Pioneering a greener construction future for Africa

Localised laboratories strengthens Chryso's support across Africa

Chryso® Quad empowers the construction industry to overcome construction and sustainability challenges

LC3 cements will make a huge advance in making cement greener around the world

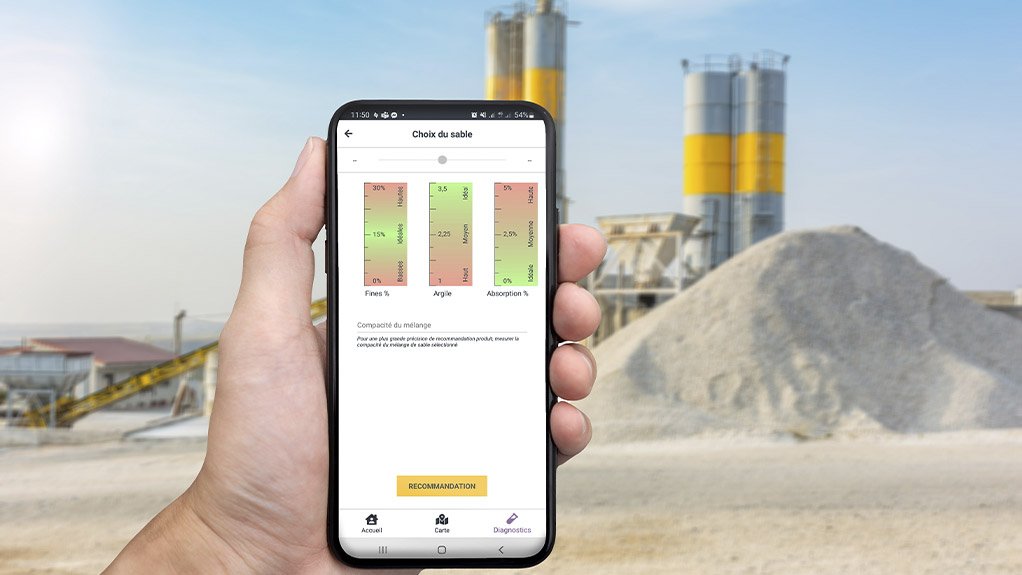

Chryso® Quad App is simplifying mix design optimisation with real-time insights for better concrete performance

This article has been supplied.

As Africa’s construction industry embraces greener practices in meeting its infrastructure needs, CHRYSO is on board with a rebranded focus on sustainability.

Having merged with GCP Applied Technologies under the Saint-Gobain banner, Chryso’s new identity reflects its commitment to eco-friendly innovation, according to Sibu Hlatshwayo, Managing Director of Chryso Southern Africa. This focus is at the core of its mission to responsibly support Africa’s infrastructure growth.

“We are addressing local needs while helping customers reduce CO₂ emissions,” says Hlatshwayo. “Our new green branded identity signals our dedication to pioneering the future of construction by creating practical, sustainable solutions.”

He highlights that Chryso’s approach centres around four pillars: innovation, proximity, partnership and sustainability. An example of its innovative edge is the Chryso® Quad Range, which allows contractors to use local aggregates that fall below traditional standards, to minimise transport distances and reduce carbon emissions.

“Our Chryso Quad app complements our technical capability, guiding users to the best products based on specific aggregate characteristics, while our clay testing kit helps ensure quality results,” he explains. “Our Chryso EnviroAdd Range further reduces the environmental impact of construction by lowering clinker content in concrete mixes, as clinker is one of cement’s most energy-intensive components.”

Another breakthrough is Chryso’s innovations related to limestone calcined clay cement (LC3), a more sustainable alternative to traditional cement that blends limestone and clay to produce a greener concrete.

“Proximity is also a critical aspect of CHRYSO’s strategy, as we consider ourselves as a ‘multi-local’ business – rather than just multinational,” he says. “Our African footprint is well equipped to meet specific local needs with our facilities and our sales and technical support teams. By expanding our network of local laboratories – recently opening a new facility in Kenya, for instance – we can test raw materials locally and quickly to provide optimised solutions.”

Through more localised production, such as its manufacture of cement additives in Ghana, customers have the advantage of quicker turnaround times and reduced logistics costs, as well as the convenience of purchasing in local currency.

“CHRYSO is also driven by a passion for collaboration,” says Hlatshwayo. “Climate change requires a united approach, so we work with partners across the construction ecosystem to enhance our impact.”

Sustainability is at the heart of Chryso’s mission, and the company shares both admixture solutions and specialised knowledge to help customers to reduce their environmental footprint. The Chryso Academy is a valuable resource in this mission, offering courses to contractors, universities and other stakeholders to promote sustainable construction.

He concludes that sustainability needs to include renewed attention on the circular economy, as Africa’s rapid urbanisation is demanding increased recycling of concrete. This is another area where Chryso admixtures are playing their role.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation