Tunnel-boring machines for Polihali transfer tunnel inspected ahead of delivery to Lesotho

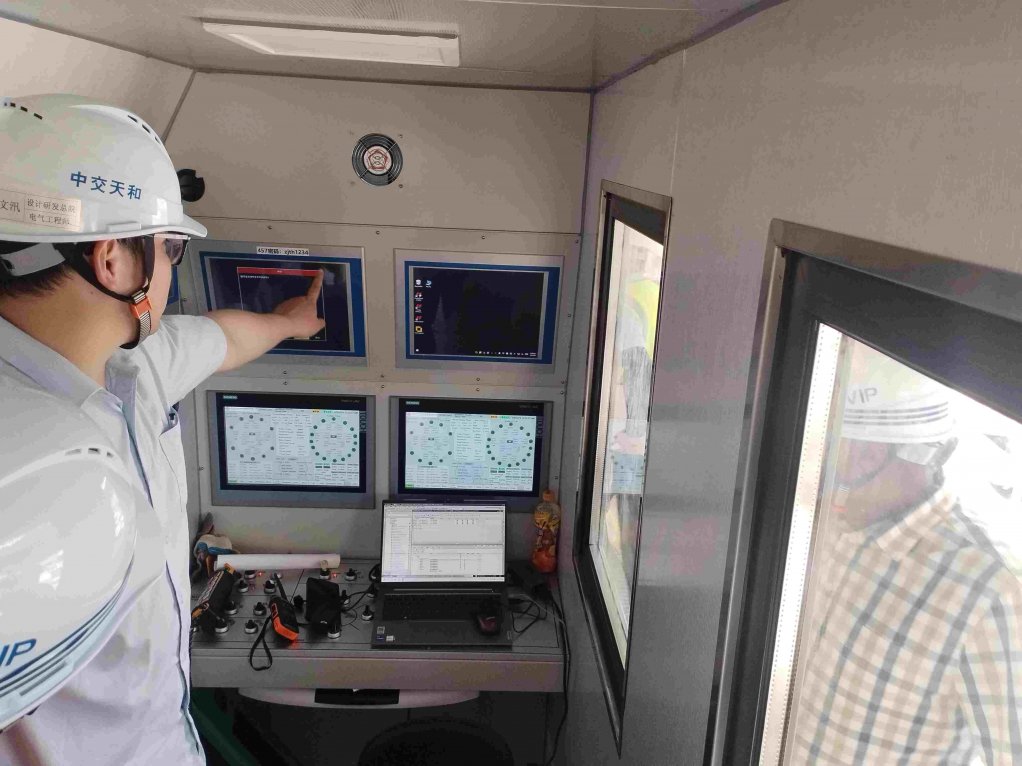

INSPECTION CHECK The factory acceptance tests of the tunnel-boring machines were undertaken from May 8 to 11

The tunnel-boring machines specifically designed and manufactured to excavate the Lesotho Highlands Water Project’s (LHWP’s) 38 km transfer tunnel from Polihali to Katse will soon be making their way to Lesotho.

The 5.39-m-diameter tunnel-boring machines, with 415 m backup systems, are expected to arrive in Lesotho later this year.

This followed a recent inspection by a team of engineers and tunnelling experts from the Lesotho Highlands Development Authority (LHDA), along with consultants and contractors on the Polihali transfer tunnel.

The factory acceptance tests of the tunnel- boring machines were undertaken from May 8 to 11, at a CCCC Tianhe plant in Changshu City, Jiangsu Province, China, by LHDA senior engineers and various representatives from Metsi a Senqu Khubelu Consultants (MSKC), the Kopano Ke Matla joint venture (JV) and US company Robbins.

MSKC designed the tunnel and provided the tunnel-boring machines’ specifications, and Robbins designed the machines, while the Kopano Ke Matla JV is constructing the tunnel.

The inspection aimed to ensure that the tunnel-boring machines, which have been designed to handle the challenging basalt rock formations in the Mokhotlong and Leribe districts, where the transfer tunnel is being constructed, meet the specifications for the excavation of the Polihali transfer tunnel.

Safety features were a primary focus of the acceptance test.

“We verified the design of the tunnel-boring machines, their functionality and adherence to safety standards. This included examining the cutterheads, backup systems and segment erection mechanisms,” explains Phase II senior projects engineer Neo Thinyane.

In addition to assessing the functionality of the muck removal system, conveyor belts, power supply, ventilation, water supply and dewatering systems, the teams checked for adequate walkways, head clearance and body width for workers, gas detection systems for hazardous gases like methane, and the functionality of alert alarms.

“Fire detection and suppression systems were also scrutinised, given the risky nature of tunnel excavation and tunnel-boring machine operations, as were the crucial safe extraction procedures,” Thinyane continues.

The tunnel-boring machines are equipped with refuge bays containing life-support systems, including first-aid kits, oxygen tanks, respirators and air filtration systems, as well as backup power and cooling systems to ensure uninterrupted operation in case of power outages.

The Polihali to Katse transfer tunnel is one of the main works components of LHWP Phase II, and will transfer water by gravity from the Polihali reservoir to the Katse reservoir.

The excavation will use both tunnel boring and drill and blast methods from both ends.

The Polihali transfer tunnel works include the intake works and gate shaft at the Polihali reservoir, outlet works and gate shaft at the existing Katse reservoir with an underwater connection to the lake, and access adits to the waterway and associated construction infrastructure.

Notable progress has been made on the intake, outlet works and access adits.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation