Firm’s industrial valves improve operationality, efficiency

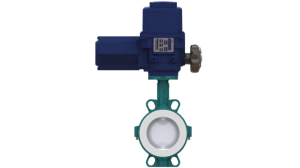

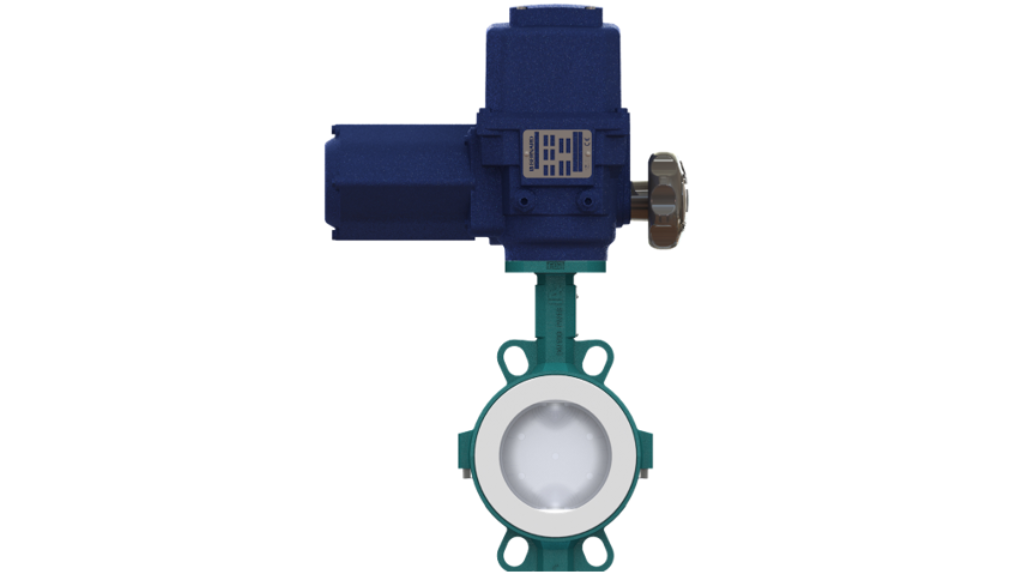

BIANCA BUTTERFLY VALVE BMG’s industrial valve solutions encompass a broad range of quality products, technical support and a dependable maintenance service for fluid control, gas regulation and high-pressure systems.

DESPONIA BUTTERFLY VALVE BMG’s Desponia range enhances water treatment processes by ensuring safe operations.

Industrial solutions provider BMG’s Fluid Technology division supplies and supports an extensive range of components for fluid technology systems and general industrial applications.

BMG’s strategy to enhance its fluid technology services to meet growing market demand encompasses the introduction of new products boasting the latest developments in design technologies, materials and coatings.

The company’s range of industrial valves meets stringent international quality standards, ensuring corrosion resistance, high-pressure endurance and long-term reliability – even in conditions with extreme temperatures and aggressive fluids.

Additionally, BMG’s extensive portfolio of quality branded valves meets diverse operational needs and includes ball valves designed for efficient shut-off control and smooth operation; gate valves that offer minimal pressure loss in high-pressure environments; and globe valves for precision flow regulation and throttling.

Meanwhile, its lightweight butterfly valves have been designed for quick adjustments, ensuring cost efficient operation, while check valves ensure backflow prevention and system integrity. BMG specialists also recommend the use of diaphragm valves for aggressive fluids and slurry handling as well as control valves for automating flow, pressure and temperature with ease.

BMG fluid technology division sales manager Susan Victor says that “no two industrial processes are alike, which is why technical advice from our experts is so important when selecting fluid control components”.

InterApp Bianca and Desponia Butterfly Valves

Key valves in BMG’s range include the InterApp Bianca and Desponia Butterfly Valves, says Victor.

Robust butterfly valves are designed for dependable shut-off and control of corrosive fluids, as well as high-purity applications. Compact butterfly valves, with good flow characteristics and low maintenance requirements, are “extremely versatile” and help to ensure dependable operation.

“The discs of butterfly valves are always present in the passageway within the flow, meaning that a pressure drop is induced in the flow regardless of the valve’s position.” Consequently, butterfly valves can be safely used for isolation and control of flow.

An advantage of using quarter-turn butterfly valves, rather than any other valve, is the wafer-shaped design, which enables easy repair and minimal maintenance.

BMG’s InterApp Bianca centric butterfly valves, with durable polytetrafluoroethylene (PTFE) liners, are built for long service life and suitable for aggressive and corrosive fluids.

These high-performance valves, available in sizes between DN 32 and DN 900, are manufactured with a ductile iron, carbon steel or stainless steel. These valves can be “configured” for specific applications.

For example, the US Food and Drug Administration-compliant Bianca valves (DN 50 to DN 200) with mirror-polished stainless-steel discs and high-purity PTFE liners, ensure the safe production of active pharmaceutical ingredients. Further, Bianca valves with perfluoroalkoxy- (PFA-) coated discs and PTFE liners can be used in highly corrosive, chemical applications.

Notable features of the Bianca series include a high liner collar, a PFA disc over-moulding on the shaft, as well as a lifetime pre-loaded safety shaft sealing, ensuring reliable primary and long-lasting secondary shaft sealing, even in demanding operating cycles and at high temperatures.

The chambered liner prevents cold flow at the flange sealing surface for increased service life and the PTFE liner, in combination with the PFA-over-moulded disc, ensures low friction, extending the life of the system.

Other features include an external shaft sealing mechanism to protect the valve neck hole and a self-lubricating, maintenance-free bushing. A stainless-steel valve label enables full traceability.

Typical applications for Bianca butterfly valves are in mining and slurries for the extraction of acids and solvents; for the processing of additives in the oil and gas sector; and for highly corrosive processes in the steel industry. This series is also suitable for use in water treatment applications.

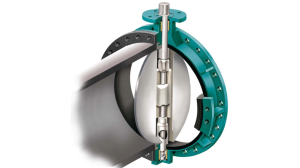

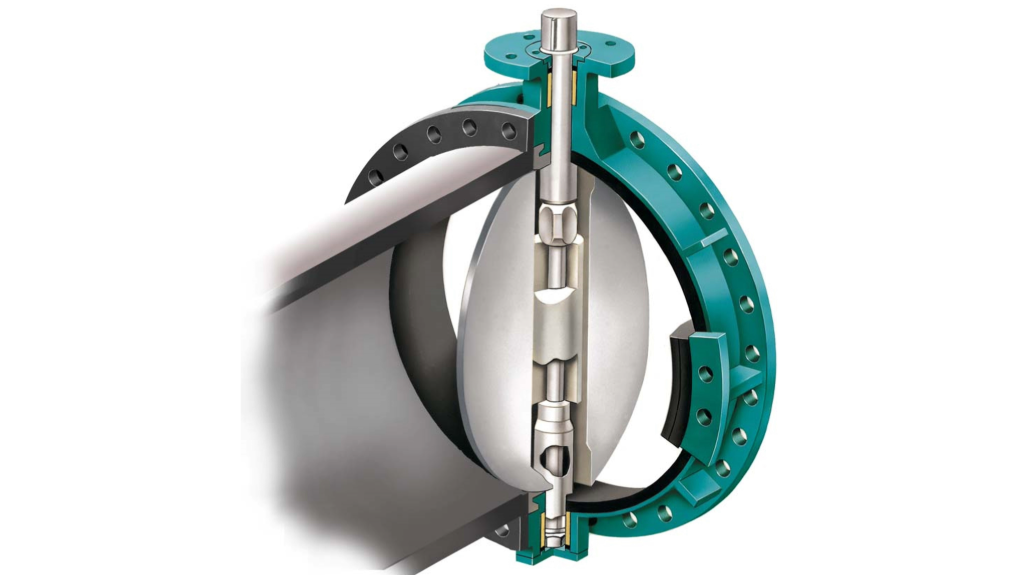

Meanwhile, BMG’s multi-purpose InterApp Desponia and Desponia Plus centric butterfly valves, with tough bodies and robust elastomer liners, are designed for safe and reliable regulation of liquids and gases in diverse sectors.

Desponia valves, which are available in sizes from DN 25 to DN 1 600 and pressures up to 16 bar, are suitable for numerous industrial applications. This range is available in cast iron and ductile iron.

The Desponia Plus range comes in sizes between DN 25 and DN 600, with high-pressure applications up to 20 bar, and is suitable for high-temperature or vacuum applications, as well as process automation. It is also available in ductile iron and cast iron as well as stainless steel.

Important features of the range include an external shaft sealing mechanism which protects the valve neck hole and a long neck design that enables pipe insulation. A retaining washer offers blow-out protection and the O-rings built in the shaft passage form part of the shaft sealing system. Sealing lips on the flange face offer “perfect tightness” and the optimised liner shape ensures a precise grip. The square-driven disc provides effective and durable torque transmission and the polished disc edges minimise friction.

The Desponia range ensures safe operation in water treatment processes and power generation and chemical processing applications. These valves can also withstand operation in the steel industry.

Moreover, BMG’s Fluid Technology services cover project engineering and consulting, cylinder design and manufacture, training, repair and testing, as well as on-site container services. BMG also offers total process and lubrication management solutions throughout Africa.

Trends such as smart valve automation, remote monitoring and predictive maintenance are considered, with BMG “constantly” modernising its valves offering to optimise efficiency, reduce downtime and lower operational costs.

“Our service is enhanced by an extensive supply chain and service network to ensure critical valve components are easily accessible,” Victor concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation