Firm promotes multimetal corrosion protection

ECO EMITTER It is an engineered device designed to provide corrosion protection for sensitive assets

PROTECTION AND DIFFUSION The EcoMitter has vapour phase Corrosion Inhibitors emitting from the device to saturate the enclosure via diffusion

EASY-TO-INSTALL The easy-to-install device is designed to provide corrosion protection for metal components and parts enclosed in non-ventilated cabinets

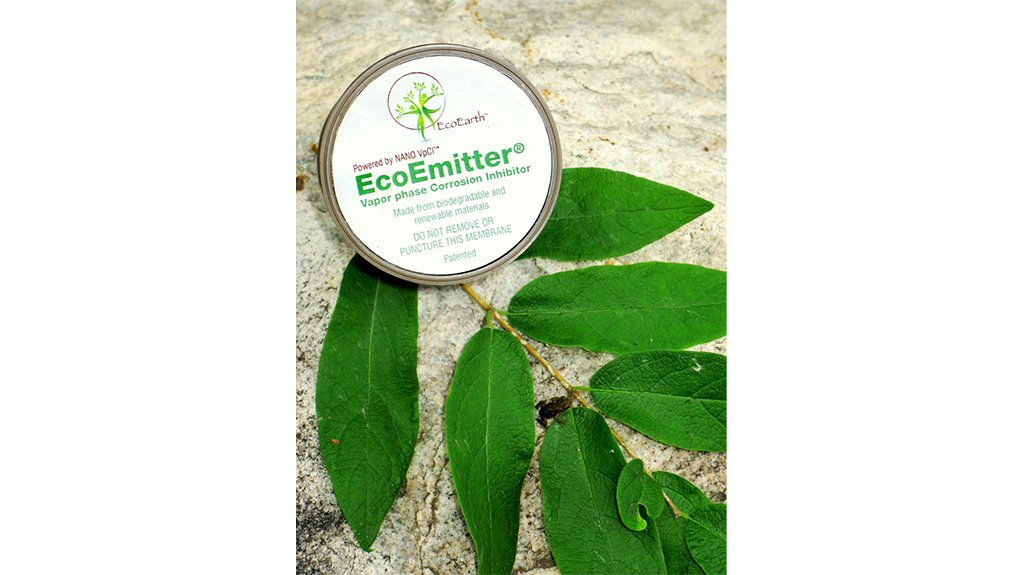

Branching from US manufacturer Cortec’s EcoEarth line, the EcoEmitter is a specially engineered device designed to provide corrosion protection for sensitive assets such as electronic and optical equipment and components.

Each EcoEmitter will protect volumes up to 0.25 m3 (8.8 ft3), with the vapour phase corrosion inhibitors (VpCI) emitting from the device to saturate the enclosure through diffusion, filling all void spaces and recessed areas with protective vapour molecules.

These molecules are attracted to and adsorb onto metallic surfaces, resulting in the formation of nanofilms, very thin microscopic molecular layers of corrosion protection. The nanofilms formed do not adversely affect or alter the appearance, conductivity, or optical functionality of the components protected.

Like VpCI-105 and VpCI-111 Emitters, the EcoEmitter was carefully designed to include biobased content as an environmentally responsible option aimed at sustainability.

The polymeric cup made from between 60% and 80% biobased resins replaces polyethylene and contains corrosion inhibiting powder that releases protective vapours through a breathable 70% biobased membrane.

This “easy to install” device is designed to provide corrosion protection for metal components and parts enclosed in nonventilated cabinets and tool or control boxes, the company explains.

Additionally, the company stresses that the corrosion of complex electronic and electrical equipment is a “serious problem which triggers expensive failures during manufacturing, shipping, storage or field operations”.

“It can be caused by numerous factors such as salt, humidity, moisture, contaminants and more. “Cortex designs and manufactures a wide range of VpCI Emitters to suit [several] applications. “They are installed in small, enclosed areas with little or no ventilation such as electronic cabinets, controller panels, and junction boxes,” the company adds.

It notes that the VpCI Emitters release vapour that forms a thin molecular layer on internal metal surfaces to protect critical, complex and expensive electronic equipment during operation, shipping, or storage. Among the most popular VpCI emitters provided by Cortec are VpCI-105 and VpCI-111.

The VpCI-105 emitters that are powered by VpCI are compact, space-saving, high-tech systems, and provide corrosion protection for metal components and parts in enclosed spaces up to 142 ℓ (5 ft³).

For larger volumes, more than one device can be used. Cortex adds that by using a small device, corrosion can be stopped at any step from manufacturing to final installation.

EcoSonic VpCI-105 has a breathable membrane through which the corrosion inhibitor is released and provides long-term protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, hydrogen sulphide, sulphur dioxide and ammonia, among others.

VpCI-111 Emitters are designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets, or toolboxes up to 312 ℓ (11 ft3).

Both Emitters are very effective in polluted and humid environments and provide continuous protection for up to two years.

“They do not interfere with electrical, optical or mechanical surface properties and are very simple and quick to install and protect during operation and shutdown. “Products are free of nitrites, halogens and phosphates,” Cortec says.

Case Studies

One of Cortec’s clients fabricated two offshore substations in South-East Asia that needed to be transported by vessel to the project location in the Far East.

The journey involved an ocean crossing at elevated humidity and high temperatures, with the potential for tropical storms. The company was concerned about maintaining the integrity of their high value systems on board and approached Cortec Southeast Asia, which had a track record of successfully managing similar contracts in the past.

Cortec Southeast Asia and AOS Offshore executed the turnkey project, including calculating quantities and performing installation of products such as the VpCI-105 and VpCI-111 emitters being used inside junction boxes; Cortec’s VpCI-308 pouches were placed in large enclosures and the VpCI-126 HP UV shrink film being applied for mechanical protection.

Data recording devices were also deployed through the substations to measure temperature, humidity, and G-force during load out, sail away and installation. No delays or corrosion issues occurred, Cortec says, adding that “the client was very satisfied with the results achieved”.

Other typical applications of its products include the packaging and storage of electrical, electronic and marine navigation equipment, as well as use in aerospace electrical controls and electric motors, switching equipment, medical and telecommunications equipment, remote electronics devices and more.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation