa, part of the LSE-listed Weir Group, is currently performing strongly, and is more than maintaining its share of the African market, while also moving into new geographies on...

Original-equipment manufacturer Weir Minerals Africa is continuing its strong focus on sustainability across its West African operations. With the company’s fully integrated, customer-centric...

Optimising water usage is a priority for Weir Minerals Africa – it is an area that can often be overlooked but contributes significantly to a mine’s Environmental Social and Governance (ESG) drive...

Mines are well aware of the significant cost savings that can be achieved by using rubber to increase the wear life of equipment; however, selecting the right product for the application is vital....

It has been 10 years since Weir Minerals Africa sold its first Warman® DWU (dirty water unit) pump, with the locally developed and manufactured innovation achieving success in Africa and abroad....

Rubber lining is a highly skilled process which, when done correctly with the correct type and thickness of rubber, can contribute considerably to the life and profitability of a plant, affirms...

Underpinning the popularity of Envirotech® pumps is Weir Minerals Africa’s ongoing investment and support, as well as the pumps’ integration into various pumping solutions that the company offers....

The Envirotech pumps range from pumps manufacturer Weir Minerals benefits significantly from synergies in research and technology development, as well as application knowledge sharing across a...

When the Cavex® hydrocyclone was introduced to the industry over 20 years ago it set the benchmark for the rest of the market. The recently launched Cavex® 2 took this product range a step further...

Vulco® rubber is renowned throughout the mining industry for its exceptional wear life and reliability in mill lining systems. These abrasion- and impact-resistant rubber compounds have been...

Mines are well aware of the significant cost savings that can be achieved by using rubber to increase the wear life of equipment, however selecting the right product for the application is vital....

Customers in the mining industry increasingly expect to be able to partner with companies that have insight and understanding of operational contexts and are able to offer sustainable solutions to...

By giving its personnel the ‘big picture’ of minerals processing, the Weir Minerals Mill Circuit University ensures that customers benefit from a broader, solution-focused approach. “Offering...

South African rubber hose manufacturer Weir Minerals Africa designs and builds mining hoses from 50 mm to 1 000 mm nominal bore up to 10 m in length and up to 1 100 mm bends. The hoses are designed...

Weir Minerals’ focus on development and continuous product improvement has contributed to the success of the company’s Warman mill circuit (MC) pumps. Mill circuit pumps, the largest pumps in the...

As an integral part of a mine’s minerals extraction circuit, mill circuit (MC) pumps handle large rock fragments from the primary mill, which can rapidly wear the pump’s throat bush, impeller and...

Doing duty as an integral part of a mine’s minerals extraction circuit, Weir Minerals’ Warman® mill circuit (MC) slurry pumps withstand the harshest conditions while delivering their...

A double-layered rubber lining solution installed on a mill discharge chute is said to have achieved a 250% wear life improvement compared to the competitor product. Weir Minerals Africa was asked...

Weir Minerals’ Linatex® Premium Rubber and Linard® 60 have significantly improved wear life at Kalumbila Minerals Limited’s Sentinel mine in Zambia, after the Weir Minerals Africa team was asked to...

A hard wall mining hose built for suction and discharge applications was recently installed at a treatment plant in Namibia, helping to reduce downtime and operating costs. The existing rubber...

Since adding the Accumin range of lubrication systems to its portfolio of products and solutions in 2020, pumps original-equipment manufacturer Weir Minerals Africa says the system has generated...

Lubricating of pumps is considered to be a time consuming and labour-intensive process that can be difficult to control and to conduct with precision. Pump failure owing to lack of regular...

The installation by Weir Minerals Africa of a Linatex® 808 hard wall rubber hose with wear indicator system is reducing downtime and operating costs at Namdeb’s Sendelingsdrift treatment plant in...

Selecting the correct type of valve for a given application is not only critical to plant uptime, but it will also assist in maintaining the lowest total cost of ownership on a plant or other...

Weir Minerals’ Cavex® classification hydrocyclones have added value to two more African mines; one is a gold mining operation and the other mines fluorspar. Following the retrofitting of two...

Specifying pumps for mine water applications is not as simple as it would first appear, and these applications often require a bespoke solution, says original-equipment pumps manufacturer Weir...

Research Reports

Projects

Latest Multimedia

Latest News

Showroom

Goodwin Submersible Pumps Africa is sole distributors for Goodwin electrically driven, submersible, abrasion resistance slurry pumps.

VISIT SHOWROOMRooted in the hearts of South Africans, combining technology and a quest for perfection to bring you a battery of peerless standing. Willard...

VISIT SHOWROOMFor over 30 years, Werner South Africa Pumps & Equipment (PTY) LTD has been designing, manufacturing, supplying and maintaining specialist...

VISIT SHOWROOMATI systems comprises five divisions: electrical assemblies, drives and controls, feedback sensors, enclosures, and strip guiding.

VISIT SHOWROOMWeir is a global leader in mining technology. We recognise that our planet’s future depends on the transition to renewable energy, and that...

VISIT SHOWROOMAs one of South Africa's leading manufacturers, Bell Equipment distributes and exports its wide range of heavy equipment globally to mining,...

VISIT SHOWROOMPress Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation