Robotic solution for machine tools industry

CONTROL CONCEPT Finding the right software structure is just as important as the hardware

AUTOMATIC STEPS All work steps between the manual loading and unloading of the feeder system are carried out automatically

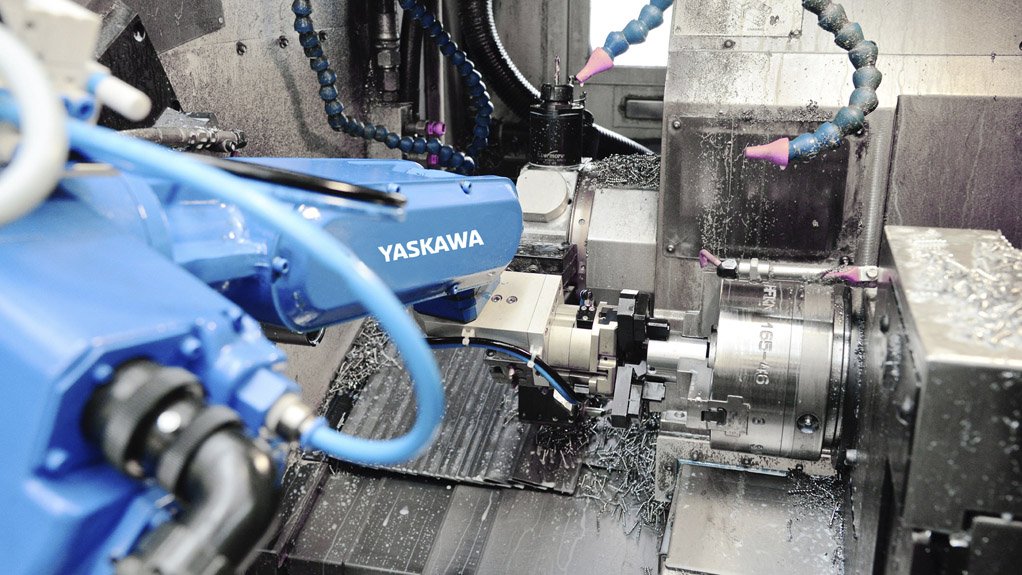

When it comes to the automated feeding of machine tools, the choice of the right robot set-up and manipulator is a key element in the planning process, says Japanese robotics company Yaskawa.

However, finding the right software structure is just as important as the hardware when planning the control concept.

A practical example shows how the cost-effective and user-friendly use of robots can work when configuring machine tools, the company says, explaining that its partner in achieving this was drive manufacturer Framo Morat, one of the world’s leading manufacturers of high-quality drive solutions.

“The core competence of the 400-employee-strong Framo is gear technology. In order to meet the high demand, all machine tools are configured for maximum performance. In the case of one counter-spindle lathe, there was still scope to increase productivity. Framo was on the look-out for an automatic loading solution for this machine,” the company adds.

Yaskawa further mentions that the robust standard solution needed to be highly flexible and easy to operate, and that it had to function reliably and take up as little space as possible.

“After closely examining the requirement specifications, it quickly became apparent that EGS’ standard feed system – the Flexiplex from the Sumo range – in combination with a tried-and-tested Motoman MH6 robot from Yaskawa could be the ideal solution,” automation technology company EGS sales manager Heiko Röhrig recalls.

He adds that EGS managed to meet all Yaskawa’s requirements using this standard configuration with slight modifications. All work steps between the manual loading and unloading of the feeder system are carried out automatically, and the task of Yaskawa’s Motoman robot is to automate Framo’s lathe.

“The MH6 takes unmachined parts from the in-feed conveyor and loads them with great precision into the main spindle of the lathe,” EGS notes.

It then removes the finished parts from the counter-spindle and sets them down on one of the four lanes of the output conveyor.

“The Motoman robots offer a broad spectrum in the 3 kg to 80 kg load-bearing capacity range. They can be mounted on floors, walls or ceilings without requiring further adaptation. They are also extremely easy to program at shop floor level and almost all manipulators feature a particularly slim line design,” Röhrig enthuses.

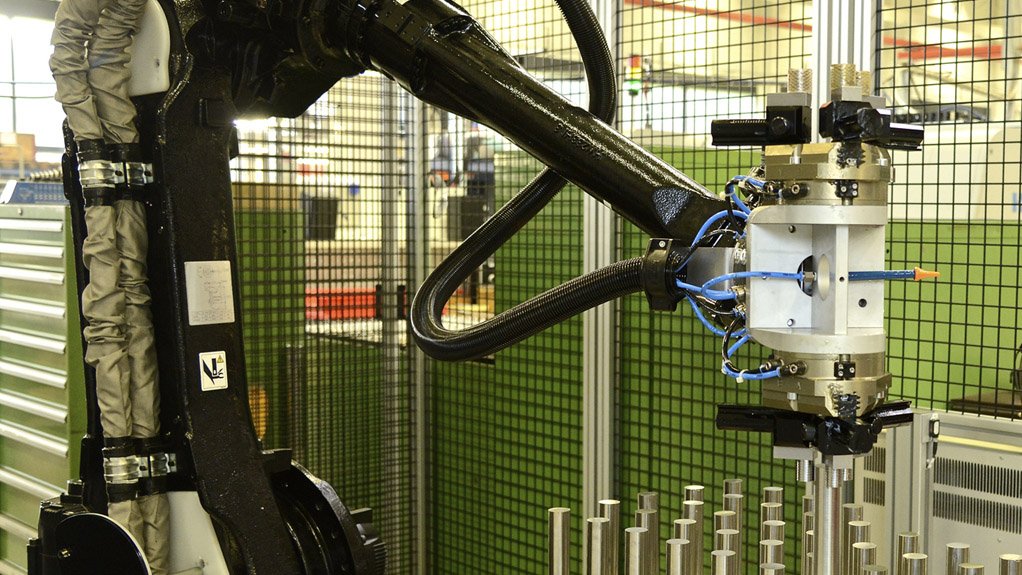

He further explains that another current system can be found at Högg Production Technology in Wattwil, Switzerland.

“The company employs 100 people in a production facility measuring around 10 000 m2, manufacturing precision components from almost all metal materials. Every year, several hundred tons of steel, aluminum, stainless steel, as well as various other materials, are machined.”

Högg relies on the latest production technology, involving more than 50 computer numeric control (CNC) machine tools and their consistent automation.

EGS has relied on Motoman robots from Yaskawa for many years, Röhrig explains, noting that system integrator CNC-Automation Würfel in Singen, Germany, recently automated a Mori Seiki NT 4250 lathe turning and milling centre.

“At first sight, the choice of a Motoman MS80W robot – mainly known from the welding field – was surprising. On closer inspection, it quickly became clear why this six-axis machine was the first choice for handling applications. Thanks to its slim shape, the MS80W manages with a relatively small footprint.”

He further adds that it can easily achieve any position with its reach of 2 236 mm, owing to its repeating accuracy of 0.07 mm, it is more than sufficiently precise for the loading and unloading of the processing machine and the picking up and loading of the parts into the workpiece carriers.

High-Performance Robots

The Motoman handling robots from the MH series are predestined for all automation tasks associated with the machine tool, Röhrig notes.

“The Motoman MH12 is Yaskawa’s fastest model in its class and is designed for a load capacity of up to 12 kg. In order to improve internal media guidance for the gripper, the robot manufacturer has increased the size of the hollow wrist joint of the dynamic six-axis robot from 42 mm to 50 mm.”

He explains that this significantly reduces the mechanical stress on the cables and that possible connection problems are eliminated and the programming and maintenance of the robot is simplified.

“The slim, streamlined design of the articulated robot not only reduces interfering contours between the machine and workpiece, but is also consistently compact in design and thus enables handling in confined spaces, as well as high robot density. Interferring contours caused by external media cables are also a thing of the past on the larger MH24,” Röhrig enthuses, adding that this is made possible by the hollow upper arm of the six-axis universal robot with a diameter of 50 mm.

Despite the hollow design, Röhrig insists that the high-speed robot is extremely powerful.

“It has a load capacity of 24 kg and a streamlined design with a small footprint. This makes the MH24 extremely versatile.”

MotoLogix

Meanwhile, Röhrig further mentions that, in order for industrial robots to develop their full performance capability, they must interact smoothly with production machines and control environments.

“For a long time, robot and machine controllers had to be programmed, controlled and maintained separately. However, while it is still technically possible, this conventional interaction between robots and machines involves a number of issues which can now be solved more simply.”

He explains that when using the conventional method, operating personnel have to be trained not just in international programming logic controller (PLC) standards but also possess skills in robot programming and control.

“What is more, redundant programming procedures mean that the source of failure is not readily evident. This makes it difficult to eliminate errors quickly and easily. Solutions have been put forward in the past and at the turn of the millennium, the trend was towards integrating machine control systems in robot control.”

Given that PLCs are now high-capacity and can be expanded on a modular basis, Röhrig notes that the approach adopted today is the direct opposite: the robot is integrated directly in the machine through the PLC as one of many elements.

“Yaskawa offers a highly effective solution called MotoLogix.”

When it comes to the optimum, application-specific implementation of complete system solutions in the machine tool industry, robots often lie at the heart of the system, Röhrig enthuses.

“This requires a broad range of products and solutions, such as those offered by Yaskawa, ranging from manipulators to controllers and more.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation