Improved welding helps local company alleviate corrosion

REFINED HARD-FACING WELDING As the demand and quantity of components requiring hard-facing increased, Thos Begbie begun looking at alternative methods of conducting specialised welding

Foundry and engineering company Thos Begbie has developed and improved its welding processes to weld dissimilar metals to copper to mitigate the effects of erosion, particularly chemical corrosion, in the local industry.

“It is commonly known that copper is an ideal material to be used in the pyrometallurgical industry, owing to its thermal transmitting properties. Unfortunately, copper is also relatively malleable and soft, making it susceptible to corrosion and erosion in a harsh furnace environment,” says Thos Begbie sales engineer Esli Bantjes.

One particular process involves the use of hard facing overlay. This has been used in various aspects of the engineering industry for crusher machines and various mining operations, and is a metalworking process where a more resistant alloy is applied to a base metal, such as copper

Thos Begbie has further developed the use of hard facing on copper components to create a fused bond between dissimilar metals, which would be the copper component and another alloy. This is done for the protection of copper furnace components, where tribology, corrosion and heat up to 400 ºC are common, he explains

He mentions that, among the different alloys which can be welded to copper components, two remain a “favourite” in the smelting industry. This includes Inconel and Hastelloy.

He elaborates with the explanation that Thos Begbie has perfected the process of deep penetration fusion of an alloy to the copper component to a near metallurgical bond. Similar processes only use a single layer of hard facing on top of a copper surface, with incomplete fusion, which leads to separation from the copper component while in operation.

“All smelters, regardless of the process, have a similar goal in mind, which is to extend the life of the furnace. There have been various efforts to achieve this and, among other methods, using hard facing overlay in critical wear areas has been extremely successful.”

He adds that while the company has offered these hard-facing welding services for more than three decades, the company has perfected the process in the last few years.

“Thos Begbie is geared up with the best available technology, equipment and experience in producing the copper components for the pyrometallurgical industry’s smelters globally. Owing to the mechanical abrasion- and erosion-resistant properties of copper, we started looking at other industries which would benefit.”

Locally, this included Thos Begbie approaching various heavy earthmoving machinery companies to apply this layer of hard facing to bin trucks, trench diggers and any equipment exposed to excessive wear.

Further, the company has upgraded its process to use automated robots to perform the welding.

While all the processes developed still remain the same in terms of standards, a significant difference is the use of artificial intelligence to allow for more consistent welding and provide a safer working environment for operators.

“We have relied on artisanal skills and attention to detail, which no machine can replace. As the demand and quantity of components requiring hard-facing have increased, however, we had no other option but to look at alternative methods of conducting this specialised welding.”

Consequently, a welding robot, developed and manufactured in Switzerland, was installed and commissioned at the company’s foundry at the beginning of last year. Bantjes argues that this signalled a new era for artisans, as training was required to facilitate the transition to more modern engineering.

Projects

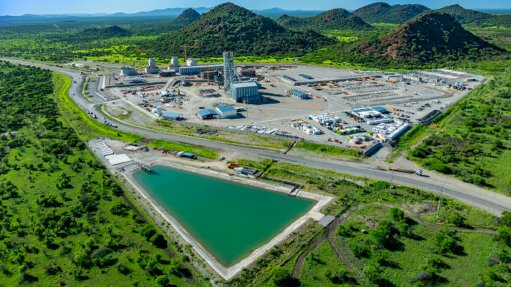

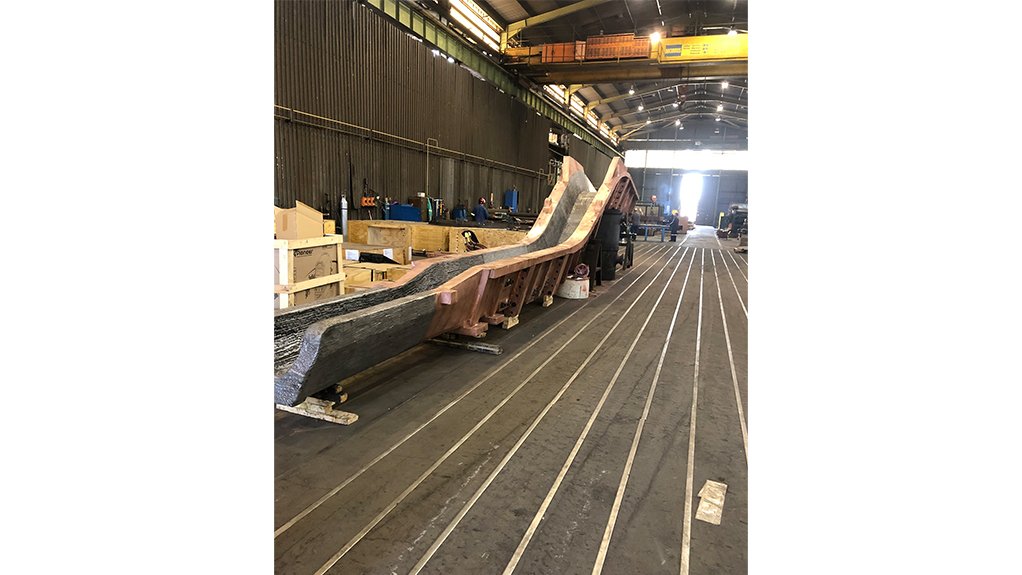

Thos Begbie has conducted a significant overlay weld project, which required the application of hard facing to a Zambian copper smelter’s launders.

Bantjes describes that the process of smelting and reducing copper matte or metals results in the separation of the matte and the waste, or slag. The lower-density slag has to be tapped off with copper launders, or runners, into ladles through a tapping hole.

The copper launder is exposed to temperatures as high as 1 500 ºC, while the melting point of copper is around 1 084 ºC. This will burn through the launder without the effective cooling and preventing of burn-through, owing to friction or abrasion “wash” of the fast-flowing gravity-fed protective layers.

Bantjes explains that the company spent six months manufacturing these components and used about 600 kg of welding wire. This is one of the largest overlay projects that Thos Begbie, or any of its competitors, has successfully completed, he adds.

One challenge of the project was the weight of the components, as some of them weighed as much as 5 000 kg. This made moving components into position to weld different contours of the casting onto the components more difficult.

Bantjes concludes that the company is also involved in a similar project locally, which is still in the developmental trial stage. The developmental work involves applying hard facing to the furnace wall components of a platinum smelter.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation