Tracking system well received locally

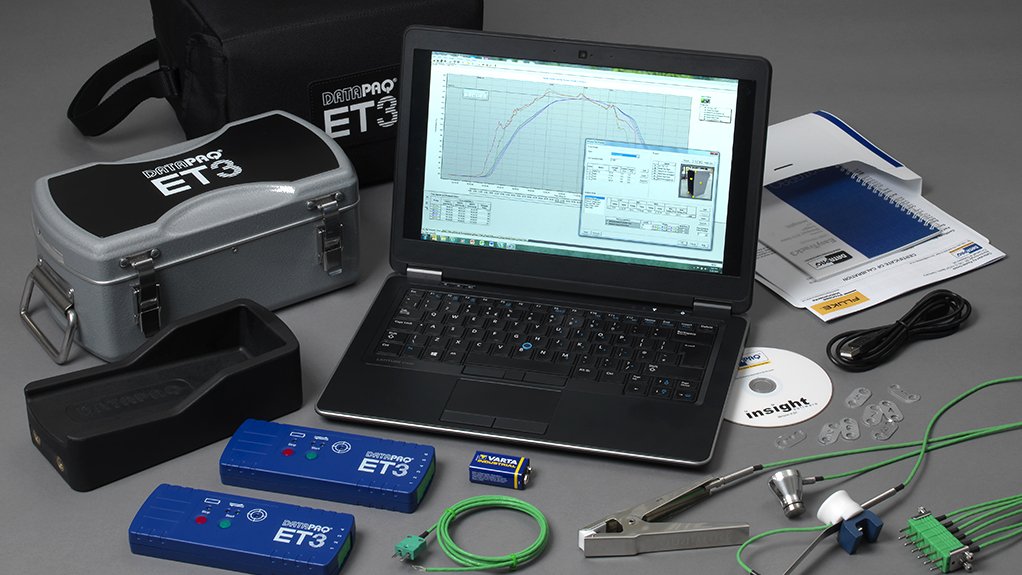

HOT SHOT The new ET3 system collects and correlates temperature data from within an industrial oven

Automation and control solutions provider Raytek & Control (R&C) Instrumentation says its newest heat tracking system, the Easy Track 3 (ET3), has been well received by the local automotive industry, where it is used predominantly in paint curing ovens.

The ET3 is manufactured by oven tracking systems manufacturer Datapaq – part of industrial test, measurement and diagnostic equipment manufacturer Fluke Process Instruments Group of in Cambridge, in the UK.

The ET3 system comprises a multichannel data logger, precision thermocouples and a thermal barrier that enables the logger to travel through the oven together with the product.

All related and needed software to acquire and compile the data from the logger is provided with the system.

“When employing heat treatment as part of a manufacturing operation, the critical information needed is the temperature of the product as it is taken through the heating process,” says R&C Instrumentation sales engineer Gerhard Otto.

The information acquired from the logger is commonly known as temperature profiling and is used to describe the process of recording and interpreting the temperatures of products and/or air through a heat-treating process, he adds.

Achieving the correct temperature – and for the correct time – can significantly affect the quality of the product, whether it be the correct cure on a painted car body or the physical properties of a heat-treated part.

The temperature data is measured continuously using thermocouples linking the datalogger directly to the product at different locations as it travels through the oven or furnace.

The measured temperature readings are stored in the datalogger, which moves along with the product and is protected from the hostile environment of the process by a thermally insulated box referred to as a thermal barrier.

Either during the process, using telemetry, or after the process, the profile data is retrieved from the datalogger and transferred to a computer software package that allows for the data to be reviewed, analysed and reported.

Temperature data collected from the profiling operation provides a graph or profile showing what temperatures the product or oven was exposed to during the heating procedure.

The information creates a thermal fingerprint of the product and process, which is critical to the understanding of the heating operation.

“Process engineers know what the perfect profile for their product should be; variations from the ideal indicate a potential problem or unacceptable quality,” stresses Otto.

Analysing the profile enables engineers to verify products of the highest quality, increase throughput and solve production problems.

Ease of Application

Otto says the ET3 makes it easy for engineers to interpret the profiled data by converting raw data into meaningful process information by using either the Datapaq EasyTrack or Datapaq EasyTrack Professional software.

The Datapaq ET3 calibration certificate stored onboard makes complete traceability of equipment possible – from the first to the last calibration – consequently allowing for full certification for regulatory compliance.

Additional advantages include the safe passage of the system through the oven, as well as a protection backup and the choice of a four- or six-channel system.

“R&C Instrumentation can send a product specialist to the client to do a site inspection, which will help the client to choose the correct system for its process,” he says.

The company also offers full training and aftersales support to clients on all of its temperature profiling solutions.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation