Pumps manufacturer proves its mettle at expo

A LITTLE XTRA The new MDX range of pumps has founded on three generations of success

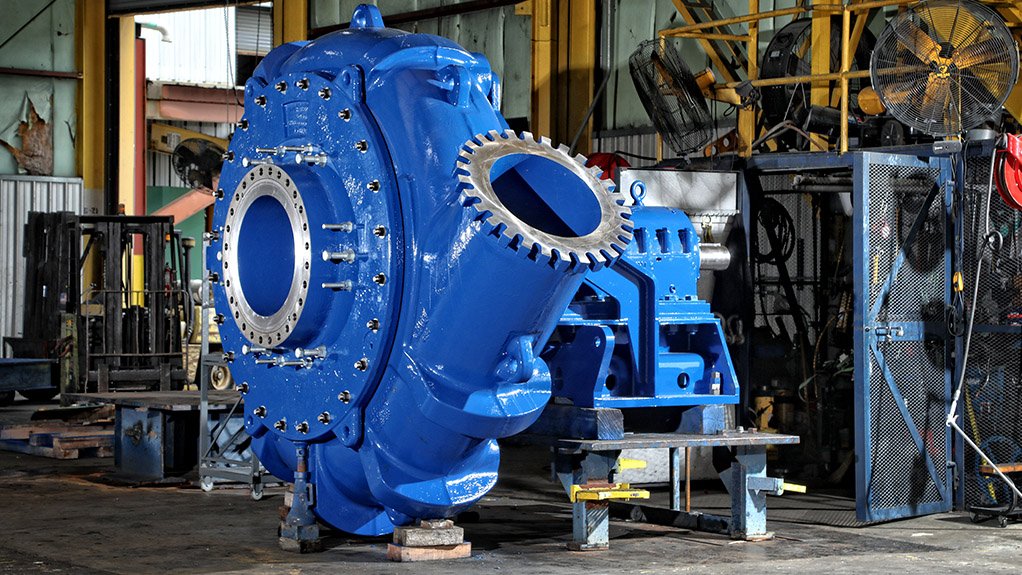

Multinational pumps manufacturer KSB Pumps and Valves showcased its third-generation Mill Duty Xtra (MDX) heavy pumps to the African market at this year’s Electra Mining Africa 2022 expo.

The MDX pump, referred to as “the heart of the mill circuit”, tackles the most extreme conditions, maximising productivity and minimising cost by matching operating cycle times with scheduled mill outages, says KSB Pumps and Valves mining sales manager Rob Bond.

The MDX’s slurry diverter significantly increases suction liner life by reducing particle recirculation between the impeller and liner, while the adjustable suction liner ensures extended suction liner wear.

“The third-generation MDX Slurry Diverter boasts design features that allow for optimal operation and reduces wear in the application in which it is used.”

Bond explains these design features include lower specific speed design, in which the large-diameter impeller results in slower pump operation, leading to extended wear life for parts.

The MDX range is fitted with KSB’s patented inlet 5 V impeller, which has been designed to handle liquid and solid phases within the slurry to maximise pump performance.

Additionally, the lower speed enables the pump operations to meet the variable flow conditions of modern mill circuits.

Materials with extended wear life and thicker cross sections are used in the pump’s construction, resulting in a longer and more reliable pump service life.

“Deep Base Circle technology minimises aggressive particle impingement, providing a ‘sliding’ wear action, which drops typical abrasive wear dramatically,” he adds.

The range’s oversized shrouds enhance its vane performance and provide added clearing action, which also minimises recirculation and wear between the impeller and suction liner.

The MDX pumps have been well received by companies in Chile, Indonesia, Canada, Brazil and Panama.

Meanwhile, KSB Pumps & Valves demonstrated its local manufacturing capabilities at the mining market area during this year’s Electra Mining expo, says Bond.

He cites, for example, the company’s remote adjusting mechanical suction liner (RAMSL), which was specifically designed for the MDX Pumps using real-time critical data and user interface output data such as vibration readings and precise movements of the suction liner.

The RAMSL is used in the mining sector on mill discharge pumps to automatically adjust the suction liner to reduce recirculation and increase the wear life of the suction liner.

The benefits of an RAMSL include a reduction in maintenance downtime and improved safety, as the suction liner need not be manually adjusted.

Bond concludes that Electra Mining was also used to promote brand awareness for the company, as well as network with new and existing clients.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation