Value-for-money centrifugal pumps to change process

The food and beverage industry is continuously looking for solutions to increase production efficiency with extremely high system pressure applications becoming more common, especially in typical reverse osmosis applications for whey, wine and beer filtration.

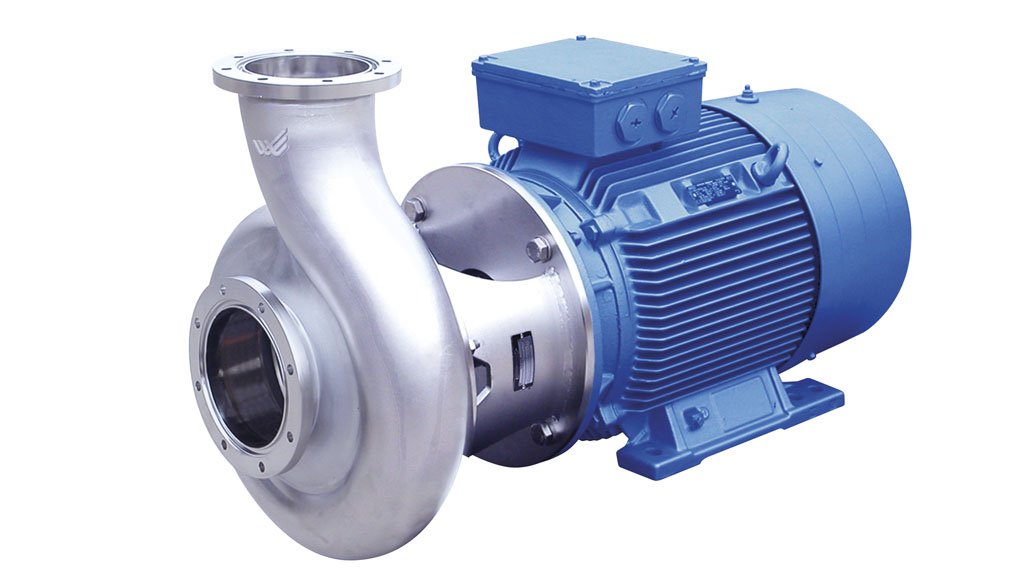

With this new trend, global food industry partner Packo – which is represented in South Africa by industrial equipment supplier Verder Pumps – notes that this has led to a new innovative hygienic addition to the Packo pump series, namely the FPP2 and IPP2.

“These hygienic pumps can operate at a maximum inlet pressure of 40 bar, a flow rate of 50 m³/h at a differential pressure of 7 bar. These unique and performant pumps were introduced in the market during the last international shows Canadian Food Inspection Agency, Rennes and Anuga in Cologne,” the company explains.

The hygienic, high-quality and robust pump range is especially developed to operate under the most severe conditions, the company enthuses.

“It is fully machined and constructed in thick stainless steel, which make it suitable for handling an inlet pressure up to 40 bar,” the company further explains.

Flow rates higher than 50 m3/h are expected to be available very soon.

For this new development, the company notes that the typical Packo Pumps philosophy has been followed: a construction with standard components such as International Electrotechnical Commission, known as IEC, motors and mechanical seals in accordance with European standard EN12756, which has a hygienic design with electro polished surface as a standard.

In addition, Packo notes that its FP stainless steel centrifugal pumps are designed according to the strictest cleanability standard (EHEDG, 3A) and mainly used in the food and beverage industries.

The Packo range also consists of the FP63, FP66 and FP68 pumps – which are small, single stage, stainless steel centrifugal pumps.

“They offer good value for money, combining a sanitary design in a modular and functional construction. This range is limited to 45 m³/h / 200 US.GPM - 26 m / 85 ft - 2.2 kW / 3 hp,” the company explains.

Features

Features of the Packo Pump range include a cleanable stainless steel 316L construction, as well as all wetted parts being constructed of stainless steel 316L or higher.

Pump casings are also made of cold rolled plate, which is non-porous and extremely smooth, the company notes. Impellers are made from an investment cast and receive follow-up treatment.

All stainless steel parts in contact are electro polished as a final surface treatment, which leads to a low micro roughness with a highly increased resistance to adhesions, thereby resulting in improved ease of cleaning and bacteriological purity.

The company also explains that electro polishing also offers a highly improved corrosion resistance owing to a higher percentage of the noble materials chromium and nickel at the surface.

The crevice-free design of all parts in contact – such as the pump casing, back plate, impeller and seals – in combination with the optimal internal turbulence fully meets requirements for hygienic standards.

The range also boasts a functional design and stainless steel motor adapters, the company adds. Stainless steel motor bases and shrouds are also available.

The open impeller has the following advantages: low net positive suction head

values, high quality air-handling, non-clogging, no axial stress on motor bearings, low pressure in seal cavity and extended seal life.

The range also has a higher efficiency, less turbulence and gentle product handling, as well as availability of a range of seal types, configurations and material combinations.

Field of Application

Further, the company notes that the Packo FP pumps are mainly used in the processing industries.

Some actual applications include milk, egg, soya, beer, wort, wine, fruit juices, soft-drinks, alcohol, yeast, starch, vegetable and ethereal oils, sugar solutions, brine, blood, light chemicals, solvents, detergents, water, as well as clean-in-process solutions.

The range is limited to 45 m³/h / 200 US.GPM - 26 m / 85 ft - 2.2 kW / 3 hp.

“Packo pumps are also an important link in the reliability and the improvement of the energy efficiency of our customers. To this end, we develop and constantly improve more pumps tailored to our clients, for the most diverse applications,” the company concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation