Sandvik CH865i unlocks major production gains at Ghana gold mine

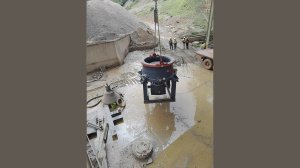

The bottom shell of the old crusher is being removed to make way for the installation of the new Sandvik CH865i cone crusher supplied by Sandvik Rock Processing

Components for the new Sandvik CH851i cone crusher supplied by Sandvik Rock Processing being offloaded on site at a gold mine in Ghana

A view of the subframe in position before assembly of the bottom and top shells for the new Sandvik CH851i cone crusher

The bottom shell of the new Sandvik CH851i cone crusher supplied by Sandvik Rock Processing being offloaded from its stand and lowered to the ground

The bottom shell of the new Sandvik CH851i cone crusher supplied by Sandvik Rock Processing positioned on the ground in preparation for lifting into place

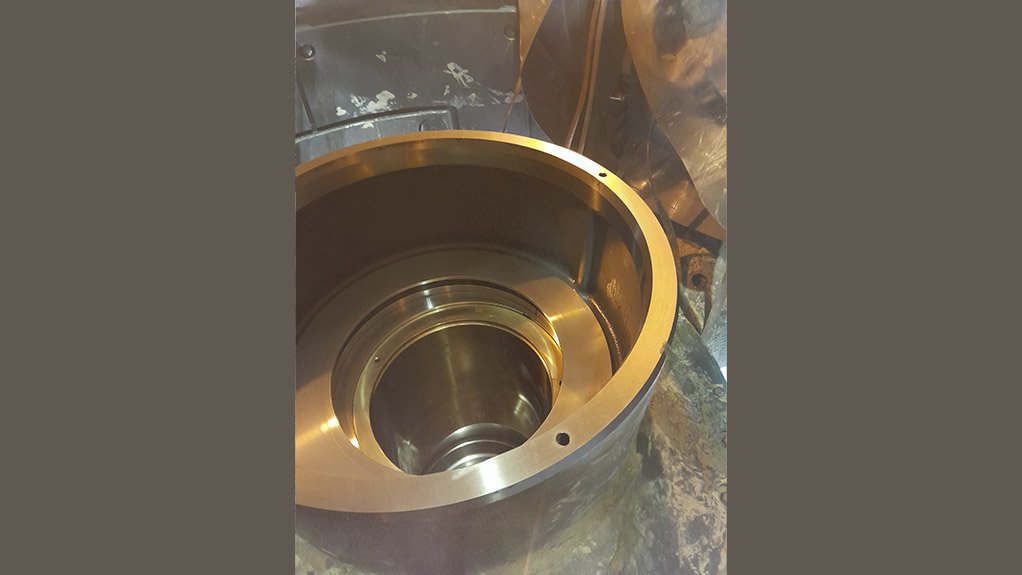

A view of the eccentric bush within the Sandvik CH865i cone crusher assembly

Production at a gold mine in Ghana was recently ramped up with the help of the advanced Sandvik CH865i cone crusher, following close collaboration with the Sandvik Rock Processing team in Ghana to identify the optimal solution for the site’s specific conditions.

The need to raise throughput levels at the mine had become pressing, with the mine’s stockpile quickly depleting due to the strategic demand for more ore. According to Michael Okunola, Service Manager for Sandvik Rock Processing West Africa, the solution also had to account for space limitations within the plant.

“The mine was considering adding another cone crusher to the existing lineup of three crushers in the plant but with limited space available, we began exploring other options,” says Okunola. “Ultimately, the team was guided by the fact that the second of the three tertiary crushers was handling the bulk of the throughput, and we realised we could make a significant impact by addressing the capacity opportunities at that point in the circuit.”

The mine was already operating three Sandvik CH660 cone crushers in the tertiary circuit and turned to Sandvik Rock Processing for a solution that would deliver the same exceptional performance and reliability, he says.

“Under the mine’s previous production regime, the Sandvik CH660s comfortably met the required capacity,” he explains. “However, with the new production targets, a crusher with higher throughput capacity was needed.”

In this application, the Sandvik CH865i is capable of delivering up to 400 tph - nearly double the previous throughput - significantly boosting the mine’s overall production.

“The optimal solution was achieved by replacing the second - or middle - CH660 cone crusher in the mine’s tertiary circuit with a Sandvik CH865i model,” says Okunola. Once the new unit’s components arrived on site, Sandvik Rock Processing’s technical team collaborated closely with the mine’s team to implement the necessary adjustments within the plant.

These modifications included installing a new locally manufactured hopper to accommodate the taller dimensions of the Sandvik CH865i crusher. The installation had to be carried out while the plant remained operational, requiring special measures to manage dust and maintain a safe working environment.

“We worked with the mine to decommission the existing unit and implement the necessary concrete, steelwork and other critical infrastructure for the new crusher,” he explains. “The Sandvik Rock Processing team then assembled the Sandvik CH865i on site using the delivered components - including the sub-frame assembly, top shell, bottom shell and main shaft assembly - all in line with our strict OEM standards.”

“Following successful commissioning, the increase in output delivered a rapid return on investment for the customer confirming that the decision was the correct one,” says Okunola. To further support ongoing performance, the mine also entered into a service level agreement with Sandvik Rock Processing, ensuring that a dedicated engineer is based on site to maintain and optimise equipment efficiency.

“Our team is on hand to closely monitor the condition and operation of our crushers, and to ensure that maintenance such as liner replacement and lubrication are regularly performed,” he says. “Our OEM procedures and attention to detail give the customer peace of mind that the new crusher is delivering as expected, with no unplanned downtime to disrupt production.”

Among the benefits that the Sandvik CH865i cone crusher brings is its ease of operation and maintenance, he adds. For instance, it does not need the application of casting compound when replacing liners which also represents a significant cost saving.

Equipped with the hydraulic Hydroset™ system for safety and setting-adjustment functions, the unit is also intelligent - ready to be connected to Sandvik’s Automation & Connectivity System (ACS). This automatically adapts the crusher to varying feed conditions ensuring the best performance constantly.

“The value of ACS lies in its ability to monitor key aspects of the crushing process including the electric motor’s power draw, hydrostatic pressure, closed-side setting and oil temperature,” says Okunola. “It also tracks the performance of individual components such as the lubrication pump and the Hydroset™ pump as well as rotation speeds and feed rates. All of this enhances operational transparency by flagging any deviations from normal performance.”

He highlights that, after the commissioning of the new Sandvik CH865i unit, Sandvik Rock Processing conducted on-site training for the mine’s team, on both operation and maintenance.

“Our training also emphasises the safety aspects of working with our equipment, as our strong safety focus supports the mining sector’s drive towards zero harm,” Okunola concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation