Electromechanical solutions offered

IMPROVED MOVEMENT, MAXIMISED SAFETY These electromechanical solutions improve the movement of containers and goods, and maximizes safety, energy efficiency and fuel savings

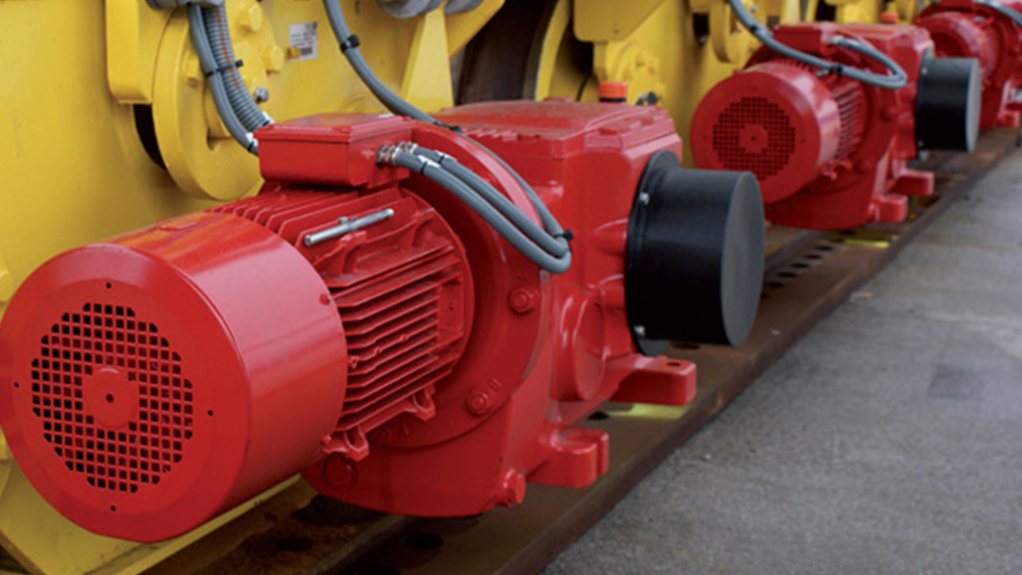

Power generation and electromechanical power transmission industry solutions provider Vert Energy – exclusive distributors for electric motor provider Leroy-Somer in Southern Africa – offers environmentally-sound automation systems and engineering services for container, dry bulk terminal and port materials handling.

These electromechanical solutions improve the movement of containers and goods, at the same time maximising safety, energy efficiency and fuel savings.

Leroy-Somer’s automation systems for port logistics operations encompass variable-speed modular drives, high-efficiency motors and a dedicated crane management system.

“In conjunction with Leroy-Somer specialists, the Vert Energy team offers port operators completely new equipment automation installation services and also has the expertise to modernise existing port installed systems,” says Vert Energy MD Grant Robertson.

This not only extends the lifetime of equipment and maximises benefits from the initial investment, but also increases safety on site and reduces operational costs, he explains. Further, its ecofriendly fuel-saving solutions minimise environmental impact, by reducing carbon emissions and decreasing equipment noise levels.

Projects vary from small logistics machine automation, to comprehensive electrical turnkey port automation solutions. Specifically, the company’s port logistics services comprise advanced drive and motor technology and scalable automation solutions. This extends from simple drive and motor conveyor or hopper control, to complete crane or port handling equipment automation solutions.

“Customised technical services encompass consultation, installation, commissioning, training, maintenance and repairs, to ensure optimum performance of port equipment.”

Robertson explains that the benefits of modular drive systems and advanced automation systems are “vast” and include fast turnaround of containers, bulk cargo or freight, by improving the loading/unloading and storage cycles.

Intelligent and safe automation solutions enhance efficiency of crane operators and also assist engineering and maintenance staff to resolve and analyse faults.

Vert Energy Leroy-Somer’s drives and motor technology has specially designed features, to make port equipment safer. These include a range of motors and brake gear motors for static hold and dynamic braking and variable-speed drive with built-in safety features for electric brake control and over speed management.

Leroy-Somer’s crane management system, which monitors the physical and operating conditions of port equipment on a real-time basis, is used to operate cranes, schedule maintenance, analyse faults, reconfigure the drives and provide crane production data.

Single or multiple crane control systems communicate with the remote crane management system (RCMS) over fibre-optic cables or through wireless communication systems, to reduce equipment maintenance and downtime.

RCMS can be used at maintenance level for service monitoring, at operations level for equipment availability and at management level for performance data.

Additionally, fault-tolerant modular alternating current-drive systems are used to control crane and handling equipment movements, with built-in redundancy for continuous operations.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation