New technology uses sound to recover 92% of platinum from hydrogen fuel cell stacks

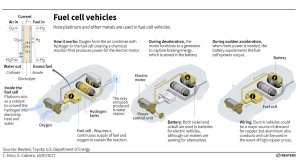

How platinum is used in fuel cell electric vehicles.

A glimse inside Hydrogen South Africa.

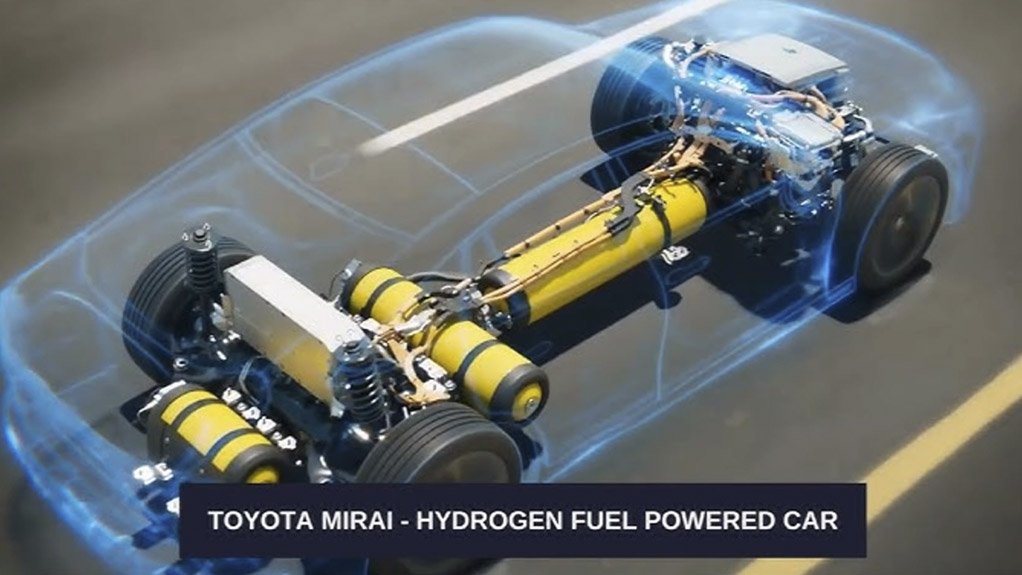

Mobility insight provided by Lhyfe.

JOHANNESBURG (miningweekly.com) – New technology, which uses sound to recover 92% of platinum from hydrogen fuel cell stacks, is emerging from Johnson Matthey, a company which, interestingly, has a long-standing South African presence.

Earlier this year, the company founded in 1817, reported in a White Paper that the growing need for platinum group metals (PGMs) cannot be met through conventional below-surface mining alone.

Now, it has put its money where its mouth is though research and development that uses what journalist Angie Bergenson described in the latest edition of Hydrogen Fuel News as “acoustic cavitation – that’s basically bubbles formed by sound waves – to gently, but effectively, break apart the membrane structure”.

The technology has the potential to recover a lot more PGM material, augment mining in a far cleaner way, and may also work for water electrolyser recycling, another key piece of the green hydrogen puzzle.

The membrane electrode assembly (MEA) material disassembled by the technology is the central part of platinum-based proton exchange membrane (PEM) green hydrogen fuel cells that provide emission-free mobile and stationary energy arguably with the greatest holism and effectiveness.

A fuel cell stack consists of many single cells stacked up so that the platinum-based cathode of one cell is electrically connected to the anode of the adjacent cell. In that way, exactly the same current passes through each of the cells.

The World Platinum Investment Council this week saw fit to draw attention on LinkedIn to this new technology, which is seen as being poised to contribute significantly to the circular economy and to ensure that recycling makes a greater contribution to the availability of PGMs, some of them far scarcer than others.

This innovation, in which the UK’s University of Leicester features prominently, is described as marking “a big step toward closing the loop in platinum recovery and pushing us closer to a future where clean tech gets smarter, greener, and a whole lot more sustainable”.

Interestingly from a local viewpoint is that if you drive down Henderson road in Germiston South, you will come across the name Johnson Matthey Pty, which is part of “an ambition to be a world leader in sustainable technology solutions, transforming energy and reducing carbon emissions, for a cleaner, brighter future”, through collaboration with customers, partners, academic research institutions, and innovation ecosystems.

Significantly lowered through all of this is also the involvement of fluoroalkyl and polyfluoroalkyl substances, or what are known as PFAS, sometimes referred to as “forever chemicals”.

In 2023, it was reported that Johnson Matthey had signed an investment agreement with the Jiading District in Shanghai to help accelerate the hydrogen economy in China by building a new catalyst-coated membrane production facility, providing production capability for multiple PEM fuel cell applications and PEM electrolysers, which turn water into hydrogen and oxygen.

Catalyst-coated membranes typically consist of platinum cathodes and iridium anodes, which are applied to solid membranes in a way that reportedly maximises hydrogen production.

Water flows into the catalyst-coated membrane, where an iridium catalyst uses electrical energy to break water molecules into oxygen, protons and electrons. The electrons are driven through the external circuit and protons then cross the membrane. A platinum catalyst puts the protons and electrons back together to form hydrogen.

This membrane is a key performance-defining component in fuel cell electric vehicles (FCEV). China has said it aims to have a million FCEVs on its roads by 2030.

TURNING GREY HYDROGEN TO GREEN HYDROGEN

The French company Lhyfe this week drew major attention to steps that are being taken to convert grey hydrogen, already in use, to green hydrogen, and made reference to its use of PEM technology.

Lhyfe reported that Europe is currently consuming seven-million tonnes of grey hydrogen and mention was also made of the large volumes of grey hydrogen produced by South Africa’s synthetic fuels and chemicals producer, Sasol.

“There's nothing that is easier to do when decarbonising a customer, a plant, an industrial player, than switching from grey hydrogen to green hydrogen, so that's what we are doing. We have been building new plants to address the new market,” said Lhyfe founder the CEO Matthieu Guesné during an online presentation covered by Mining Weekly.

“Decarbonising existing industry is as important as decarbonising mobility because 23% of CO2 emissions are linked to energy usage by industry, so it is important to understand that the market for green hydrogen is already there,” Guesné pointed out..

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation