IDC, KfW funding green hydrogen, green ammonia project in solar-rich Northern Cape

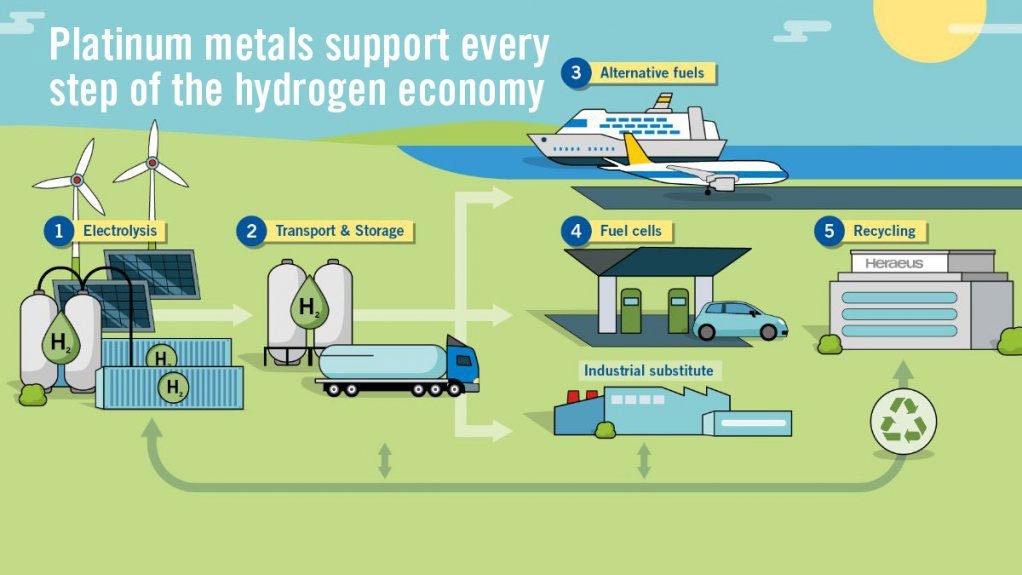

Platinum group metals support every step of the vitally necessary energy transition.

Photo by Heraeus Precious Metals

JOHANNESBURG (miningweekly.com) – Project development funding for the Prieska Power Reserve Project is being partly sourced from the German Kreditanstalt für Wiederaufbau (KfW), South Africa’s State-owned Industrial Development Corporation (IDC), which has also approved development funding to the project, has outlined in an advertisement.

The green-hydrogen-linked Prieska project, which is located outside Prieska in the Northern Cape, aims to produce 80 000 t of green ammonia a year. It is owned by Mahlako Energy Fund, a women-owned empowerment consortium, and Central Energy Corporation (Cenec), a Bloemfontein-based emission energy company that designs and manages solar and wind energy plants. Initiated by Mahlako and Cenec, the project is on privately owned farms of about 1 900 ha, which are sites earmarked for renewable-energy generation.

While these generation sites are located outside Prieska, a town on the south bank of the Orange river, the green ammonia chemical processing will be located within the industrial area in Prieska, on land owned by the Siyathemba local municipality.

The 14 500 t/y green hydrogen content will be produced by a 120 MW electrolyser, and renewable-energy sources, made up of 180 MWp of solar photovoltaic (PV) power and 136 MWp of wind power, will power the electrolyser. The project includes a 45 MW battery storage system to ensure continuous 24-hour operation.

Mining Weekly can report that although green hydrogen generation and platinum group metals (PGMs) invariably go hand-in-glove and although South Africa hosts most of the world’s PGMs, no explicit reference is made by the IDC to the use of PGM-based proton exchange membrane (PEM) electrolysers and fuel cells.

But the latest edition of Hydrogen Fuel News puts it this way: "The Northern Cape’s known for its sprawling semi-arid vistas, underground mineral treasures, and sunlight that feels like free energy. Prieska itself grew up around copper deposits and farms along the Orange river. Now, with solar PV, wind turbines, and PEM electrolysers, the region is making a clean break – from digging in the dirt to driving green hydrogen and ammonia production. It’s a smart play: harness top-tier renewable resources while jumpstarting local industry."

The publication describes the PEM electrolysers as the "true stars" that leverage electrolysis to provide hydrogen production and oxygen from desalinated water in a manner that is perfect for ammonia production.

It says that local procurement is being targeted for everything from construction materials to day-to-day operations,which will strengthen regional supply chains.

It reports that skills partnerships with nearby technical colleges are being established to equip young talent for careers in hydrogen infrastructure.

Moreover the project's Strategic Infrastructure Project status speeds up permitting and unlocks more public and private investment for items ranging from component manufacturing to export logistics.

"We expect ripple effects as equipment suppliers, transport operators, and chemical offtakers set up shop, turning Prieska into a budding hydrogen infrastructure cluster. The world’s in a sprint for industrial decarbonisation and low-carbon fuels. Green ammonia – often hailed as the most cost-effective carrier for long-distance hydrogen – is forecast to hit multi-billion-dollar markets by 2030. South Africa’s edge comes from exceptional solar and wind resources that drive down production costs; a strategic spot near rail lines and ports for smooth exports to Europe and Asia; and existing mining and chemical hubs ready to pivot toward green feedstocks," Hydrogen Fuel News outlines.

Off-take agreements are reportedly already in the pipeline with agricultural and chemical firms and if timelines hold, the first clean ammonia cargoes could set sail by 2028, benchmarking new green hydrogen hubs across Africa and the Middle East.

"If you’re keeping tabs on the future of green hydrogen, Prieska is your bellwether. It shows how public finance, local empowerment, and global partners can join forces to produce a zero-emission export commodity," the publication adds.

PEM'S GLOBAL RECOGNITION

Interestingly, PEM’s global recognition has been emphasised once again by the World Platinum Investment Council LinkedIn note, which points out that the US-based clean energy technology firm Ohmium International has opted for PEM, with this observation from Ohmium CEO Markus Tacke: “Our latest Lotus Mark 3 PEM electrolyser system is transforming the economics of green hydrogen production.”

In addition. Plug Power president and CEO Andy Marsh has pointed out to Engineering News & Mining Weekly in a Zoom interview that PEM technology is at the heart of everything that Plug Power, a US Nasdaq-listed company, does. Plug Power has been a prime mover in the US’s platinum catalysed green hydrogen and fuel cell economy and Marsh points out that the adoption by US business of this planet-friendly way of doing things is because it pays to do so.

Plug Power built and operates the US’s largest liquid green hydrogen plant, a 15-t-a-day liquid hydrogen plant that uses 40 MW of Plug’s platinum- and iridium-catalysed electrolysers.

Plug Power is involved with more than 80 000 forklift trucks being powered by the 250 hydrogen fuelling stations it has built. Between Walmart and Amazon, there are about 150 sites that use Plug Power’s PEM technology to operate around the clock and with the help of Plug Power’s technology, these companies talk about moving 8% to 10% more pallets an hour, while also being users of clean energy that mitigates against climate change.

PEM electrolysers generate the green hydrogen by splitting water, including sea water, into hydrogen and oxygen.

Then fuel cells, which are also catalysed by PGMs, convert the green hydrogen into green electricity for mobility or stationary uses.

Moreover, the flexibility provided by liquid organic hydrogen carrier (LOHC) technology, which is being developed by the South Africa-linked German company Hydrogeneous, provides the oily skin for green hydrogen to be transported, stored and traded in the same way as oil and gas is currently. Very fortuitously, LOHC ensures that green hydrogen can be transported and stored using existing liquid fuel infrastructure, including ships, tanks and trucks. By offering a versatile and adaptable solution for hydrogen transport and storage, LOHC is said to unlock the full potential of hydrogen as a clean and sustainable energy source.

“Africa's green hydrogen journey has just begun. By fostering collaboration between government entities, universities, and the private sector, we can unlock the immense potential of this clean energy source. Imagine a future where African ports become green hydrogen hubs, powering ships and industries with clean fuel. It's an achievable dream, but only through collaborative action,” Engineering Centre of Excellence head Tauqeer Ahmed has pointed out.

SOLAR POWER

Not that long ago, solar power was regarded as too expensive to implement, despite Africa’s abundance of sunshine, but now cheap solar is powering the energy boom of the entire continent of Africa, with major renewables growth in South Africa.

As with solar in the past, in some circles green hydrogen is still seen as needing to come steeply down the cost curve.

In this regard, it can be pointed out that effort, not unlike that applied to solar, is under way in places that include the province of Hunan, a home of green revolution, as well as elsewhere in China.

A direct South African link with Hunan is through the company SANY, which provides heavy industry equipment including from its considerable South African base. This base is clearly visible to motorists on the way to Gauteng’s East Rand.

It can be pointed out that Hunan is also the place where electrified vehicle mobility as well as green railway transport is being advanced.

PRIESKA FUNDING

Regarding the Prieska project, it can be pointed out that part funder KfW, which was formed in 1948 after the Second World War, is committed to improving economic, social and environmental living conditions across the globe while the IDC, established in 1940 through an Act of Parliament, is fully owned by the government of South Africa.

This project, the IDC reports, plans to take advantage of South Africa's competitive advantage in the renewable-energy market and use South Africa’s abundant solar and wind resources to produce green hydrogen and ammonia.

By doing so, the IDC adds that it will contribute “substantially to local and national socioeconomic development objectives” and create 400 jobs on reaching commercial stage.

Green hydrogen is an energy carrier that is produced using renewable electricity and water in an electrolyser.

Market applications for green hydrogen include the production of green chemicals such as green ammonia, mobility solutions, sustainable aviation fuel, marine bunker fuel and the decarbonisation of 'hard to abate' sectors of the economy. Examples of these sectors are green steel production, cement manufacturing and petrochemical production.

In developed markets, the green hydrogen economy has created significant job opportunities – a development that South Africa aims to replicate, the IDC points out in the advertisement that does not reveal the extent or terms of the funding being provided by itself and KfW.

"The fine print on IDC and KfW’s back-end financing is under wraps, but it was officially sealed at the Africa Green Hydrogen Summit and rides on South Africa’s Strategic Infrastructure Project status," Hydrogen Fuel News points out.

In addition to the Prieska project, green hydrogen- and green ammonia-related projects include the the Hive green ammonia export project at Nelson Mandela Bay in the Eastern Cape, Keren Energy green development near Vanrhynsdorp, in the Western Cape, and a related fuel cell and electrolyser component manufacturing facility project in Gauteng is Isondo Precious Metals.

Keren Energy CEO George van Rensburg has reported that the front-end engineering design (FEED) study and bankable financial model for the project have been completed, with most of the permits for the project in place. The project site has also been secured through a long-term lease.

The Keren project team aims to reach financial close by the end of this year, with production anticipated to start in the first half of 2028. The total investment required for the project’s full development is around R1-billion. In the first phase of production, Keren Energy aims to produce about 800 t of green hydrogen a year.

REQUEST FOR PROPOSALS

Earlier this year, a request for proposal (RFP) process was launched to inform the FEED study for a fully integrated green hydrogen project at the East London Industrial Development Zone (ELIDZ), in the Eastern Cape.

Green Hydrogen Solutions (GHS), through its project company GHS Green Hydrogen ELIDZ, is seeking input from leading equipment suppliers for the project. Distinguished by its closed-loop system design, the project will use desalinated seawater to produce high-purity green hydrogen for industrial and commercial customers.

The project will encompass the complete green hydrogen value chain. Proven desalination technology will be used to treat seawater to produce water suitable for electrolysis, while surplus water will be supplied to commercial customers.

Electrolysers (10 MW) powered by renewable-energy sources will be used to split desalinated water into green hydrogen and oxygen. Infrastructure will be installed to compress, store and deliver the green hydrogen reliably to identified offtakers.

This RFP invites potential suppliers of key technologies and equipment to provide information that will inform the FEED study. Areas of interest include seawater desalination systems, electrolyser technologies, hydrogen compression solutions, hydrogen storage systems, hydrogen distribution equipment and related balance-of-plant components and control systems.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation