Generation 2 Reinvented Toilet (G2RT) begins field-test in South Africa

Just over a decade ago, the Bill and Melinda Gates Foundation (BMGF), in partnership with the World Bank, issued a call to “reinvent the toilet”. The BMGF’s Reinvent the Toilet Challenge (RITC) urged innovators around the world to create a new toilet that does not rely on sewage infrastructure, which carries waste through sewers across several kilometres to treatment centres for processing. Sewage infrastructure is both expensive and wasteful of water, especially in a water scarce country like South Africa.

Additional aims for the scheme were to transform waste into useful resources, such as fertilizer, and to limit the cost for use of the appliance to less than R1 a day. The RTTC competition resulted in several winners, with first place going to the California Institute of Technology for a solar-powered toilet that could convert waste into hydrogen and electricity.

Ten years later, associate Professor of mechanical engineering at the Georgia Institute of Technology Dr Shannon Yee, combined the best of the ideas featured in the challenge and packaged them into one new, low-cost toilet that takes the entire process of sewer sanitation and places it inside a toilet the size of a washing machine. The idea of the toilet as an appliance was born.

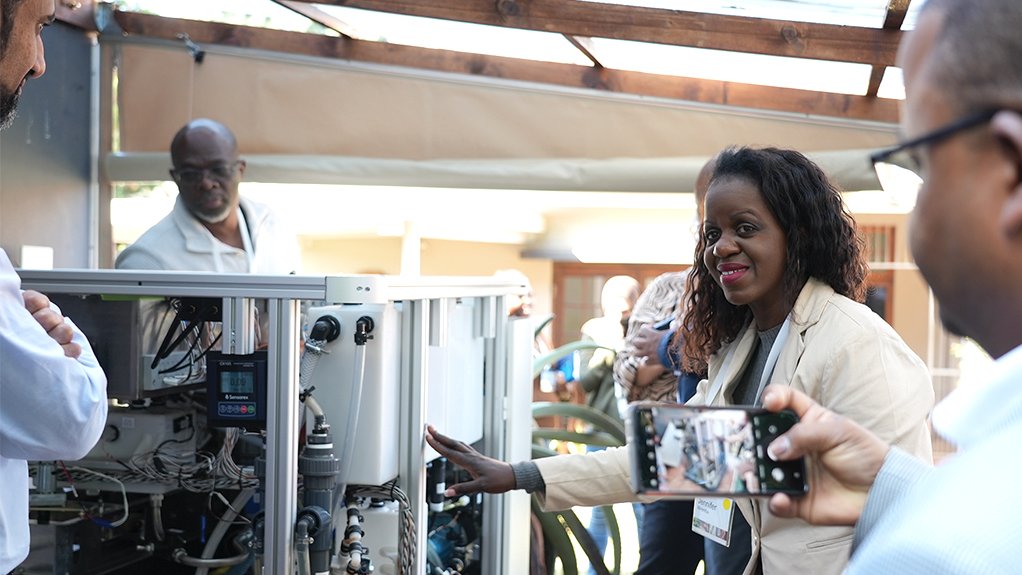

In 2018, the BMGF and the World Health Organisation’s Water, Sanitation & Hygiene programme partnered with South Africa’s Water Research Commission (WRC) and the Department of Science and Innovation to launch the first reinvented commercial demonstration platform to pilot reinvented toilet models in school and community settings. In 2022, the Generation 2 Reinvented Toilet (G2RT) will begin field tests in people’s homes in South Africa, in partnership with the eThekwini municipality, Khanyisa Projects and the University of Kwa-Zulu Natal.

The G2RT demonstration in South Africa is being developed with the aim of providing valuable field experience and flow data that can be used to optimise the current prototype,” the South African Sanitation Technology Enterprise Programme (SASTEP) manager Akin Akinsete tells Engineering News & Mining Weekly.

SASTEP is a national system of innovation platform that seeks to fast-track the adoption of innovative and emerging sanitation technologies in South Africa through fostering local manufacturing and commercialisation. The core strategy of the programme is to support and empower sanitation technology and commercial partners.

“The plan is to have two more iterations of the G2RT before we have something that is ready for the market. Georgia Tech is also testing the appliance in France and India, so it covers a broad range of global expected uses of the toilet,” he says.

South Africa has a long history with the reinvented toilet. Since 2011, the country has been making valuable contributions to the development of the G2RT with the hope that it will eventually be manufactured locally.

“Since we’ve contributed to the testing, we should not become an importer of the technology, but rather transition from testing to local manufacturing so that we can reap the benefit of the effort we’ve contributed to the initiative,” notes Akinsete.

The G2RT will also create commercial opportunities across the sanitation value chain.

Licence agreements between the inter-national technology partners and local manufacturers have been negotiated and some of these have subsequently commenced local manufacturing. Akinsete is hopeful that those contracts will contribute to quality manufacturing jobs.

“These are not going to be run-of-the-mill jobs that we see currently with the construction of toilets. These will be high quality manufacturing jobs that will be created once the project reaches full scale and full adoption,” he points out.

There will also be opportunities for SMMEs to provide appliance maintenance, since the G2RT is more like transitioning sanitation into an appliance, “so where one currently has technicians to fix appliances such as washing machines or dishwashers, the G2RT will also require local technicians to provide these maintenance services”, he explains.

The initiative will create jobs for manufacturing as well as downstream after-sales

services, which opens the way for job opportunities.

While it is not currently known whether the G2RT will be fully manufactured in South Africa, or just assembled here, Akinsete says SASTEP’s focus is to optimise the current prototype to reduce the price so it will be affordable for the local market. The G2RT is currently priced at $450 (about R8 000).

While the reinvented toilet is more technologically complicated than a standard toilet, the user experience will be similar to that of a regular toilet. Akinsete explains that the appliance is “basically a miniaturised treatment system” comprising ultrafiltration and a reverse osmosis (RO) unit as well as a drying operational unit. The system offers several benefits, particularly with regard to water and energy efficiency.

Since the waste will be treated in situ, the energy requirement is more efficient than that of a traditional waste disposal system. In a traditional system, once the toilet is flushed, the waste and several liters of water move through a pipe to a pumping station and then to a centralised wastewater treatment plant where the water is recovered and the waste is processed and treated.

The G2RT is much more energy efficient since the waste and water are collected and processed in the appliance, while the water is treated and can be used again to flush the toilet.

The G2RT also promotes resource circularity.

“Because South Africa is a water-stressed country, being able to use a reduced amount of water for flushing is going to help tremendously,” says Akinsete.

He explains that the waste is subjected to ultrafiltration and RO, and is then dried into a pasteurised disc that is free of pathogens. This carbon material can then be disposed of in the garden as a fertilizer, or in the general household waste.

The G2RT will also assist in making sanitation a strong empowerment tool.

“The idea of a sanitation system being an appliance offers more options and choice to the end-user, especially for indigent communities, who until now have had to be satisfied with whatever the State prescribes.”

While a system such as this one will require behavioural changes, Akinsete believes that the benefits, such as promoting climate resilience and resource recovery and reuse, will encourage people to adapt more easily to this new technology.

Further, government policies will enable people to make decisions about sanitation. The Department of Water and Sanitation (DWS) is already leading an initiative to develop the Water and Sanitation Master Plan, which is a plan intended to guide the water sector with investment planning for the development of water resources and the delivery of water and sanitation services beyond 2030.

The Department of Trade, Industry and Competition is also working on a water and sanitation industry master plan, to which the WRC is contributing.

“The policies seek to create water and sanitation industrialisation to promote localisation and the local manufacture of innovative water efficient technologies, such as the G2RT. The biggest obstacle is to encourage private sector involvement,” he says.

The provision of sanitation services is perceived as a public good, so many commercial entities are reluctant to move into this sector. There have been challenges in getting commercial partners to buy into the vision of the reinvented toilet as an appliance.

“However, there are people who see the opportunity for investment. Transitioning to the idea of sanitation as an appliance could change the perception of the sector, where it is not dependent on government.

“We hope that through the work we are doing at SASTEP, we are able to elevate the current sanitation sector to something that is appealing and attractive for businesses and entrepreneurs, to bring in new sources of funding, and innovative operational and revenue models that can transform the sector into one that not only creates new jobs, but develops into something that can contribute to the GDP of South Africa,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation