Investments to help increase recycling in EU

RECYCLING ACHIEVEMENT The initiatives and investments by Tetra Pak are set to boost the European Union’s ability to recycle beverage cartons which includes the non-fibre protective layers of polyethylene and aluminium, residues remaining after paper mills have recovered the paper fibres

Photo by Tetra Pak

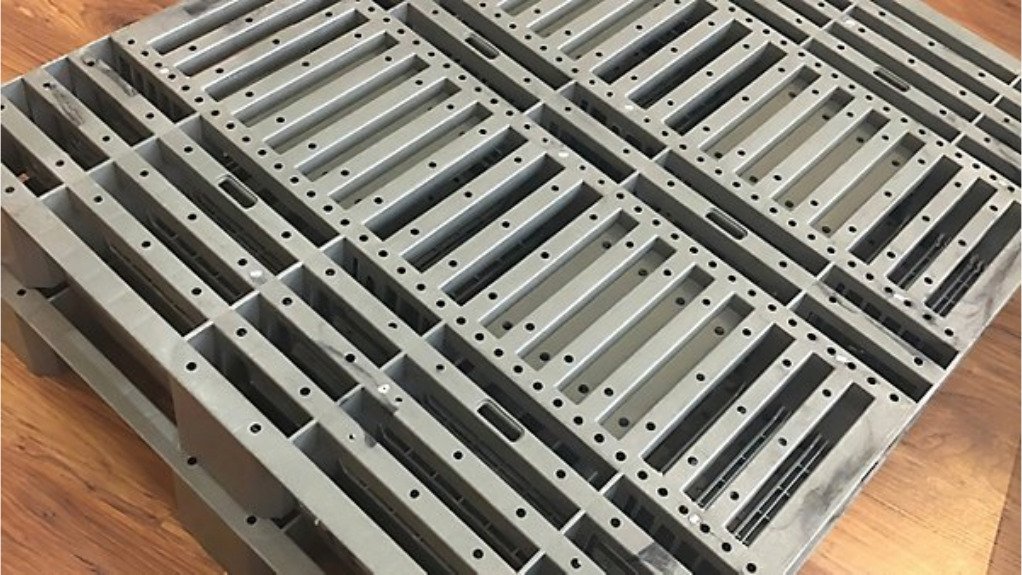

MATERIAL VERSATILITY PolyAl has unique thermal properties for increased productivity in the plastic transformation process, ultimately transforming into a range of everyday items

Photo by Tetra Pak

In February 2024, food processing and packaging solutions company Tetra Pak announced several strategic investments designed to improve the recycling capacity for carton packages in the European Union (EU).

The move supports the goals of the proposed EU packaging and packaging waste regulation by ensuring that all packaging components are recycled and valuable raw materials are kept in circulation for longer, and showcasing the pivotal role of recycling in the green transition of the food packaging sector.

In 2023, Tetra Pak invested nearly €40-million to accelerate beverage carton recycling worldwide and it plans on increasing this further over the coming years to achieve greater material circularity.

The initiatives and investments are set to boost the EU’s ability to recycle beverage cartons, which include the non-fibre protective layers of polyethylene and aluminium (polyAl), a residue remaining after paper mills have recovered the paper fibres.

The company aims to achieve this by either opening new collaborations or by strengthening the capabilities of established recyclers to turn all materials from post-consumer cartons into new high-quality resources and goods.

These will add to the existing and well-established recycling infrastructure in the EU, where beverage cartons are recycled in 20 specialised paper mills, with polyAl being processed by seven facilities, and a further six being under development.

Major Investments

A few of these major investments made in 2023 included Tetra Pak and Swedish polymer company Axjo Group starting a feasibility study to build a new recycling line for polyAl that will accommodate volumes from Sweden, Denmark and Norway.

This was fostered by a joint investment of up to €24-million and featured yearly recycling capacity of 10 000 t. This facility will recycle and incorporate polyAl into injection-moulded plastic products made by Axjo.

In Spain, Tetra Pak co-invested €2-million with industrial recycling company Trans Sabater and expanded the agreement to increase the installed polyAl capacity from 3 000 t/y to 10 000 t/y.

This valuable secondary raw material has unique thermal properties for increased productivity in plastic transformation processes and is exempt from the plastic tax, as it is a 100% recycled material of post-consumer origin.

Additionally, Trans Sabater’s patented mechanical recycling technology improves the quality of the pellets compared with traditional processes. Potential end markets for recycled polyAl include logistics, packaging, retail and gardening.

Tetra Pak also forged another collaboration in Spain with post-consumer carton recyclers Alier, which will help the company become an integrated player – one that is able to process all materials from used beverage cartons.

By making use of mechanical recycling, the polyAl will be transformed into high-quality pellets, suitable for a variety of end markets. The ambition is to recycle over 15 000 t/y of polyAl by 2025.

Tetra Pak has also invested €1-million on the development of an efficient process to convert polyAl into widely applicable plastics, at Recon Polymers’ polyAl recycling plant, in a bid to increase the capacity to at least 8 000 t/y.

This will not only improve the efficiency of the process but specifically advance material circularity across France, Belgium and the Netherlands.

The material’s versatility means it can be transformed into a range of everyday items including reusable pallets, interiors and large-format three-dimensional printed objects.

“For us, this goes beyond industry investment. It’s part of the transformation towards a circular economy and an investment in the future of our planet,” Tetra Pak sustainability operations VP Markus Pfanner commented.

He added that these innovative collaborations, “at the intersection of human ingenuity, technology and finance”, demonstrate the value of beverage cartons within sustainable food systems.

He explains that the beverage cartons are recyclable, and are recycled wherever the necessary collection, sorting and recycling infrastructure is in place, at scale. He notes that “naturally” expanding this infrastructure is a priority for Tetra Pak.

“Projects such as these ensure that consumers can continue to safely access food, and that once they have done so, those cartons can be recycled, keeping quality resources in the loop and reducing the use of virgin content,” Pfanner concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation