Gas can decrease emissions in power generation

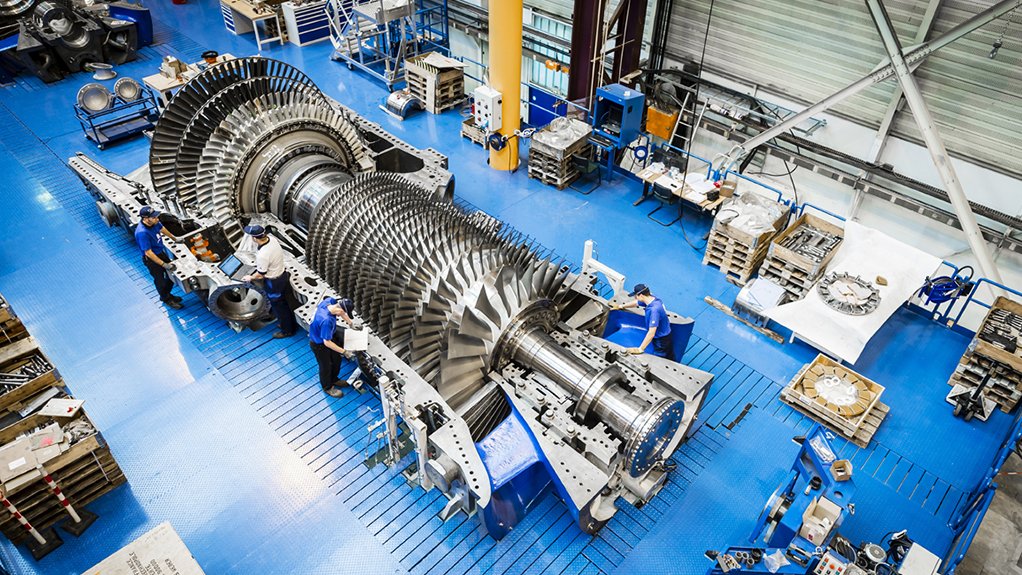

TURNING GAS TO POWER The HA turbine supplied by GE has made significant inroads into the energy sector since its introduction

With power generation being accountable for 41% of current global carbon emissions, which amount to about 33.7 Gt/y of carbon dioxide (CO2), multinational conglomerate General Electric Company (GE) believes that gas can play a vital role in decreasing carbon emissions.

“Gas burns at less than half the CO2 of coal and GE seeks to convert its gas technologies to low or near-zero carbon emissions using hydrogen and carbon capture and sequestration technologies,” says GE Gas Power emerging technologies director Dr Jeffrey Goldmeer.

“Gas power can rapidly change the current trajectory of climate change,” he adds.

Additionally, most energy derived from the combustion of gas offers flexible, dispatchable, affordable and reliable power, which fill the supply or demand gap.

Goldmeer points out that gas can meet more than 90% of energy capacity requirements when needed, and it could run at less capacity, based on variable costs and renewables.

“A gas installation also requires a small physical footprint, which is optimal for dense urban areas with space constraints,” he adds.

Moreover, GE is strengthening its commitment to sustainability by setting the goal of achieving carbon neutrality for its facilities and operations by 2030.

For the decade ahead, GE is targeting the majority of its progress towards the 2030 goal, with absolute reductions of direct emissions and energy use achieved through operational investments, the introduction of smart power sourcing and the elimination of energy waste.

“These investments and improvements are good for the bottom line and for the world, and employees across GE are energised and proud to help with this type of problem solving,” says GE chairperson and CEO Larry Culp.

Key Offering

GE stresses that its key gas offering – the high-efficiency air-cooled (HA) gas turbine combined-cycle power plant – has shown significant results since its inception in 2014.

The company explains that the gas turbine, defined by power combined with efficiency, has been placed on record at more than 64% gas-to-energy conversion efficiency in combined-cycle applications.

The gas turbine has been noted for achieving two world records in energy conversion from gas to energy by delivering 62.22% net combined-cycle efficiency at the EDF Bouchain 50 Hz power plant in northern France, in 2016 and 63.08% gross combined-cycle efficiency at Chubu’s Nishi Nagoya 60 Hz power plant, in Japan, 2018.

A combined-cycle power plant uses a gas turbine and a steam turbine to produce electricity.

GE states that gas turbines could, theoretically, reach 65% efficiency in the near future.

The HA gas turbines deliver the most cost- effective conversion of fuel to electricity and the flexibility to respond quickly to fluctuations in grid demand, helping to pave the way for the greater integration of renewable energy.

The company enthuses that the HA platform is changing the way power is delivered globally and is the world’s largest and the most efficient gas turbine with more than 100 units ordered by 48 customers across 20 countries at the date of this publication.

GE’s second-generation H-class fleet has accumulated more hours of commercial experience.

“We will never stop innovating to make the best even better so that we can continue to provide the world’s most advanced products and technology for customers,” concludes Goldmeer.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation