Lack of contractual commitments hindering solar-geyser manufacturing growth

The current economic climate and a lack of mid- to long-term contractual agreements from the Department of Energy (DoE) have slowed plant expansion and capacity increases by local solar water heater (SWH) manufacturers.

Local manufacturer Satchwell Controls Appliance Controls division key account manager André Nieuwoudt notes that, while there are perceptions that local manufacturers are unable to meet the demand of the DoE’s SWH roll-out, he asserts that there are enough local manufacturers to deliver. However, many companies are unwilling to invest in plant capacity increases without assurances from the DoE that demand will sustain SWH production.

Satchwell, a division of electromechanical company Actom and a member of the Solar Water Heating Manufacturers Cluster of South Africa (SWH-Mancosa), which represents about 90% of local SWH manufacturers, is one of nine local manufacturers that form part of the social component of the DoE’s larger national solar-geyser roll-out programme.

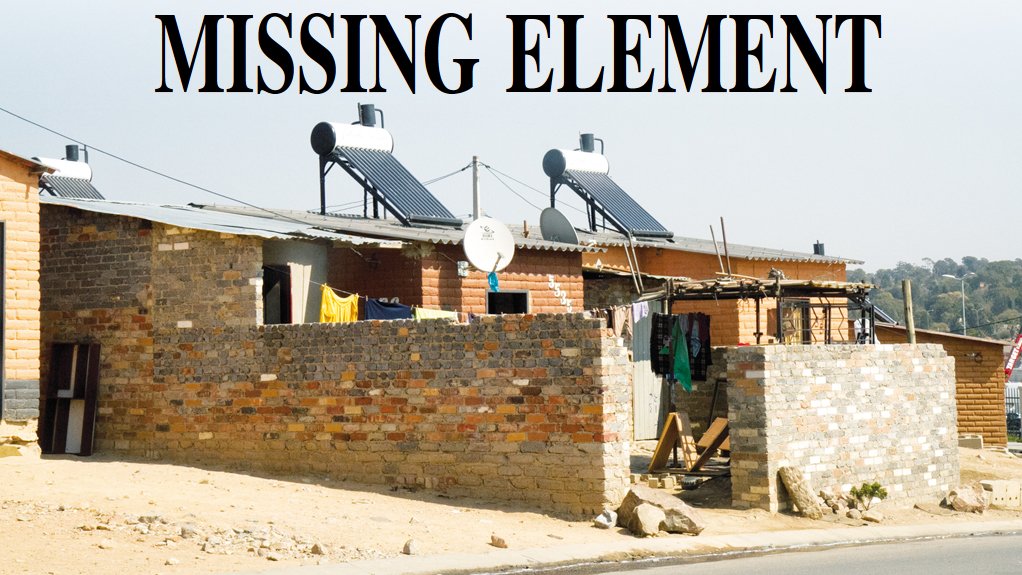

The social component of the programme, which entails the supply and warehousing of low-pressure SWH systems that will be installed in reconstruction and development programme (RDP) low-cost houses, opened for requests for bids in December 2015. The preferred bidders were announced in February last year and the supply agreements were signed the following month.

The plan envisages the procurement of 1.25-million systems by 2019, raising the total installed base to 1.75-million, with a number of systems having been installed under the rebate scheme previously administered by State-owned power utility Eskom.

Systems supplied, installed and maintained through the social programme will be installed largely on a free-issue basis, but provision has been made for such systems to be provided on a partially subsidised basis.

The larger national roll-out also includes insurance and voluntary components. Under the insurance component, a subsidy will be provided to enable insurers to promote the replacement of conventional electric geysers with compliant SWH systems, while South Africans who would like to participate under the voluntary arrangement will be able to contact a national call centre for a similarly subsidised installation.

Currently, only the social component of the programme is active, which is being rolled out in accordance with the provisions of the Preferential Procurement Policy Framework Act (PPPFA) and the PPPFA Regulations, which include a 70% stipulated minimum threshold for local content on the main components – the storage tanks and solar collectors – of the systems.

Nieuwoudt points out that the 70% local- content commitment applies only to government spend and that many local companies have selected to stock imported products to ensure their sustainability. Companies that have secured contracts with government can sustain local production numbers, he adds.

“The industry as a whole sells more SWHs to private projects and developments,” he says, adding that cheaper imported products are more attractive for price-sensitive consumers. However, he adds that “local businesses need to remain profitable, so they generally stock locally manufactured and imported products”.

GOVERNMENT WILL

During her Budget Vote speech in May this year, Energy Minister Mmamoloko Kubayi highlighted the department’s national SWH programme as a prime example of intergovernmental cooperation, which is being received from the departments of Human Settlements, Small Business Development, Higher Education and Training and, Trade and Industry, as well as provincial governments and their respective municipalities.

“We are alive to concerns from communities about the challenges related to the previous implementation model and we are very careful not to repeat those mistakes,” she said.

In her speech, Kubayi highlighted that the DoE, which allocated a R411-million budget for the programme, intended to continue with the roll-out of SWHs and noted that the department had procured about 60 000 baseline systems from local manufacturers.

“I must reassure those South Africans that the provision of modern thermal energy carriers and finding solutions to their energy needs will be my pre- occupation as Energy Minister,” she said.

COMPLIANCE AND TESTING

Meanwhile, successful bidders on the DoE’s social programme are required to provide verification of the local content, with the South African Bureau of Standards (SABS) serving as the independent verification agency.

Geyser manufacturers are required to receive a SANS 151 test report, which certifies that geyser products are safe for household use. SWH manufacturers are also required to receive a SANS 1307 solar-performance test for their systems, which ensures the safety of a particular solar configuration and also measures its performance.

SWH-Mancosa media liaison officer Theuns van Aardt tells Engineering News that one of the most significant challenges the industry is facing is the requisite testing needed to receive South African National Accreditation System (Sanas) approval from the SABS.

“We are having issues with the testing of our products but it is a sensitive issue that might need further intervention in time. Currently, compliance testing has limited functionality and the local industry is struggling to get products through testing to keep up to date with the various compliance standards,” he asserts.

To mitigate the challenge, the SWH-Mancosa and the Plumbing Industry Registration Board are seeking out alternative testing facilities to receive Sanas accreditation for solar systems and products, some of which have been out of date for two years, Van Aardt asserts.

He highlights that products are also randomly retested under the SABS mark scheme for compliance; however, this has also stalled, resulting in a significant backlog, placing many local manufacturers at risk.

Van Aardt adds that the cost of testing a product has also risen significantly in the past 18 months from about R57 000 to R125 000, further compounding the financial burdens of local manufacturers wanting to work on government projects.

However, he notes that the introduction of the SANS 10400 XA construction standard in 2011, which states that all new buildings must generate at least 50% of their water-heating capabilities from renewable sources, such as a solar water geyser, has provided increased demand for SWH systems.

Further, while the initial investment cost is still high, payback periods for SWH systems have declined significantly, with an expected return on investment on a 150 ℓ system dropping from more than five years to about 3.5 years.

“Consumers are able to save about 25% on their electricity bill by installing a solar geyser, which is becoming increasingly relevant, owing to Eskom’s increased tariffs. We have a massive opportunity to grow the local manufacturing capacity of this industry, which has always provided great opportunities for job creation and access to export markets,” says Van Aardt.

The local SWH industry is valued at about R300-million, produces 30 000 locally manu- factured products and provides about 2 200 direct employment opportunities, he adds.

CHANGING HANDS

Eskom’s rebate programme was launched in 2008 to help mitigate energy system constraints by installing a million solar geysers in homes across the country by 2013. However, the programme managed to roll out only about 424 790 solar geysers by the time the programme was handed over to the DoE in January 2015.

Eskom informed SWH stakeholders in December 2014 that a handover process was under way and that the DoE would manage the future implementation and funding of the programme.

The State-owned utility withdrew from the programme to focus on its main business of supplying electricity; however, it did accept rebate claims on high-pressure SWH systems installed before and up to April 30, 2015.

In February 2015, Engineering News reported that the SWH programme under Eskom, which offered rebates of between R5 000 and R12 000, depending on the size of the geyser, fell short of its one-million SWH quota, owing to a number of reasons. These included Eskom’s lengthy procurement process; a misalignment with the targeted electricity demand reductions, owing to focus having been placed on SWH installations in low electricity-consumption areas; and unreliable verification of the number and location of installed systems, owing to a lack of systematic reporting and independent verification.

Further, poor-quality installations, a lack of maintenance obligations by the suppliers and poor workmanship, which resulted in SWHs being dysfunctional, also contributed to the challenges faced by the ambitious programme.

Also in February 2015, the DoE released a statement notifying stakeholders of updates to transitional arrangements after the programme had been handed over to the DoE in January by Eskom. The DoE said the rebate scheme would be reintroduced and that subsidies would be offered with considerations regarding local content.

However, the DoE informed Parliament the following month that the programme had been “frozen”, owing to the poor quality of installation and unreliable verification of the number and location of the installed systems.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation