Imported solution combats pipe corrosion

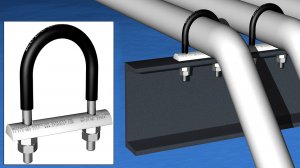

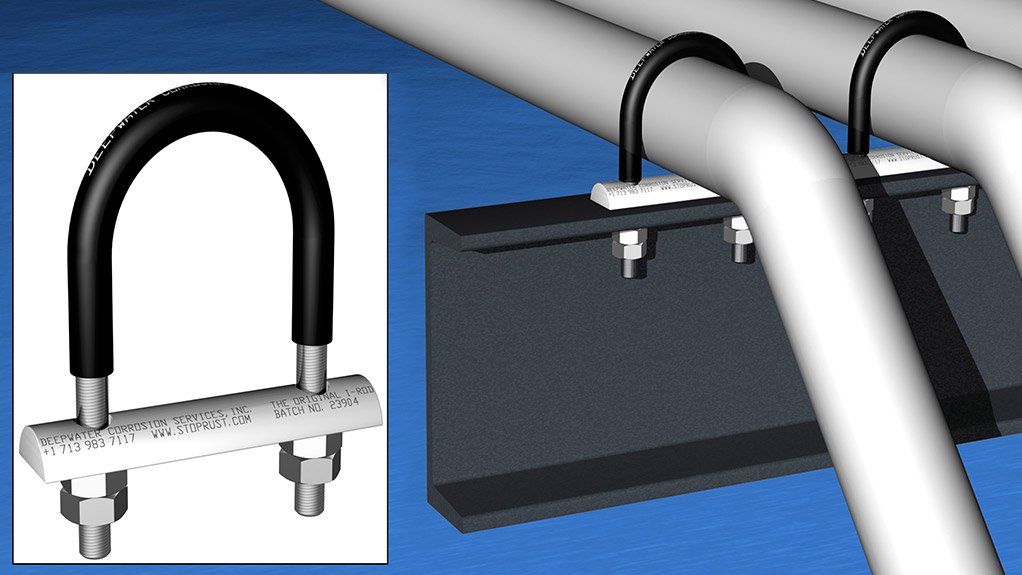

THE IROD & NUBOLT The Irod and Nubolt system limits galvanic corrosion by negating metal-to-metal contact and by allowing trapped water to be drained

Photo by Total Heating Solutions

South Africa-based corrosion control, heat treatment and bolt torque equipment supplier Total Heating Solutions acquired the distribution rights for US-based cathodic protection systems design and manufacturing company Deepwater’s Nubolt and Irod pipe support system in February this year.

Total Heating Solutions business development manager Iain Cockin notes that the insulated Nubolt U-bolt prevents metal-to-metal contact between pipes and support structures in refining and power generation applications, while the shape of the thermoplastic I-rod allows water to drain at the area where the support structure and pipe meet.

“One of the main reasons for corrosion at power stations and refineries is water leaks, which commonly occur where the pipe support joins the pipe. Water is collected in little pockets, created by the pipe support, which leads to galvanic corrosion.

“Galvanic corrosion is caused by moisture and contact between two different metals, and can result in the protective coating of the pipe and the support structure breaking down,” he explains.

The Nubolt and I-rod are available as an inclusive solution or can be bought separately.

Cockin highlights that while Total Heating Solutions has yet to secure any supply contracts for the system, it has been successfully adopted in the US, particu- larly since it was found that gal- vanic corrosion was the cause of several refinery explosions, the most recent being the explosion of US-based independent petroleum refiner Silver Eagle Refining’s Utah refinery in November 2009.

He adds that he successfully supplied the solution to refineries and power stations in Vietnam and Malaysia from 2007 until his return to South Africa from Asia in 2013.

Cockin asserts that while the I-rod appears to be a simple device, none of Deepwater’s competitors have successfully reproduced the material content, which can support the weight of large pipes typically found at refineries and power stations.

Total Heating Solutions is also the local supplier for US-based corrosion monitoring company Rohrback Cosasco Systems. “The company has been the leader in corrosion monitoring since 1950,” Cockin tells Engineering News.

Further, he notes that Total Heating Solutions launched the Microcor high-speed, internal-corrosion monitoring device in November last year.

“The new Microcor system monitors corrosion that occurs in a pipe, which is an important safety element that is often overlooked by refineries and power stations. The system provides a real-time corrosion report of what is happening inside a pipe.

“Using the Microcor, a user places a probe or coupon into pipe access points. The information from the Microcor is fully retrievable online, limiting downtime, as refineries and power stations do not need to shut down to check for pipe corrosion,” Cockin explains.

He highlights that the system can also monitor chemical inhibition programmes, a process whereby chemicals are injected directly into the pipe to prevent corrosion and kill bacteria.

“Previously, refinery and power station personnel would have to wait several days, or even months, to determine the effectiveness of a chemical inhibition programme. With the Microcor online system, they can place a probe a few metres ahead of the injected chemicals, which will provide a computer read out, plotting the corrosion rate of the chemical inhibition programme.

“In this way, the system can provide the best chemical inhibition input from the temperature analysis and the chemicals being injected,” explains Cockin.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation