Tel-Screw Profile

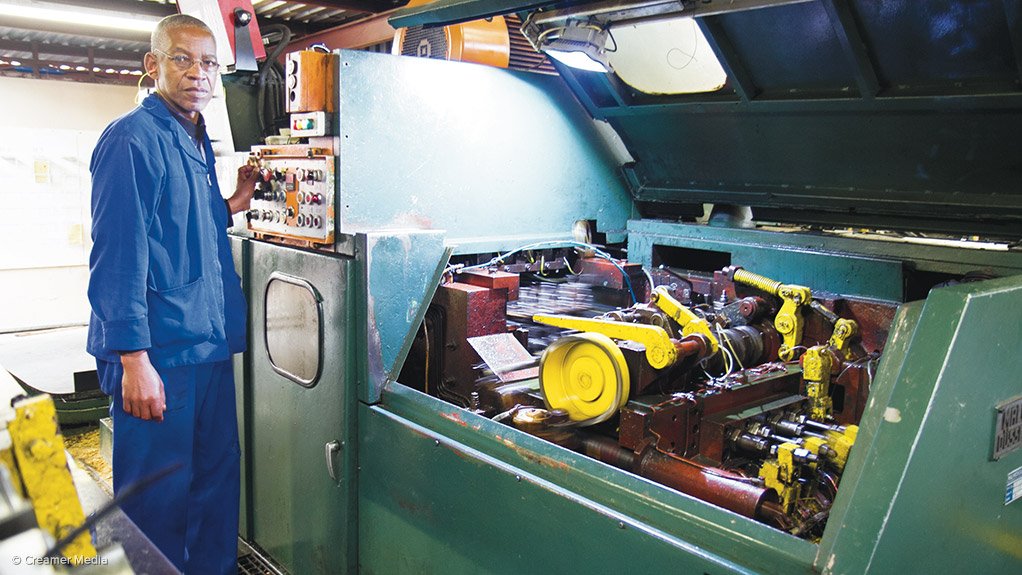

Standard, special fasteners and overhead line products manufacturer Tel-Screw, which was established in 1970, is equipped to do all types of bending and forming. The company’s capabilities include cold heading, hot forging, thread rolling, screw cutting, hot bending, cold bending, automatic machining, computer numerically controlled (CNC) machining, toolroom facilities, milling, robotic welding, pressings, guillotining and light fabricating. The company’s CNC machining section was recently upgraded with a bar feed CNC machine for mass-produced turned components.

The company is situated at 25 Lorna road, Muswelldale, Boksburg North, and is located on 10 000 m2 of land of which 8 000 m2 is under cover, with two 20 t weigh bridges to monitor incoming raw material. Tel-Screw is 60%-owned by The Bolt Business Trust and 40%-owned by The Tram Trust and has a yearly turnover of R60-million.

Further Tel-Screw, which is ISO 9001:2008-compliant, has an order book of R12-million and employs 160 people. It is currently working on several contracts, one of which is for Eskom, as well as other short-term automotive supply contracts and the supply of mining consumables, also on a short-term basis.

Tel-Screw has also commissioned its own wire processing plant to assist with an increasing demand in its cold heading department. To improve energy efficiency, the company is in the process of upgrading its induction heating facility with state-of-the-art technology for the forging department. This has led to a 30% increase in plant efficiency over the last two years.

As a South African manufacturer, the company feels responsible for the promotion of local employment. It prioritises keeping it local and encourages its clients to buy from local manufacturers. It is a proudly South African manufacturing company.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation