Manufacturer anticipates good connections

DEEP SEATED The vast skills and technologies of automotive component maker voestapline has set it apart as a manufacturer of choice in South Africa

STEELING THE SHOW The steel manufacturing capabilities of voestalpine's Gqeberha branch position it well in the automotive components manufacturing sector

The 2025 iteration of the National Association of Automotive Component and Allied Manufacturers (NAACAM) Show will be attended by automotive components manufacturers and suppliers from across South Africa.

This includes representatives from global steel and technology group voestalpine High Performance Metals Africa, who will attend to forge an alignment between original-equipment manufacturers (OEMs), Tier 1 suppliers and component manufacturers.

The NAACAM Show, hosted in partnership with the Automotive Industry Development Centre – Eastern Cape, will be held at the Boardwalk International Convention Centre, in Nelson Mandela Bay, on August 13 and 14 and will showcase the capabilities of the domestic automotive component manufacturing sector.

“voestalpine views NAACAM as a platform to not only engage with key stakeholders in the industry but also identify potential areas for future collaboration,” says voestalpine national steel sales manager Charmanita Hoggons.

The company continuously invests in advanced material solutions and digitalisation and hopes to collaborate with OEMs with the same values.

“We look to gain deeper insights into current automotive industry trends and challenges, as well as strengthen existing relationships and establish new industry connections,” she adds.

Automaking

voestalpine’s scope of expertise across its four divisions includes supporting leading OEMs and automotive suppliers in terms of lightweight construction; and providing body-panel manufactured and engineered products such as ready-to-use parts made from high-quality steel grades or premium metal powder.

The company’s e-mobility and other powertrain ranges help its clients meet the specific requirements of different powertrains, including valve steel, electrical steel strip, engine mounts and fuel tank vent pipes.

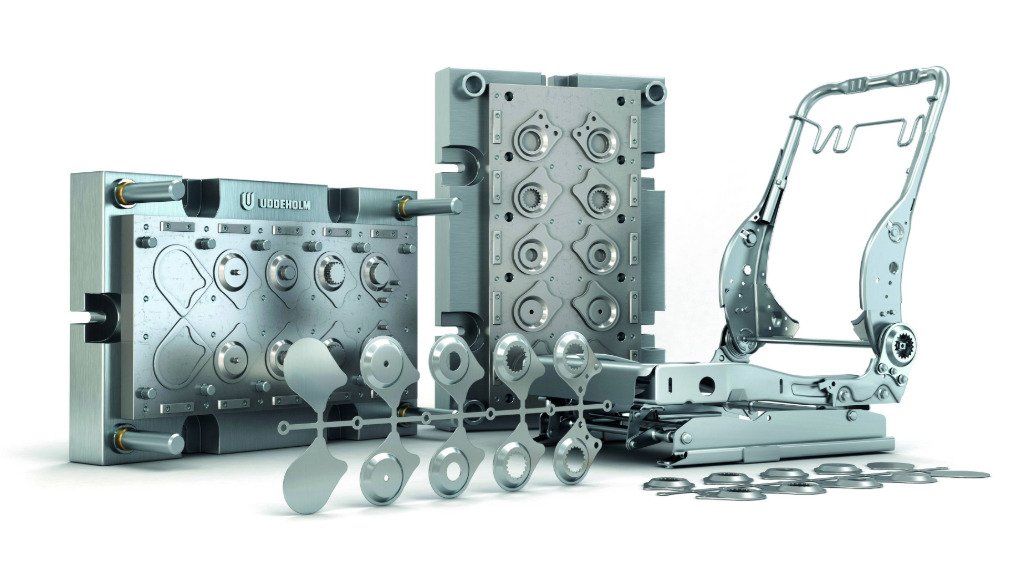

voestalpine’s innovations include high-performance tool steels designed to meet evolving automotive design and safety requirements, as well as powder metallurgy and additive manufacturing advancements for precision tooling.

The most frequently supplied solutions include cold- and hot-work tool steels for stamping, forming and die-casting applications.

“These grades are selected for their durability, dimensional stability and wear resistance, all of which are essential for high-volume automotive production,” states Hoggons.

These innovations support local manufacturers in achieving efficiency, consistency and cost savings in their production processes.

Further, the company is committed to supporting the industry’s transition to low-emission, energy-efficient processes by providing materials and solutions aligned with green manufacturing principles as well as collaborating with local partners to introduce smart manufacturing technologies and sustainable steel innovations.

Hoggons says voestalpine continuously undertakes research into alternative production methods to help achieve climate neutrality and is working to design technologies to decarbonise processes and reduce CO2 emissions in the long term.

“Our attendance to network at NAACAM underscores our dedication to being a reliable and forward-thinking partner in the value chain,” she concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation