Bearings manufacturer discusses technical paper at US conference

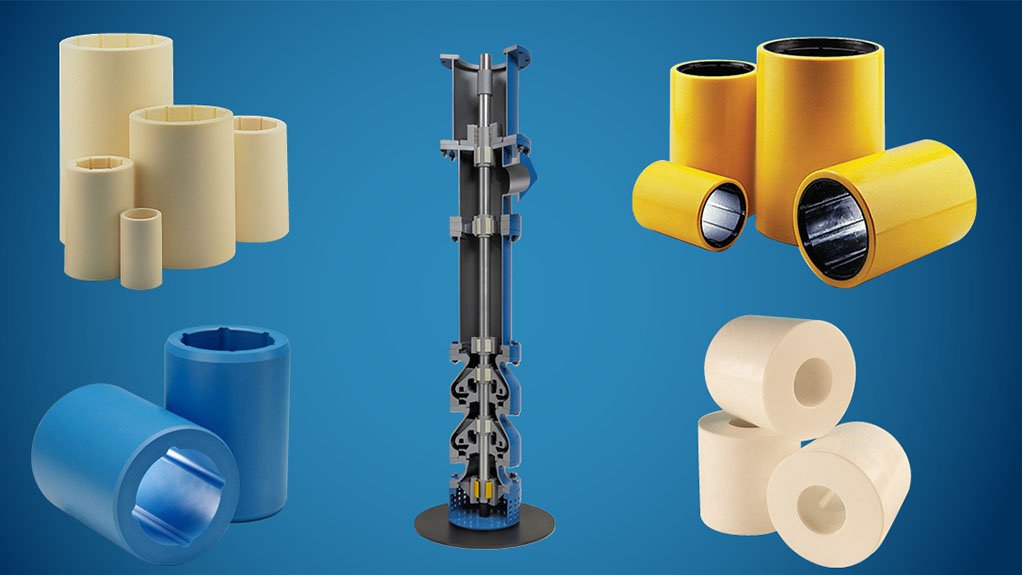

OFFERINGS Thordon’s SXL, Composite, ThorPlas-Blue and ThorPlas-White pump bearings

Bearing selection plays a critical role in vertical turbine pump (VTP) performance, but application, medium and bearing material should also be considered during pump manufacturing or refurbishment, according to polymer bearings pioneer Thordon Bearings.

“The selection of the most appropriate material for bearings is one of the most important factors affecting pump reliability,” explained Thordon Bearings strategic account manager Keith Brand in a technical paper titled ‘Selecting the Right Bearings to Improve Vertical Turbine Pump Reliability’.

Presented at an industry conference in the US earlier this year, Brand informed industry leaders that “…the nature, particularly the abrasiveness, of the pumped media, is a key variable affecting optimal pump bearing selection and life span”.

The other key variable is application, he said, noting that “abrasive wear and dry starts are the most common causes of bearing failure”.

Looking into common oil- and water- lubricated bearing materials, such as bronze, carbon graphite, thermoset laminates, Teflon, thermoplastics and elastomers, Brand explained that they all have their pros and cons.

Some bearings have better dry-running capability but poor abrasion or chemical resistance, while others may be better suited to high-temperature environments but fall short on mechanical strength. All tend to be more costly in terms of operating expenses.

“In some applications the upper bearings are not lubricated upon startup. This could mean 30 seconds or more of high-speed dry bearing operation, completely ruling out certain materials, such as rubber.

“Rubber bearings can burn up from frictional heat created with little to no lubricant and most phenolic bearings cannot handle running dry for more than 60 seconds. Here, oil-lubrication or a water flush is required to lubricate the bearings until process water can lubricate the shaft, but this also adds to the cost and can be detrimental to the environment,” he said.

Brand added that some manufacturers have attempted to make pump components more chemical and abrasion resistant by isolating the pump’s oil-lubricated bearings and shafts from process water.

“But the biggest drawback to this approach is the additional cost,” he lamented.

Going on to explore the different types of water-lubricated/grease-free polymer bearings available from the Thordon portfolio, Brand explained that Thordon has a range of products to meet the demands and challenges of many types of operating mediums and applications.

For example, the company’s composite bearing material, an elastomeric polymer alloy, is specially designed for use in highly abrasive operating environments, while the SXL material balances the operational requirement between abrasion resistance, low friction and good dry startup performance.

Meanwhile, Thordon’s ThorPlas-Blue, an engineered thermoplastic, has “excellent” chemical resistance and can also handle dry starts and operate at higher temperatures.

ThorPlas-White has the same qualities as ThorPlas-Blue, but it is designed specifically for food equipment, drinking and potable water applications and has National Sanitation Foundation/American National Standards Institute 51/61 and Water Regulations Advisory Scheme approval.

The paper included a Thordon material selection guide, showing the grades recommended for VTPs, with direct comparable reference to the key variables such as temperature limits, abrasion resistance, shaft material compatibility, pumping media limitations, dry start capabilities and more.

Summing up, Brand told conference delegates that. while there is no single correct answer to bearing selection, understanding pumped mediums and dry startup requirements will narrow down the options.

“Ultimately, understanding bearing material selection will keep pumps pumping longer, reduce downtime and maintenance costs, and prevent catastrophic failure,” he concluded.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation