Redefining Heavy-Duty Operations with High-Performance Battery Solutions

This article has been supplied.

In the competitive world of logistics, manufacturing and material handling, equipment downtime is not just an inconvenience, it is a major threat to productivity and profitability.

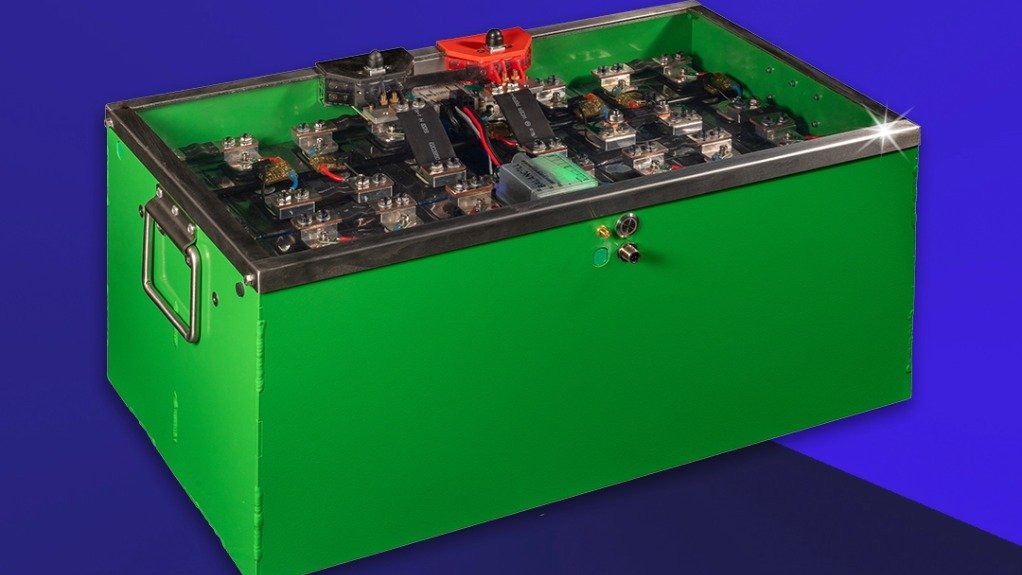

Industrial Power, a division of CFAO Equipment, is meeting this challenge head-on with advanced high-output lithium-ion battery solutions that are transforming how businesses operate.

Boosting output with smarter energy

Industrial Power’s high-performance lithium-ion batteries are engineered for fast charging and extended run times, reducing the need for frequent recharges and minimising equipment downtime. The result is higher throughput and operational efficiency across the board.

Industrial Power National General Manager, Imtiaz Mahomed Ally, says with intelligent Battery Management System (BMS) at their core, these systems ensure optimal energy usage and real-time monitoring.

“This gives operations managers the tools they need to proactively manage fleet performance and prevent disruptions before they happen.”

Battery capacity is the key to continuous operations

In high-intensity industries, battery capacity is not just a technical specification, it is a critical operational consideration.

A higher usable capacity means longer runtimes and fewer changeovers, which translates into uninterrupted multiple-shift operations. In this respect, businesses benefit from needing fewer spare batteries, reducing capital investment and optimising floor space.

By ensuring peak productivity during high-demand periods, battery capacity directly contributes to operational reliability and efficiency.

Why choose Industrial Power?

Unlike standard battery options, Industrial Power delivers a longer lifespan of 4,000 to 5,000 cycles, ensuring a lower total cost of ownership over time.

Its solutions are built for resilience, performing reliably in a wide range of conditions. With real-time telemetry for voltage, health and temperature, businesses gain the insights needed for predictive, data-driven maintenance, thereby reducing the risk of failure and extending system life.

Additionally, strong local support in all major provinces and 24/7 technical service means maximum uptime and performance for users.

Innovation for elevating operations

Industrial Power’s innovation strategy is centred on next-generation lithium platforms that are both modular and scalable, making them suitable for operations of all sizes.

Ally says each client engagement starts with a tailored energy audit, ensuring the right solution for the job. “With proactive support, Industrial Power helps clients extend battery life, reduce waste and adapt to evolving operational demands.”

Crucially, innovation is sustainability-driven and aimed at reducing environmental impact while delivering smarter energy usage across industries.

Proven ROI - a case study with Toyota Material Handling

Ally shares a real-world example of Industrial Power’s impact from its collaboration with Toyota Material Handling.

“Thirty-two Toyota 2.5 Ton Forklifts powered by 52V554Ah Balancell lithium-ion batteries were deployed over a five-year period. The result was more than 19,000 average operating hours per unit and an impressive R9.8 million in operational cash flow improvements.”

This was achieved through:

- Reduced maintenance costs

- Zero battery replacements

- Significantly less downtime

- Increased equipment productivity

The crux of the matter? What may have seemed like a high upfront investment yielded a substantially lower total cost of ownership, underlining the long-term value of Industrial Power’s advanced battery solutions.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation