Bespoke chute solutions boost mine performance

A series of custom-engineered chute solutions that address complex material flow challenges and reduce equipment wear have helped improve performance, maintenance efficiency and operational reliability at a zinc mining operation in the Northern Cape.

Weba Chute Systems has partnered with Vedanta International Zinc’s Gamsberg mine to introduce innovations such as swing doors and modified impact beds to enhance chute performance.

To simplify and speed up liner replacement during shutdowns, the company redesigned the liner pattern on the spout, explains Weba Chute Systems regional manager: Northern Cape Arnold Archer. The company also introduced a standby spout system that could be swapped out through a simple bolt-off, bolt-on procedure, to enable maintenance to be done outside of scheduled shutdowns.

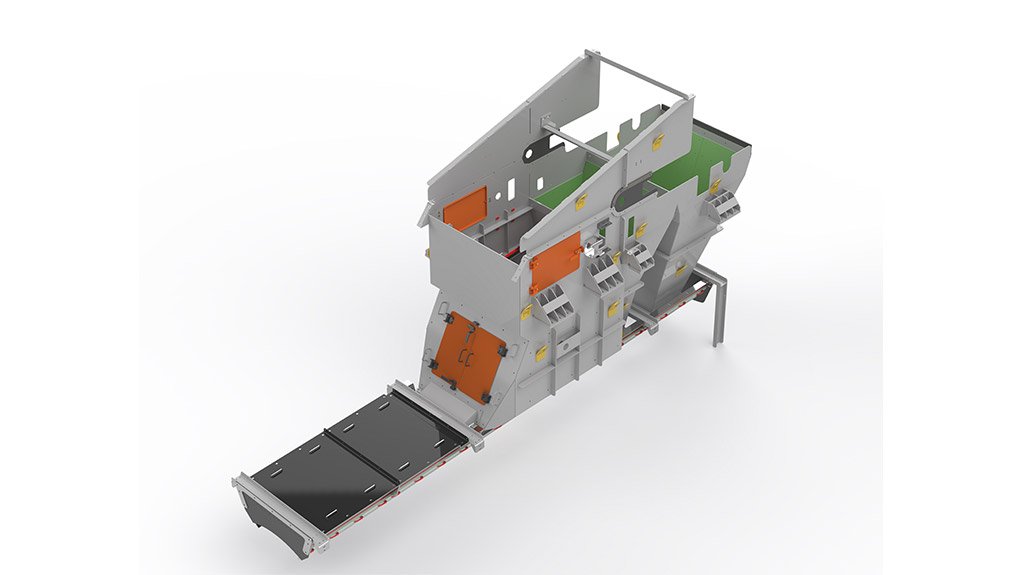

“As we demonstrated our expertise and added value, the mine invited us to assess other transfer points where they were experiencing operational challenges,” Archer explains. “These included the jaw crusher feed chute and the apron feeder discharge chute, both of which handle large run-of-mine ore lumps from up to 800 mm to 1 200 mm.”

Material arriving at the jaw crusher was moving at high velocity, leading to excessive wear and damage. After analysing the application, Weba Chute Systems proposed a solution.

“We replaced the existing jaw crusher feed chute with one of our custom-engineered designs incorporating swing doors to absorb the energy of incoming material, reducing impact and wear,” says Archer. “We later implemented the same swing door concept in the apron feeder discharge chute. Today, swing doors are also installed on the vibrating grizzly feeder and directly above the crusher – all effectively controlling flow and reducing wear.”

The company also modified the impact bed on the grizzly feeder – by raising the impact bed, incoming material begins to slow down before reaching the first swing door.

“These innovations made a significant difference, particularly in managing the impact from oversized lumps,” he notes. “We also fine-tuned door weights to optimise material flow, prevent build-up and reduce the risk of blockages.”

In addition, the mine commissioned Weba Chute Systems to install a semiautogenous grinding mill discharge chute, which accommodates a 4 m transfer height, tapering from a 2.4-m-wide screen opening to a 600-mm-wide conveyor belt.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation