New manifold series launched and locally produced

SY SERIES The new SY series offer further air savings, as a result of driving bigger cylinders with reduced cycle times without the need to use larger solenoid valves

ERNST SMITH Proof pressure or maximum applied pressure has been tested to ensure safety for operators or machinery on the production line

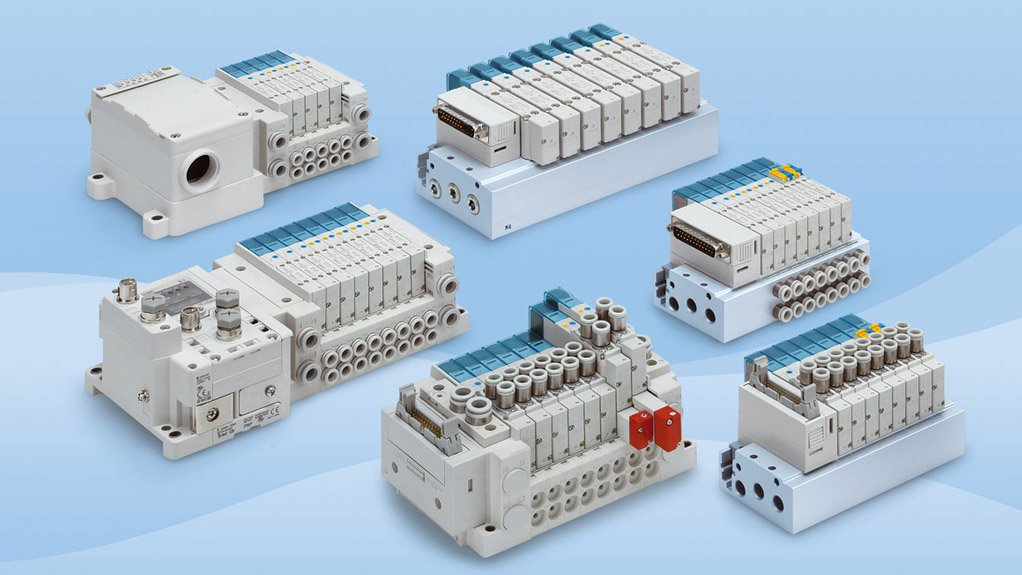

Along with the start of local production later this year, global pneumatics technologies manufacturer SMC Pneumatics has boosted its local range with the redesigning of its SY series of valve manifolds.

SMC Pneumatics product manager Ernst Smith notes that the new series is available in three sizes – the SY3000, SY5000 and SY7000. He adds that the design, which is 29% smaller than the previous version, allows for greater flexibility, increased flow rates and greater overall economical operation.

The valves in the new SY series offer further air savings, as a result of driving bigger cylinders with reduced cycle times without the need to use larger, more expensive solenoid valves, he adds.

The valves are available in either rubber or unique metal seal versions, with the metal seal version being particularly suitable for higher operating frequencies and extended life-span performance, boasting switching cycles of up to 200-million cycles, Smith explains.

He notes that the SY series of pneumatic valves is available in a rubber-sealed spool and a metal- sealed spool, providing life cycles of 70-million and 200-million respectively. He adds that a 10 bar manifold is also available on request.

He adds that the SY series is available in a standalone valve or can be integrated into a manifold comprising up to 32 solenoid coils.

The series being a Japanese design, Smith notes that users can be assured that the proof pressure or maximum applied pressure has been tested well above these limits to ensure safety for operators or machinery on the production line.

Further, the metal seal version enables the spool to literally glide on a very thin layer of air, resulting in very high switching frequencies, low wear and a larger switching cycle count.

“Since the valve series is the actual interface between the pneumatic actuators on the pro-duction line and the customer’s controlling programmable logic controller, they are used in a spectrum of industries [that have] pneumatic actuators as a source of mechanical motion.”

These industries include the packaging, automotive, chemicals, textile, food and bever-age, mining, semiconductor, machine tool, pulp and paper, agriculture and amusement industries.

Smith, however, draws attention to the fact that, as the food and beverage industry is the largest in South Africa, it remains important to the Midrand-based company, as it retains several customers in this sector, as well as in the equally important automotive industry.

While the SY series of manifolds can be used with typical pressures used in everyday appli- cations ranging from a –1 bar vacuum to 7 bar pressure, Smith adds that the manifolds also conform to ingress protection (IP) standards of enclosures around electronic equipment with an IP67 rating, higher than the industry norm of IP65.

For companies that do not need compre-hensive environmental protection, Smith notes, an IP40 lower specified solution is sufficient.

“Customers should not have to pay more for protection of the manifold if the environment it is used in does not require it or if the manifold gets mounted in an enclosure anyway,” he states.

Smith adds that, with integrated Web server functionality, increased flow rates, dual redun-dancy safety shut-off and reduced weight and size, SMC can respond to industry requests as they arise.

“Whenever a new request is received from the market, we have procedures in place to log this onto an international database where they are collected and considered for future development,” he notes.

New Facility

SMC Pneumatics’ new production facility, in Midrand, remains a welcome addition to oper-ations in South Africa. The facility, which was opened last month, allows for shorter delivery times and the availability of nonstandard stock items and will boost operations in Africa.

Smith tells Engineering News that the facility, which will be in full operation next month, will initially focus on cylinder production with bore sizes ranging from 6 mm to 300 mm in diameter, as well as manifold assemblies and air preparation combination sets.

“SMC’s local production facilities will also be used to produce standard stock items to bridge stock gaps often caused by bigger, unexpected customer orders. Customers will enjoy the benefit of availability of such items without the long lead times. Further, when presented with an old, odd cylinder that has failed after years of use, SMC has the resources . . . to assist in getting these customers’ machines up and running again,” he adds.

According to Smith, the typical hardwired SY-manifold SY5000, with six to eight valves, will roughly cost less than R10 000 and will be assembled and tested at the local facilities.

“Upon receipt of the works order, all components required to produce the SY manifold are col- lected in one basket – from differ-ent local stock bin locations – and sent to the manifold assembly area. “The entire manifold is then assembled using special electrical torque screwdrivers, from where it goes to the manifold test bench, where it needs to pass a stringent test procedure,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation