Magway secures its first big (Fortune 500) customer

The Magway system

Rupert Cruise

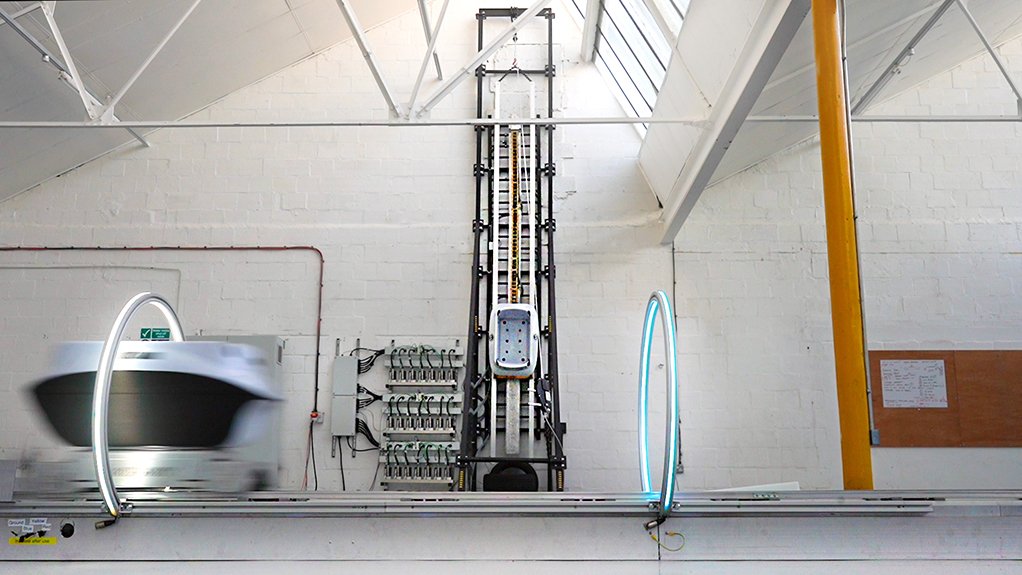

At work in the Magway workshop in London

The Magway system at work

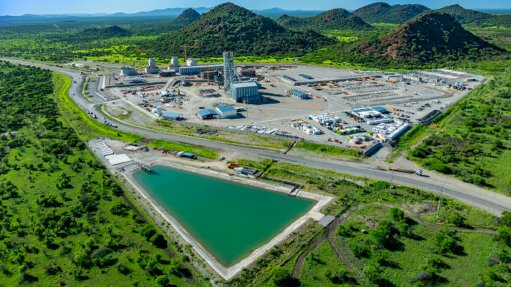

What the Magway system will look like in a distribution centre

UK-based sustainable logistics company Magway has secured its first commercial customer in the form of a large Fortune 500 multinational group, says CEO and founder – and South African – Rupert Cruise.

Magway is a zero-emission delivery system (when powered by renewable energy), consisting of carriages running at speed, on a track, on a network of overground or underground pipes that are around one meter in diameter.

The network can span a distance ranging from a few hundred meters to tens of kilometres. The carriages can move horizontally or vertically, even inside buildings, owing to its small diameter, explains Cruise.

Apart from very low energy use compared with other transport methods, including electric vehicles, the system is also green as it replaces delivery vehicles in the middle-mile of the logistics chain. This means it also reduces traffic congestion.

Magway’s technology adopts electric linear motors to power the carriages. Deliveries can be timed to the second, with a tracking system allowing the customer and the service provider to monitor where deliveries are located within the system, while also reporting on the general health of the goods.

For the 49-year-old Cruise, Magway’s first big customer is a timely coup as his company moves from startup to scaleup.

Cruise graduated in 1994 with a BSc in electrical engineering from the University of the Witwatersrand (Wits); his final-year project investigated the control of linear induction motors for deep-level mining hoists.

He filed his first patents on linear motors in 1998.

Cruise worked on a number of South African mine-related projects, before starting an MBA at Oxford University in 2000 on the back of the gold price sliding to $280/oz.

He settled in London in 2001, starting a company called Texchange. In 2015, this became Linear Motion Technologies (LMT), with Magway spinning out of LMT in 2017.

Projects on Cruise’s CV include designing linear synchronous motor systems for a US Navy aircraft carrier, working in partnership with Chris Lines, a master’s student at Wits.

Cruise and Lines also assisted Hyperloop One (later to become Virgin Hyperloop One) on the analysis of the design of the company’s linear motors and eddy current brakes.

Today, Cruise, his wife and children live in North West London.

Materials Mover

Magway’s first customer visited its facility in September 2020, says Cruise.

The Magway building houses a 65 m loop track, demonstrating the viability of the technology, while it also provides the engineering team the opportunity to continuously refine the system.

“Once the client saw the test track, we spent the next six months negotiating a mutual collaboration agreement. We then kickstarted the project in March 2021,” says Cruise.

“Over a nine-month period, we went from concept to full-scale design for a Magway system to move materials within this company’s industry.

“Unfortunately we can’t say who they are, only that they operate outside our initial core focus, which is to decarbonise e-commerce.”

Cruise tells Engineering News Online that Magway is “helping the customer to transform its business, which has been operating in the same manner for the past 150 years, to become more sustainable”.

“These guys have a whole division looking at how tech can be used to make their business more sustainable.”

“What we are doing is much the same as in 1995, but a lot has also changed,” notes Cruise. “The technology has shrunk in size and come down in price significantly. Add to that more processing power and smarter data communication and all of a sudden you have a very flexible, very green delivery network.”

Cruise explains that Magway will not construct the transport system for its first client.

“We’ll do the design and the software, but someone else will manufacture and build the system. For our first commercial small plant we’ll operate it jointly.”

Cruise adds that Magway has had “phenomenal growth” over the past year.

“We grew the team by 200%. We have 32 fulltime people working here. We should end the year with 100 people if we continue on the same growth path.”

Cruise is hopeful that Magway’s first system will be up and running in 2023, if the global supply chain crunch doesn’t create any further or unforeseen delays.

Other projects Magway is working on include a delivery system for a new smart city region, as well as a system connecting two warehouses within the same UK logistics group.

“This company has two warehouses – one a regional consolidation centre and the other a distribution centre,” says Cruise.

“These warehouses are 350 m apart. There are currently about 100 truck journeys a day between the warehouses, on a 2 km one-way system.

“Magway is ideally suited to move the goods between these warehouses, eliminating a number of touch points along the way.

“The alternative is building one big consolidated warehouse, but Magway is definitely the less expensive, more efficient option.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation