Grindex Stainless Steel Mega Inox Proves Long-Term Reliability at Copperbelt Mine

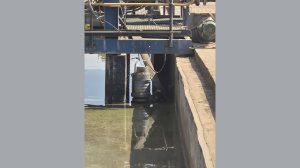

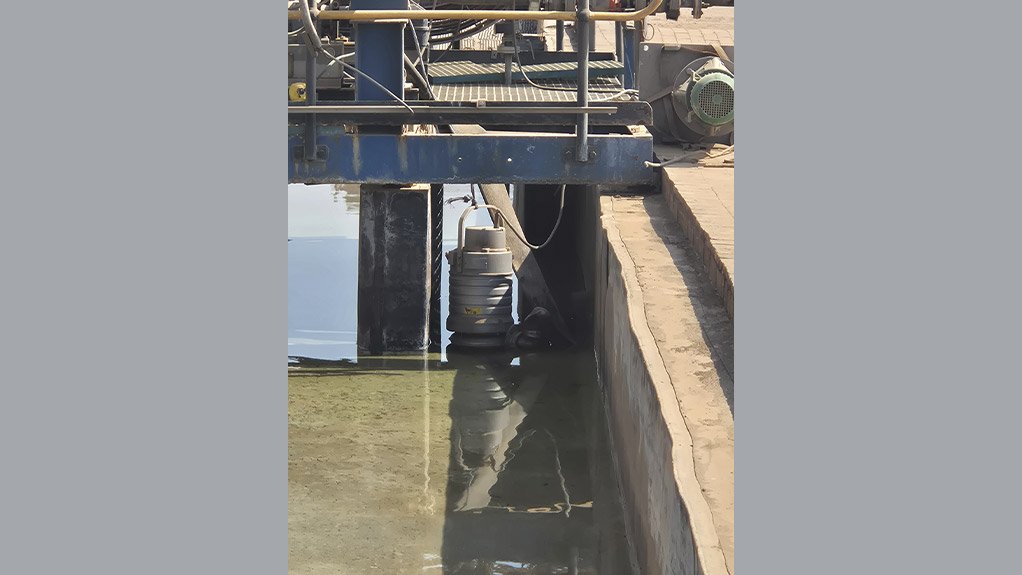

Integrated Pump Technology’s Grindex Mega INOX pump in action at a major Zambian mining site, delivering reliable dewatering from the tailings dam to the process plant

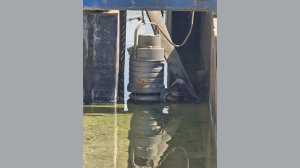

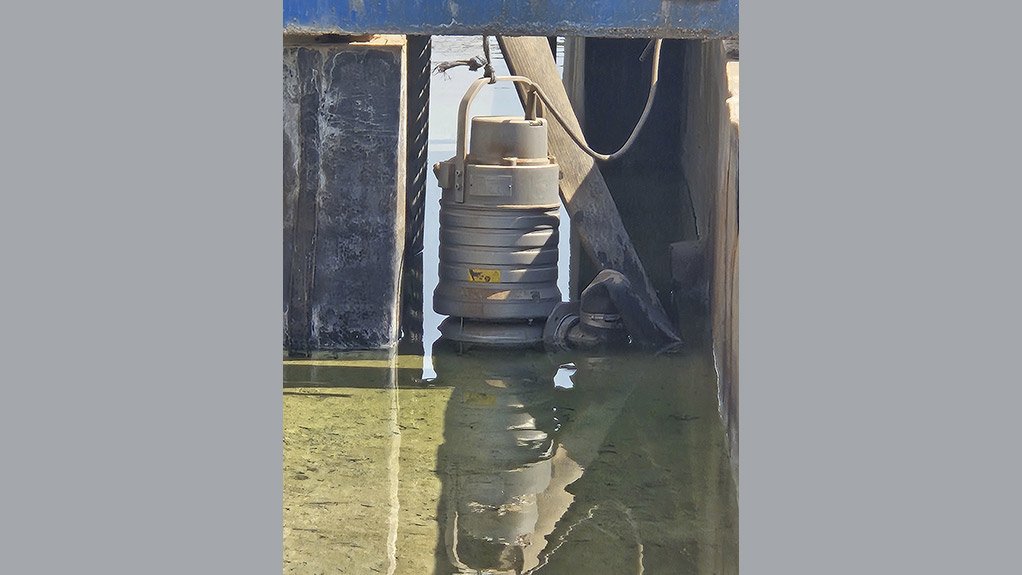

The 85kW Grindex Mega INOX pump has operated continuously for nearly a year, meeting the mine’s high head and flow requirements with ease

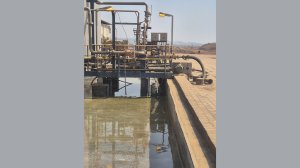

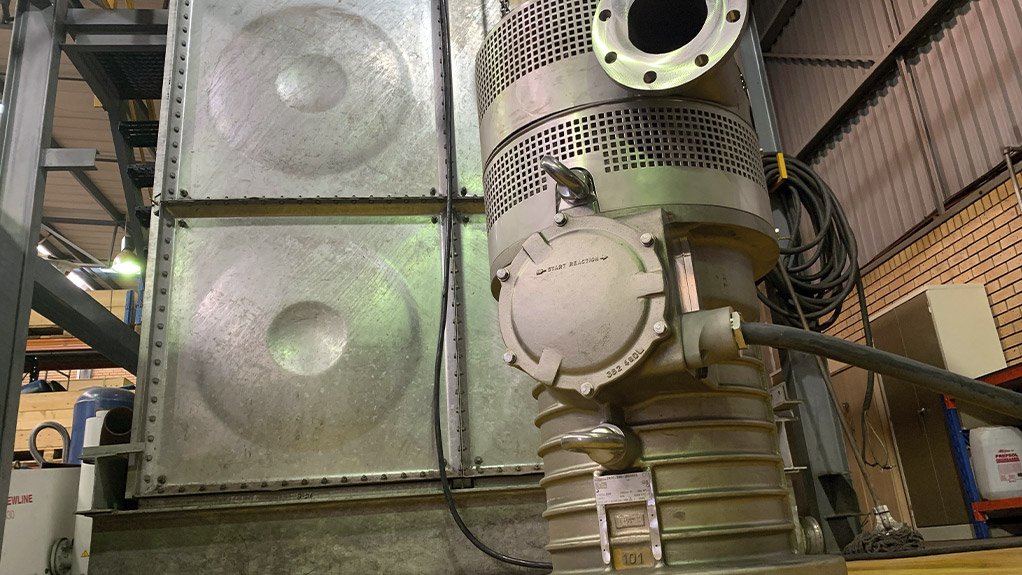

Backed by local distributor IES, Integrated Pump Technology ensured rapid deployment of the Grindex Mega INOX pump thanks to strategic stockholding in Zambia

A trusted partnership: Integrated Pump Technology and IES provide on-the-ground technical support and spares for seamless pump operation

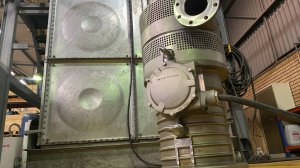

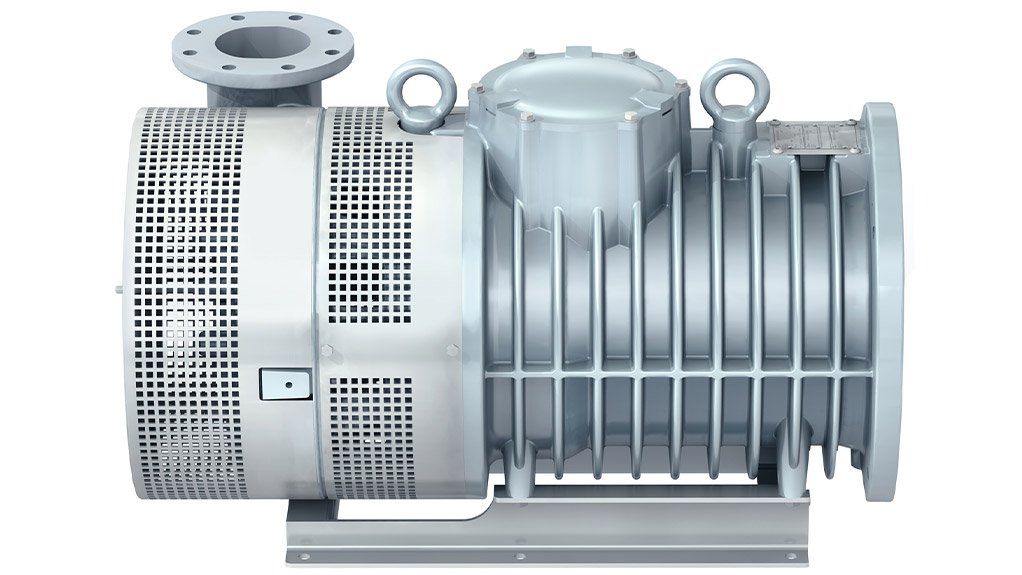

Built for tough conditions, the Grindex Mega INOX pump handles aggressive, high-chloride water with confidence and efficiency

The Grindex Mega INOX pump’s high efficiency motor and advanced hydraulics deliver dependable performance with low energy consumption

This article has been supplied.

Integrated Pump Technology, in collaboration with its local distributor IES, stepped in to provide a reliable dewatering solution at a major mining operation on Zambia’s Copperbelt.

Almost a year later, the 85kW Grindex Mega INOX stainless steel dewatering pump continues to operate successfully, transferring water from the tailings dam back to the process plant, says Alfred Kelsey, Sales Manager at Integrated Pump Technology.

“This was the first unit of its kind to be installed at the site and the customer was extremely pleased with its performance during the three month trial,” says Kelsey. “They valued the confidence we had in the pump, which allowed us to offer a 12 month warranty. Equally important was the fact that we could provide local support through our distribution partner, IES - not something all pump suppliers in the region can offer.”

Thanks to the strong partnership between Integrated Pump Technology and IES, strategic stockholding in Zambia ensured that the Grindex Mega INOX pump was available ex-stock and could be deployed without delay, he adds. The unit is tasked with pumping water at a rate of 60 litres per second at a head of approximately 80 metres.

Kelsey notes that the Copperbelt region hosts some of the wettest mines globally and with mining activity on the rise the demand for Grindex dewatering pumps is gaining solid momentum.

“In particular, our units in the power range of 10kW, 18kW, 37kW and 90kW are especially popular,” he explains. “These models offer a combination of high performance, robust design and long service life - making them ideal for demanding mining applications.”

He highlights that Grindex pumps are engineered for high head and high flow applications and are built with features that set them apart in tough conditions. These include durable stainless steel or cast iron construction, advanced motor protection and built-in air valves that allow the pumps to run dry without damage.

The pumps also incorporate smart cooling designs and heavy-duty mechanical seals to ensure reliability in highly abrasive and corrosive environments, such as open pit and underground dewatering and tailings management.

“The Mega INOX, for example, can handle aggressive water with high chloride content which is common in tailings dams,” says Kelsey. “It is equipped with a high efficiency motor and hydraulics to ensure minimal energy consumption while delivering high performance.”

Another advantage is the ease of serviceability. “Grindex pumps are designed for quick maintenance with minimal downtime and many components are interchangeable across models, which simplifies logistics for mines,” he adds.

Combined with the local technical expertise and readily available spares and units through IES in Zambia, customers are assured of fast turnaround times and minimal disruption to operations. “This holistic support structure is key to maintaining uptime in environments where every minute counts,” Kelsey concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation