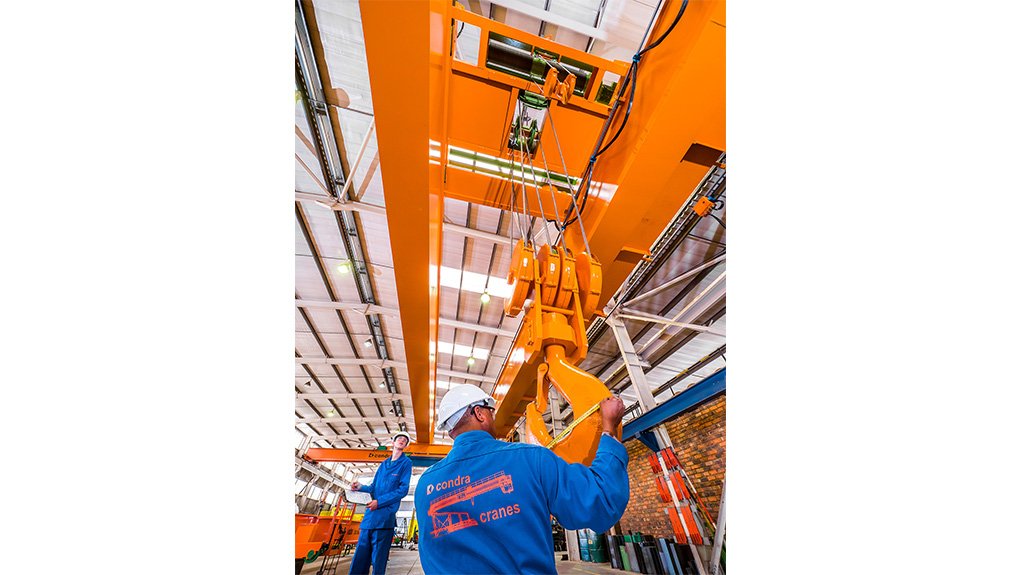

BB Cranes’ orders grow after skills transfer from Condra Cranes

Cape Town-based crane manufacturer BB Cranes has received several new orders, including an order for two Class 4 cranes, which will be the first of this class built by the company in Cape Town. This achievement is the result of skills transferred from Johannesburg-based parent company Condra Cranes.

The two Class 4 heavy-duty, double-girder overhead travelling cranes are identical in design and capable of two- and three-shift operation. The cranes also feature fast long-travel and cross-travel speeds to maximise productivity, Condra Cranes says.

The twin cranes will be installed at a factory in Wellington to produce export-grade charcoal from invasive alien trees and will move charcoal pots in a continuous cycle between kilns and the cooling and packing stations.

The 5-t cranes will have spans of 15 m and lifting heights of 9.4 m. Controlled by pendants, they will lift at speeds of up to 8 m a minute. Cross-travel speeds will be 38 m a minute, and long-travel speeds can reach up to 80 m a minute, which is equivalent to an exercise-paced walk. These speeds are notably faster than those of conventional overhead crane applications, Condra highlights.

“This order is significant for BB Cranes because it demonstrates that machines with this type of advanced specification can and are being built in Cape Town’s backyard,” says BB Cranes GM Stephen Brink Jnr.

“We have received skills transferred from Condra for this level of manufacture, and this is a big win for us. Our customers also win because the cost of importing these cranes or having them transported from Johannesburg has been eliminated.”

Further, BB Cranes will also manufacture four portal cranes for a Cape Town-based luxury catamaran shipbuilder and four overhead travelling cranes for an existing shipbuilder customer.

The portal cranes will be medium-duty Class 2 machines, marrying new end-carriages and customised legs to refurbished box girders and 5-t hoists that were originally manufactured by Condra and repurchased from a Pretoria customer, Brink says.

“An interesting aspect of this order is that the portal cranes have been designed to fit an existing factory without compromising the specified lifting height of 6.5 m. “Low-profile compact hoists from Condra’s SH-series will be used to achieve this. “They will feature gear reduction ratios, suitably modified to allow for the fibreglass catamarans to be moved efficiently and carefully, avoiding damage to their very high-quality finish.”

Delivery is scheduled for this month.

Meanwhile, BB Cranes’ second shipbuilding order is expected to be confirmed by an existing customer.

The order comprises four additional double-girder overhead travelling cranes to manage the lifting requirements of a factory expansion. The company already uses Condra cranes extensively to build its high-end yachts. The four machines will be standard units with spans of 27 m and dual hoists achieving a lifting height of 6.5 m.

Sign-off of the technical drawings for the four cranes is imminent, Brink adds.

“BB Cranes’ reputation in portal crane manufacture is growing. Earlier this year, the company delivered portal cranes to separate end-users for refrigeration systems manufacture and container handling,” he notes.

“We are optimistic about the future. Cape Town is busy. We are increasing our productive capacity and expecting orders from wastewater treatment works in George and further orders from pumpstations and waterworks closer to home.”

BB Cranes enjoys a competitive advantage in the wastewater treatment market, owing to the shot-blast zinc metal spray paint specification, which is supplied in South Africa by only one company that is also based in Cape Town.

“To help our customers meet their environmental commitments, we are focusing on the environmental aspects of our production inputs and refining our output waste recycling streams,” Brink concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation