Company mitigates refinery industry challenges

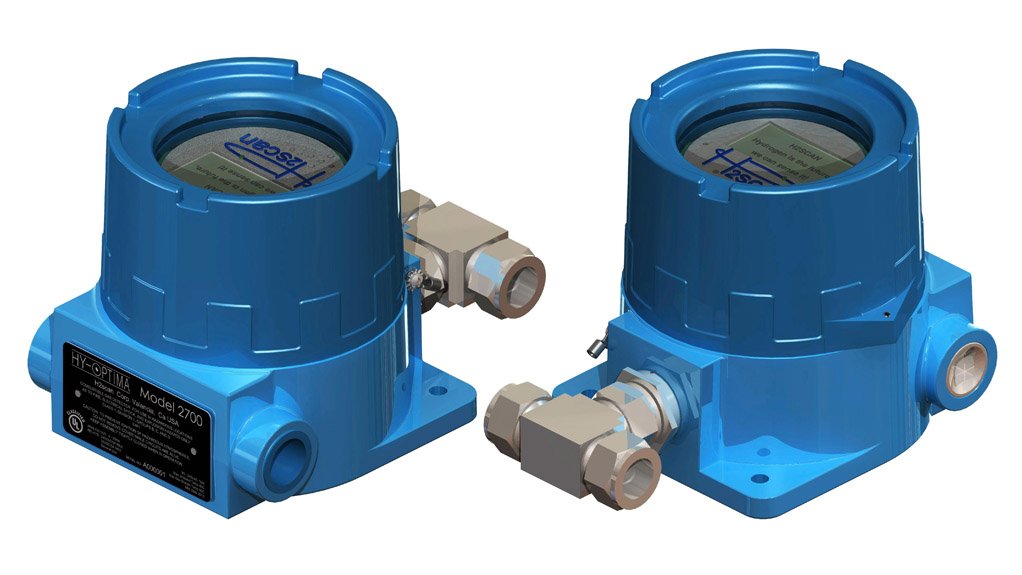

MEASURING HYDROGEN The Hy-Optima 2700 series hydrogen analysers uses a solid-state, non-consumable sensor that is configured to operate in process gas streams

Amid the weak demand and low prices that have hampered strategic decision-making and stalled planning for the oil and gas industry globally, specialised engineering company RTS Africa Engineering says improved technologies facilitating the understanding of process variables allow for cautious optimism in the future.

“We are well acquainted with the oil and gas industry in South Africa, accommodating the challenges it faces and understanding processing variables. We also have extensive experience and expertise in petrochemicals refining and the instrumentation necessary for successful oil and gas refining,” says RTS Africa Engineering MD Ian Fraser.

Understanding how petrochemicals refineries tend to be similar in design to a conventional oil refinery, is a variable that will enable the company to tailor solutions and understand plant processing procedures.

“The downstream parts of it are virtually the same, but a synfuels plant has a section that takes coal and turns it into what is essentially crude oil,” explains Fraser.

He highlights that the challenge for process engineers working at oil refineries is to monitor and control the levels of hydrogen in refining processes, particularly the monitoring of hydrogen being used in catalytic cracking and in the recycle gas stream.

Too much hydrogen results in excessive energy in the process stream, damaging the catalysts, which have a high replacement cost, conversely, too little hydrogen has a negative effect because it slows down the process, making it less economical, Fraser explains.

Currently, the traditional methods used by refineries to measure hydrogen involve using gas chromatographs, thermal conductivity meters and density analysers.

However, Fraser says traditional hydrogen analysers are costly to install and maintain. “With these traditional analysers, long sampling times prevent process engineering from making decisions based on real-time information, which could result in unacceptable variations in large product volumes.”

As a solution, RTS Africa offers the Hy-Optima 2700 hydrogen analyser manufactured by its US-based principal H2Scan, which has released progressively improved versions of the Hy-Optima over the past 15 years. This product has many benefits, including being Zone 2 explosionproof – should hydrogen get into the instrument and ignite, the Hy-Optima 2700’s robust casing will safely contain the event.

“In processing, this function is crucial, owing to hydrogen feedstock affecting the efficiency of the process stream and the quality of the final product,” avers Fraser.

The Hy-Optima range of analysers and leak detectors is based on patented, solid-state core hydrogen sensor technology, exclusively licensed from the US Department of Energy.

Fraser notes that, with the growth of oil and gas in countries such as Kenya, Angola, Uganda and Mozambique, RTS Africa is keen to offer the process-optimising Hy-Optima 2700 to new refineries that have been either recently built or will be built.

Typical applications for the Hy-Optima 2700 in refineries are reforming, cracking, recycling, tailings gas, fuelling gas, flaring gas and other multi-component process streams.

This system is easy to install and will seamlessly integrate with plants’ supervisory control and data acquisition systems and is ideal for applications where real-time hydrogen-specific measurements can enhance process plant efficiencies, diagnostics and maintenance management.

“Ultimately, with the improved measurement capability provided by this system, refineries and other process industries will be able to produce a safer and better-quality product, more time- and cost-effectively,” Fraser highlights.

Further, the main challenge with large organisations, such as major oil companies, is that they employ many people who have key performance areas. “As these organisations generate an enormous workload, employees tend to have limited fields of activity. As a supplier with a new product to offer, approaching the instrumentation or analyser department is not always successful because they are under a lot of pressure just to keep existing systems operating.”

Such organisations often do not have the time to go through the extended process of testing the products, he adds.

“As a supplier, our challenge is to establish a more direct contact with the process engineers, as they are the people who have the job of finding practical solutions to issues that might arise at a refinery.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation