The Lube KitchenSeries part 10: corrosion inhibitors – your oil’s armour against rust and more

This article has been supplied.

By: Steven Lumley - technical manager, WearCheck

(Virtual Showroom) Fighting against rust in lubrication systems is an age-old battle. This edition of WearCheck’s Lube Kitchen Series highlights the important role played by corrosion inhibitors.

Humankind has grappled with the issues of rust and corrosion for over 3,000 years – pretty much since the iron age in 1200BC when our forefathers started making tools and weapons from iron and iron alloys.

It wasn’t until the 20th century, when corrosion was determined to be a chemical and electrochemical phenomenon, that real progress was made with the development of specialised lubricants with anti-rust properties.

As with many of the advancements in the lubricant industry, World War II accelerated the development of more effective oil additives, and researchers began to explore the use of corrosion inhibitors to protect metal surfaces in lubricated systems.

Corrosion is defined as the destructive alteration of metal by an electrochemical or chemical reaction between the metal and its environment, resulting in change and weakening of the metal’s properties. All metals, with the exception of noble metals, are unstable under atmospheric conditions, which allows them to be converted into their oxidised form.

Electrochemical corrosion involves the reaction of ferrous (iron-based) metal or its alloys in a two-step process in the presence of an electrolyte, most typically water. This reaction results in the formation of iron oxide, commonly known as rust.

Chemical corrosion involves the interaction of metals with aggressive chemical species, like acids produced from the oxidation of lubricants or additive by-products, which can lead to the formation of oxidised metallic compounds and the deterioration of the metal. Unlike electrochemical corrosion, chemical corrosion does not require an electrolyte like water.

Corrosion and rust inhibitors are both used in a variety of lubricants to protect metal surfaces, but they serve slightly different purposes in terms of the metals they protect, and may have different mechanisms of action.

Corrosion inhibitors help slow down the deterioration process in non-ferrous metals like copper and lead. These inhibitors form an inactive film on the metal surface by complexing with metallic ions at the surface. Some corrosion inhibitors also work by neutralising corrosive acids formed from oil and additive degradation byproducts.

Rust inhibitors are a specific subset of corrosion inhibitors that primarily focus on preventing rust of iron and steel surfaces.

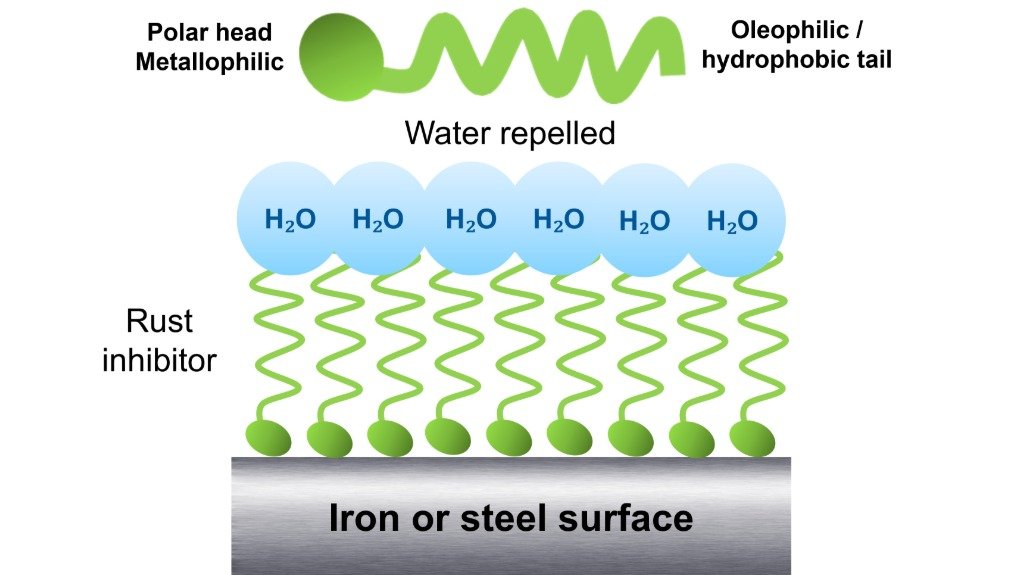

Rust inhibitors are used in lubricant formulations to slow down corrosion of iron alloys. They function by physically adsorbing onto the metal surface. These rust busters have polar head (metallophilic) groups that attach to the metal surfaces and oleophilic hydrophobic tails that form a film to protect metal surfaces from the effects of water, acids, and air.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation