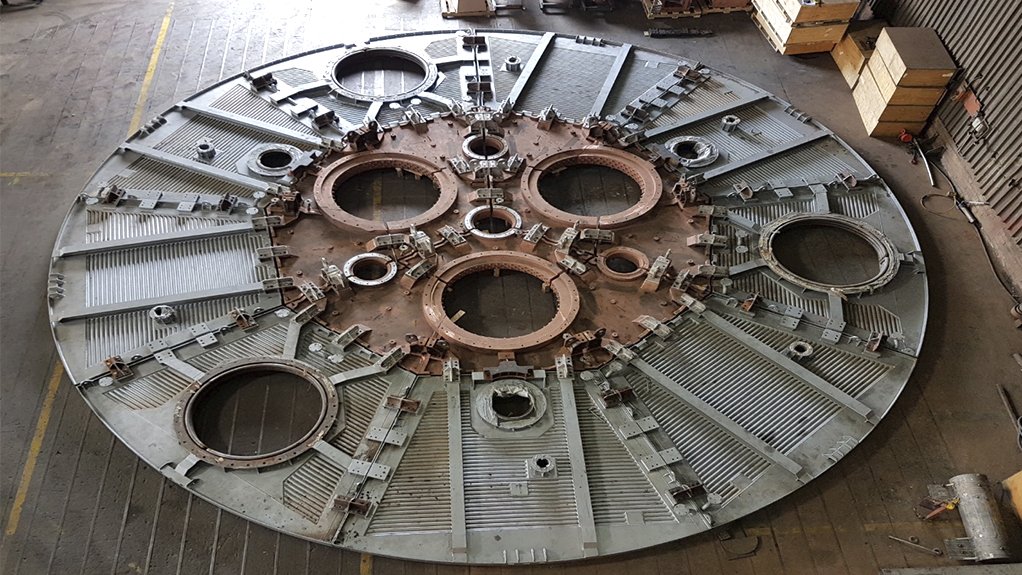

Components supplied to local platinum smelter

DELTA SECTION Thos Begbie hosted some of the major Italian role-players on its premises, in Middelburg, Mpumalanga, to witness work conducted on a previous project

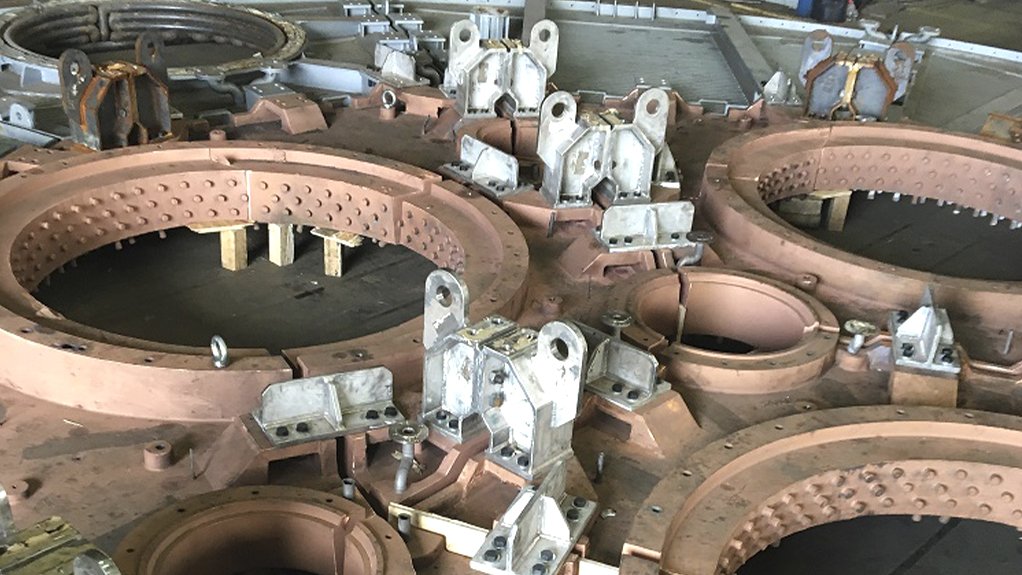

ATTENTION TO DETAIL Thos Begbie conducted rigorous tests and trials for the design house of the project to ensure that the components perform in line with the envisioned design

ESLI BANTJES South Africa will never be in a position to strengthen its economy by shutting itself off from the rest of the world

Foundry and engineering company Thos Begbie has been awarded a major contract to supply 190 t worth of copper pyrometallurgical components to the South African arm of an Italian company for use in a local platinum smelter project.

All components supplied by Thos Begbie must be approved through the client’s head office, in Italy.

The tender was awarded on July 29 and is scheduled to be completed by the end of January next year. The project is under way.

Thos Begbie sales engineer Esli Bantjes explains to Engineering News that a typical furnace design would involve a “bowl” and an energy source for generating heat by burning fossil fuels or by consuming electrical energy.

These are the aspects of the furnace that Thos Begbie is supplying components for and, for this project, the platinum will be melted using electrical energy, he adds.

“Although we are not responsible for the design, we are tasked with the manufacturing of the components to match what the design house has envisioned.”

The melted material will have to be contained within the bowl until it can be tapped off, he explains. This means that the furnace construction consists of a slag taphole to tap off the impurities, as well as a matte taphole to tap off the clean material.

The walls of the furnace are constructed using a specialised copper component that allows for the correct thermal transmittance to ensure that the furnace operates optimally.

Bantjes says this project is the result of a need to optimise furnace operations.

“As technology has evolved and tariffs on electrical consumption have increased, various smelters have been under pressure to implement the necessary changes and improvements to remain competitive in their respective markets.”

The nature of the project necessitates an ongoing relationship with the client, Bantjes adds, explaining that all furnaces are designed and operated with planned routine outages – called routine furnace maintenance shuts – in mind to assess the wear of components.

As such, a campaign life can be established to determine when critical components will have to be replaced.

“We have already been approached by the design house to provide an offer on some critical components. When a routine maintenance shut period has been established, these will be installed.”

He adds that, on the rare occasion where failures, in terms of mechanical damages, reduce the campaign life on the tapholes, they would then have to be manufactured on a breakdown basis.

Since the furnace was designed for the end-user, the design house had to compile a report indicating the critical areas that would need to be changed and under what parameters the furnace would have to operate.

With the positive outcome to this report, the design house was awarded the contract for the design of the entire furnace and the supply of the components.

“We have a long-standing relationship with local platinum smelters, as well as design houses that design the furnaces. As such, we have conducted rigorous tests and trials for the design house of this project to ensure that the components perform in line with the envisioned design.”

South Africa and Italy

Bantjes explains that Thos Begbie has hosted some of the major role-players on its premises, in Middelburg, Mpumalanga, during the process of work conducted on a previous project.

“As such, our group executive has built up not only a professional but also a personal relationship with the Italian client. Personal relationships are of the utmost importance.”

He believes that international business is possible only by establishing close relationships with customers – made all the more possible with modern communication technology.

“In our industry, prospective clients don’t just become another number, but a friendship and partnership is rather established.”

For companies, such as Thos Begbie, and for South Africa to survive, the building of personal relationships is essential so that trust is fostered and integrity is established between nations.

“South Africa will never be in a position to strengthen its economy by shutting itself off from the rest of the world. “To strengthen our economy, we need to provide countries, such as Italy, with services and skills that I believe we have an abundance of,” he adds.

With South Africa situated near the Copperbelt, raw material and minerals are readily available for copper pyrometallurgical components, making Thos Begbie an attractive option for Italian companies requiring furnace components.

“We are flexible enough to assist with tests and trials. We can offer industry expert advice to pyrometallurgical plants, as well as design houses,” Bantjes notes.

He admits that South Africa suffers from some volatile political instabilities that destabilise the local economy, but notes that Thos Begbie works on an international scale using the LME and international currencies to remain transparent in terms of its manufacturing process and what key factors will influence the completion of projects.

“Nonetheless, we have many resources available in South Africa that could assist Italian companies significantly,” Bantjes concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation