Engineering for safety: Cementation Africa’s deeply embedded commitment to risk elimination

The Ivanplats Shaft 2 box cut is shown here prior to construction of the permanent headgear, with careful planning to ensure a safe foundation for future operations

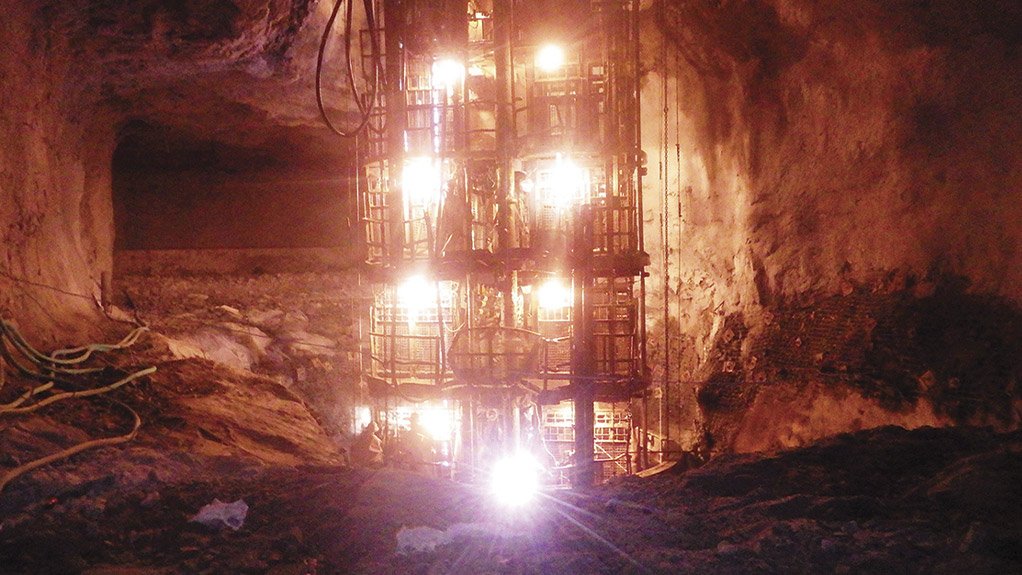

A pre-sink stage in a concrete-lined shaft with services erected, illustrating the structured approach that safeguards workers as infrastructure is progressively installed

The sinking headgear at Palabora Mining Company featured a temporary ventilation discharge arrangement, prioritising safe airflow management during early sinking phases

At Venetia Mine, the pre-sink gantry arrangement included a blast cover and kibble tipping system, designed to protect workers and equipment during early shaft sinking

A sinking stage is shown passing an excavated station underground, with engineered systems in place to ensure stability and the safety of crews at depth

The sinking headgear at Palabora Mining Company incorporates specially designed ventilation pipe support trestles, ensuring safe passage for elephants through the area while protecting both wildlife and workers

At Cementation Africa, safety is not treated as a checklist item, rather it is the very foundation of how the company designs, plans and executes its projects. This mindset is rooted in a philosophy that safe working environments must be engineered, not just managed.

Having evolved beyond compliance-driven approaches, Cementation Africa has embedded safety into its operational DNA. While procedures, training and behavioural programmes play an essential role, the company emphasises that safety starts with design - and it is here that its in-house mine engineering team has made a measurable difference.

“Too often, safety is seen as a system to be followed instead of a culture to be owned,” says Trevor Schultz, Risk Executive at Cementation Africa. “We have taken deliberate steps to make safety intrinsic to the way we engineer our working environments, especially in high-risk activities like shaft sinking and underground development.”

This shift began more than 21 years ago, when the company brought together two operations with different safety systems and cultures. “We recognised that procedures alone don’t save lives - people do,” Schultz says. “And people are empowered to make the right decisions when they work in environments that are designed to eliminate hazards at the source.”

Cementation Africa’s in-house mine engineering team is tasked not only with technical excellence, but with designing solutions that inherently reduce exposure to risk.

“Our design philosophy is simple,” John Goulding, Study Manager in the Mine Engineering department at Cementation Africa , says. “We aim to enable the environment for people to work safely. That means thinking about safety at the concept stage - not as a retrofit once something has gone wrong.”

Backed by an in-depth understanding of the underground mining environment, the mine engineering team brings decades of hard-earned expertise to every project. “There is deep knowledge and practical experience within our team,” says Goulding. “But what sets us apart is how we apply that knowledge, through an innovative mindset and the integration of new technologies that enhance both safety and efficiency.”

From innovative shaft sinking methods to mechanised systems that limit human interaction in hazardous zones, the goal is to create conditions where safe work is the default. “If you engineer the task with safety at its core, you remove reliance on human behaviour as the first line of defence,” Goulding adds. “That is the real power of design - it prevents incidents before they can even occur.”

Cementation Africa has also shifted from a reactive to a proactive safety approach, supported by real-time reporting and a culture of accountability at all levels. “Our teams are encouraged to raise anything that makes them feel unsafe - without fear of blame. These leading indicators allow us to respond before something goes wrong,” Schultz says.

Key to embedding this culture is what the company calls Visible Felt Leadership (VFL) - where safety leadership is demonstrated daily, not just declared. “It is not about enforcing rules from the top down,” Schultz explains. “Rather it is about everyone, from executives to supervisors to frontline crews, actively owning the safety philosophy and leading by example.”

This culture also extends to Cementation Africa’s subcontractors and partners. Every specialist brought onto a project is required to align with the company’s systems and safety expectations. “You can’t have a double standard on safety. If you are working on our site, you follow our way,” Schultz explains.

Ultimately, engineering for safety is not a single initiative but an ongoing commitment – an approach that continues to evolve alongside technology, data and operational experience.

“It is a journey that we take every day, through every project,” Goulding says. “And it starts with smart safe design and engineering.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation