Hydra Arc eyeing mining industry, international markets

Hydra Arc engineering manager Matthew Alfonso speaks to Creamer Media about the company's unique service. Video & Editing: Creamer Media's Nicholas Boyd.

Although there are many benefits when partnering with steel fabricator Hydra Arc, engineering manager Matthew Alfonso says the company’s “unique service” remains core to its management philosophy, as this means that “all layers of management are required at the coal face to support employees, remove obstacles and develop solutions to the work being executed”.

“We have seen how this key philosophy has underpinned the benefit of using Hydra Arc, and has not only led to our success, but the success of projects for our clients,” he comments.

Referencing a recent example, Hydra Arc management was able to identify inefficiencies in the handling of welding gasses, which resulted in project delays and excess manpower across a multiple story boiler. This approach, Alfonso says, meant that over the course of six months, Hydra Arc was able to design, test and implement a solution resulting in reduction of gas movement of over 35%.

“This saving was not only beneficial to Hydra Arc, but the fiscal benefits were shared with the client. A solution to a problem that would have never been identified without our key philosophy,” Alfonso enthuses.

Additionally, he notes that another benefit of working with the Hydra Arc group is the company’s “sheer capacity to handle the work”.

“Our facilities are a fundamental competitive advantage element for Hydra Arc, as our chairman, José Maciel, has always stood firm on the idea that without the infrastructure we cannot perform. As a result, we have been lucky to have a chairman that is willing to invest on a scale surpassing anything seen in the local industry, by building one of the largest fabrication facilities in the southern hemisphere,” he elaborates.

This facility includes, among other features, 75 000 m2 undercover fabrication space, cranage to lift 1 500 t in a single lift and fully automated post weld heat treatment ovens, of which the largest is over 9 m wide, 9 m high and 70 m long.

These facilities have allowed the company to build flagship projects, including building the first ever modular plant assembly project in the southern hemisphere, as well as the largest vessel fabrication project manufactured by a South African company, consisting of five propylene storage bullets and a depropaniser stabilisation drum.

Having executed countless shutdowns, turnarounds, and projects, Hydra Arc has, over the years, accumulated a vast data base of skilled artisans from around the world. This, Alfonso explains, ensures that the benefit to a client is that “no matter how large or technically difficult your project is, Hydra Arc will have access to the right people”.

While Hydra Arc has and continues to use other country nationals where necessary, the company views this as an opportunity to make a difference.

“We seized this opportunity by creating one of the largest training and development centres for welding, boiler making and mechanical fitters in South Africa,” Alfonso states.

Known as Hillside Artisan Training Academy, the centre trains over 1 000 artisans each year, and has steadily grown to becoming one of the best artisan schools, focusing on a competency-based training that benefits the entire industry.

This feeds into the common understanding within the industry that “the driving element in all maintenance is not the failure of a given item, but the consequence of that failure”.

With this in mind, Alfonso explains that Hydra Arc’s most important service applications are the maintenance and expansions which it conducts on plants and equipment within the mining, petrochemical and power industries.

This alludes to primarily being on sites where the consequences of equipment failure could have substantial impact on the country’s economy and security.

“It is therefore a service which Hydra Arc has placed a substantial focus on, with continual growth, technological advancement, and training ensuring that we are the best in the industry and never realise the consequences of bad maintenance within these sectors,” Alfonso states.

LOOKING AHEAD

While the world has started to see a gradual increase in economic activity since the fourth quarter of 2021, Alfonso comments that Hydra Arc has experienced “significantly more frugal” customers compared to in the past.

This, he remarks, ultimately cascades down the supply chain and “has had a significant impact on the competitive landscape”, and he therefore encourages companies of substantial scale “to be more adaptable to ensure they remain competitive, whilst still maintaining substantially greater overheads to compete on mega projects”.

In this sense, he notes that Hydra Arc, specifically, will “place a major focus over the next 12 months on diversification” in customers, locations and the industry.

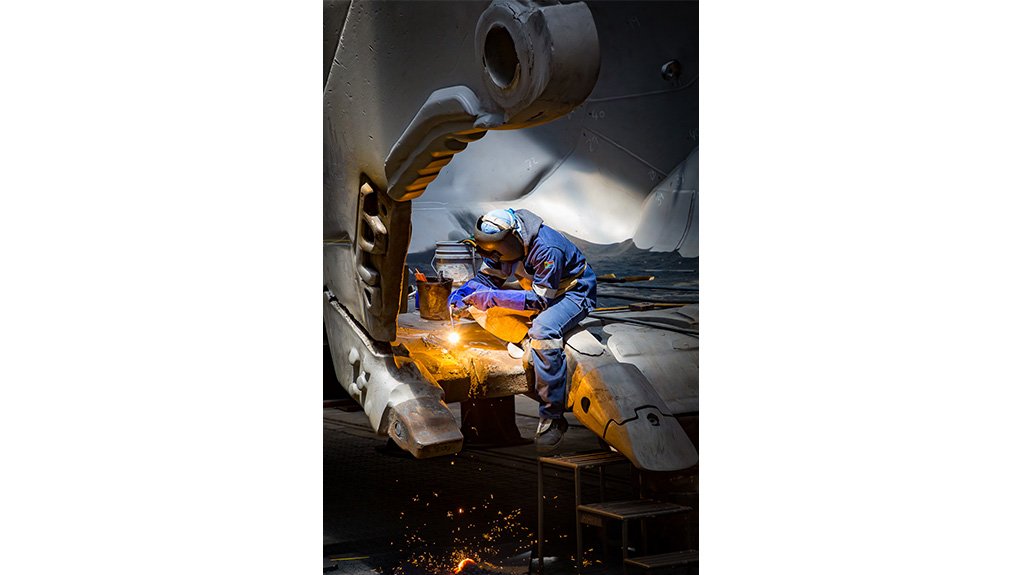

“Mining is one such industry that Hydra Arc is focused on, and although we have manufactured and refurbished multiple dragline and shovel buckets, dragline shoes, and tanks within the mining industry, there is a major focus within our business on further entrenching ourselves by using our momentous facilities and core skills,” Alfonso explains.

“We truly believe that we have the ability to add true value to the mining industry,” he adds, noting that the company has also set its sights on international expansion.

Hydra Arc is currently in negotiations to conduct plant maintenance in the Kingdom of Saudi Arabia.

This plant is said to be one of the largest in the world and would be a significant win on Hydra Arc’s journey to international expansion.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation