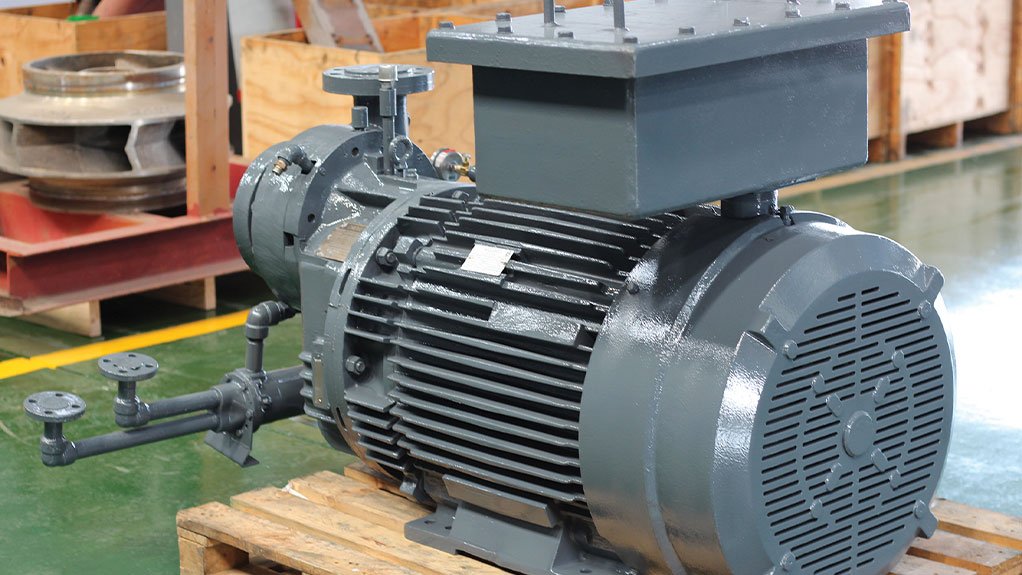

AESPUMP: Leading pumping solutions company providing expert repair services

AESPUMP is a leading provider of pumping solutions, offering top-quality repair and maintenance services for all types of pumps, compressors, and fans. Established in 2012, the company was founded as the Secunda-based rotating equipment repairs division of its sister company AESSEAL.

Since then, AESPUMP has grown into a prominent player in the industry, with two state-of-the-art facilities located in Secunda and Sasolburg.

AESPUMP facilities and quality control systems ensure top-notch services

The company’s commitment to quality is evident in its ISO 9001 compliance certification and its rigorous quality control processes. The AESPUMP team has a massive 240 years’ combined experience in Secunda alone, and is fully equipped to handle high workloads and large-sized pumps of up to 20 t.

Trusted by Sundyne: AESPUMP’s expertise in high-quality pump services

As an authorised channel partner for Sundyne (including Marelli, LMV, HMD’s and Compressors) AESPUMP is uniquely positioned to deliver the highest quality maintenance, repair, and overhaul services for all Sundyne pumps. Its team of expert technicians is fully trained to provide fast and efficient service, ensuring minimum downtime and maximum uptime for customers’ operations.

Sundyne’s vast array of products include fully packaged and engineered pump skids for all industry applications, as well as a wide variety of upgrade or debottling projects.

Typical process applications include:

Upstream and midstream oil and gas production, refining, petrochemical, chemical, power and water process industries

Marelli’s single and multi-stage pumps

- Overhung, between-bearings and vertically suspended centrifugal pumps, complies with the demanding API 610 and ISO 13709 standard requirements

Sundyne’s compressors and pumps for processing industries

- High speed integral gear pumps comply with API 610 and ISO 13709 standard requirements

- HMD sealless pumps designed to meet stringent industrial regulations including API, ASME, ANSI, DIN and ATEX.

In addition, AESSEAL provides appropriate mechanical seal and support system solutions during the selection of a suitable application for the required process.

AESPUMP together with Sundyne, offers its customers a complete project management process phase through engineering, procurement and construction (EPC) for design, material procurement, manufacture, fabrication, inspection, works performance testing, packaging, and delivery for the required applications.

AESPUMP’s specialisation in the petrochemical industry enables it to provide specialised services for all petrochemical pumps. The company has extensive knowledge and experience in the repair and maintenance of these pumps, ensuring that they operate safely and efficiently. Its commitment to quality ensures that all Sundyne pumps are serviced to the highest standards, with minimal downtime, to keep clients’ operations running smoothly.

Asset Management: Condition-based monitoring the key for overall equipment health

AESPUMP’s specialised services utilising integrated solutions, aim to address the overall health of equipment and related systems.

The condition-based maintenance platform allows for:

- Monitoring of overall performance with full spectrum vibration analysis and trending with maintenance inspections to ensure easy maintenance of equipment

- To assist fault finding AESPUMP’s non-invasive field flow measurement instrument indicates the operational efficiency of a pump

- Collection and exchange of reliability and maintenance data through a data base management system, or site survey, which enables users to focus on the total life cycle of a installed rotating equipment

This application provides a comprehensive basis for a structured, yet flexible site hierarchy that meets the specific operational, reporting and analysis requirements of each asset, with reliability -related key performance indicators and deliverables.

Collection of strategic data for reference and analysis increases inherent performance levels through continuous introduction of new design, product development, modifications, and operating methods.

AESPUMP complies with the specified industry standards for design, manufacturing, selection and maintenance such as API682, API610, and ASME B73.1 and its comprehensive evaluations assist the justification of related upgrades to adhere to occupational health and safety requirements for general machinery regulations for safe operations. This offers a complete integrity-based specification – an industry standard practice for all pumps and sealings systems.

Beyond the basics: AESPUMP’s innovative Belzona products and applications

In addition to its range of services, AESPUMP provides access to all of Belzona’s specialised industrial protective coatings and rebuild/repair composites. Belzona, a UK-based multinational, is represented in South Africa by AESPUMP, providing customers with a wide variety of polymeric epoxy products with applications in numerous fields. Rebuilds using Belzona compounds are potentially far more cost-effective than parts replacement, which can cost up to three times more. AESPUMP utilises Belzona products to extend the life of equipment and enhance efficiency, leading to reduced operating costs.

MASC certified: AESPUMP’s unwavering focus on quality and dependability

AESPUMP is also MASC certified, demonstrating its commitment to providing high-quality flame proof repair and certification of pumping equipment in the mining industries, that meets or exceeds industry standards for safety and reliability. The MASC certification is a globally recognized quality management system that ensures compliance with rigorous standards for safety, reliability, and performance in the manufacturing of pumping equipment – assuring AESPUMP customers of the quality of the company’s pumping equipment and its commitment to providing reliable products that meet specific needs.

As a leading provider of pumping solutions, AESPUMP offers top-quality repair and maintenance services for all types of pumps, compressors, and fans. Its commitment to quality and expertise in the petrochemical industry makes AESPUMP a top-performing company in the industry. With its ISO 9001 compliance certification, Sundyne authorised channel partner status, Belzona product access, and MASC certification, AESPUMP is committed to providing the highest quality products and services to its clients while minimising downtime and maximising uptime.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation