Company gears up for growth in pumps industry

NEW PRODUCTS Pump and Abrasion’s Battlemax range offers several new products for different applications

STOCK FORECASTING Pump and Abrasion has increased its stockholding to cater for companies’ specific requirements

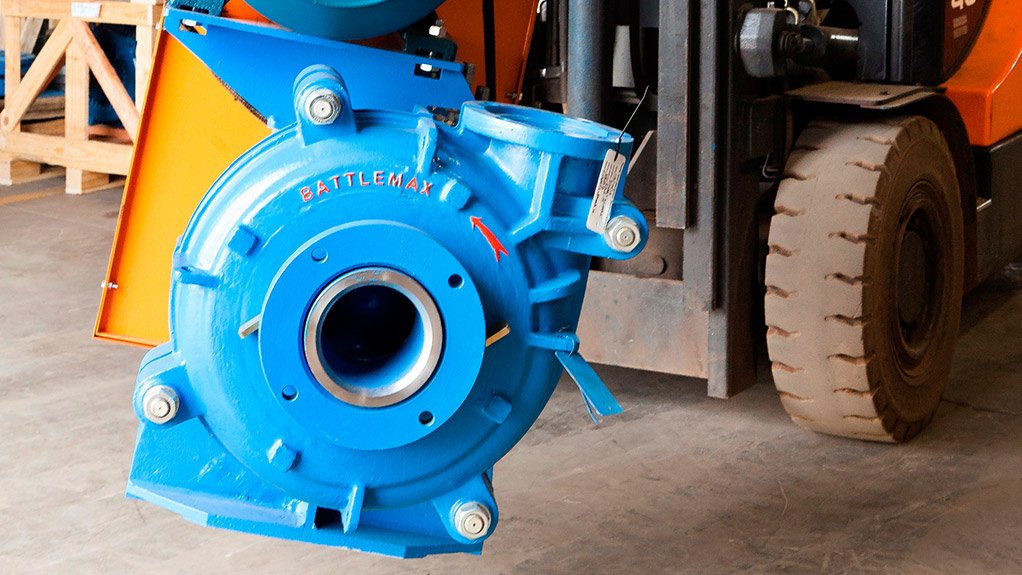

Slurry pumps supplier and pumps solution specialist Pump & Abrasion Technologies has introduced several new products to its Battlemax range onto the market over the past few years, including the new 35% Ultra High Chrome Alloy and high-abrasion-resistant polyurethane liners, which includes the acid-resistant poly- urethane liners, states com- pany marketing director James Pienaar.

These products were designed to increase the life cycle of clients’ various applications.

“The Ultra High Chrome product has been shown in certain applications to extend the previous life cycles in some instances by 30% or more,” Pienaar points out, adding that, during the testing of these products in these applications, the service periods between the pump’s life cycle and applications were dramatically increased, which indicates the product’s qualities, and also the amount of savings on down-time to the client.

“There has been a huge increase in demand for the 35% chrome Battlemax product, to the extent that certain clients have standardised all their inventory on the Ultra High Chrome product, owing to its benefits in terms of cost of ownership,” he says.

Owing to certain applications demanding acid-resistant products in especially low pH to high pH environments and the company’s commitment to increase its offering to clients, the acid-resistant polyurethane products were introduced into the Battlemax ranges offering, Pienaar adds.

Pump & Abrasion also offers other products, including acid-resistant alloy products for acidic applications.

“We do not always want to supply the same products to clients, as the technology for these products is constan-tly evolving and products are improved. However, we want to ensure a supply of product that reduces costs and enables app-lications to run for extended periods at a time,” he says.

Pump & Abrasion has increased its stockholding signi-ficantly in the past year, which has enabled the company to have nine out of ten products in stock, which ensures that it can cater for certain companies’ specific requirements, adds Pienaar.

“As slurry pumps are used in extremely abrasive conditions, with lead times in the pumping industry also being a key challenge, the company commits to supplying high-quality products for customers at a reduced lead time and which ensure the cost-effective operational life cycles of the pumps,” he says.

The company undertakes stock forecasting according to each client’s needs and increases the stock inventory for the client to ensure that stock supplies are replenished as quickly as possible, if necessary, Pienaar notes.

To enhance its service offering, the company provides skills training to ensure easy installation and operation of the pumps. “Installing the product with the correct settings is very important, and failing to do so can cause premature failure or downtime,” Pienaar says, adding that, by having these training workshops on how to assemble and operate the pumps more efficiently, the clients can benefit from the added reduction in maintenance costs.

The company also monitors the use of spares after the pumps have been installed. “We use products during a trial period to determine whether longer life spans of the product can be obtained, and that will enable clients to have better planned maintenance schedules,” he notes.

An advantage of the com- pany’s offering includes the technical knowledge and ability to identify problems of applications on site, Pienaar notes.

“We assisted in solving major operational issues after a full site audit was conducted on certain applications at a mine, which will increase the life cycle of the pumps and spares, as we have proven that we are techni- cally capable of assisting plants,” he adds.

Pump & Abrasion notes that more mines are becoming cost conscious with regard to operational efficiency, which sees them procuring cost-efficient services and high-quality products at good prices, notes Pienaar.

Owing to the current unrest and strikes in the mining sector, the company has also noticed increased activity in pump reconditioning and rebuilding during operational downtimes of the mines.

Currently, about 30% of the company’s business is genera-ted from pump reconditioning and repairs.

Pienaar comments that company plans for the year include creating a larger African footprint, in locations such as Tanzania, Zambia, Ghana and the Democratic Republic of Congo, through the marketing and rolling out of its Battlemax range of pumps, while strengthening its South African base by continuing its servicing contracts with the large mining houses.

“With the expansion projects, new mining projects, mine- ral production and new mining mandates, Africa is growing at such a rate that the pumps industry will continue to flourish and expand,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation