Specialised welding enhances refurbishment capabilities

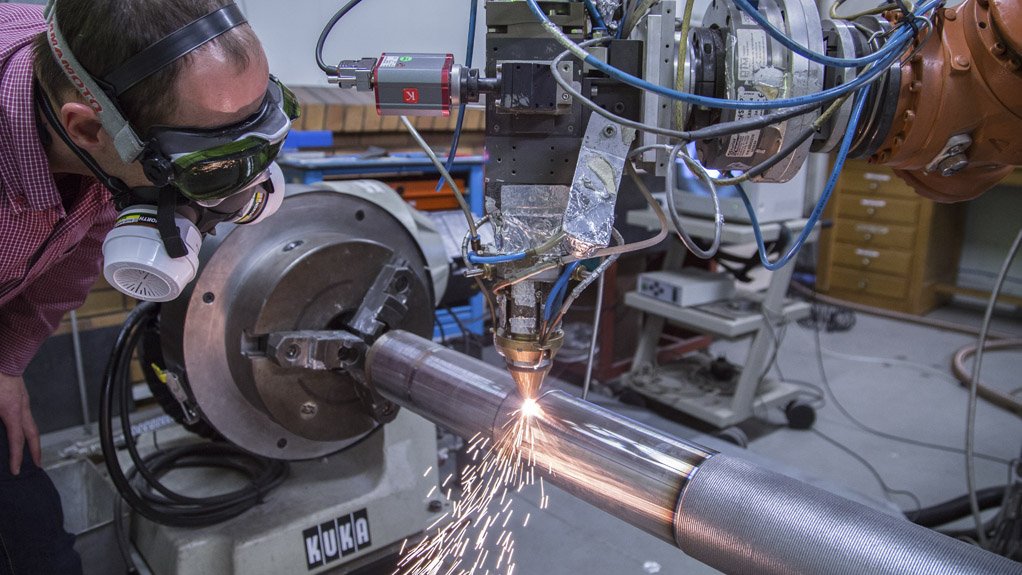

PRECISION WORK Laser welding is best used in combination with other welding processes for applications that require the highly specialised capabilities

Having proven the benefits of laser beam welding for the refurbishment of industrial components in a range of experimental projects, the Council of Scientific and Industrial Research’s (CSIR’s) National Laser Centre (NLC) is working to commercialise this specialised technique for the South African industrial sector.

“The CSIR has been focused on developing the capabilities of laser beam welding since 2004 and has started the process to commercialise the technology for the wider market. The CSIR is also engaging on a wider basis with industry in order to alert industrial companies of the benefits this technology offers,” says CSIR welding engineer Corney van Rooyen.

“We are confident that a strong market demand will follow the commercialisation of the technology and we are looking forward to securing a pipeline of projects that can benefit from the successes we have achieved to date.”

He explains that the laser welding process is similar to arc welding, but highlights that it uses a high-intensity infrared laser beam rather than an electric arc to heat the substrate of a component. It is a noncontact process that results in a metallurgical bond between the component and the deposited layer, rather than mechanical bonds. Laser beam welding has a lower energy input, compared with other welding processes. It also has a low dilution profile, which means that a thin layer of stainless steel (or any other metal alloy) can be deposited onto a component’s substrate, without the risk of distortion.

The laser beams are robotically manipulated and the power output can be controlled instantly, giving the process a very high level of control and accuracy when working with irregular shaped components.

However, Van Rooyen warns that laser welding will not replace conventional welding processes but should be regarded as a complementary technology. Laser metal deposition has a relative low deposition rate, which means that a smaller amount of metal is deposited on the substrate during the time that other processes can deposit much more.

If a significant amount of weld metal needs to be added to the component, another welding process – such as arc or plasma welding – is, thus, more appropriate in terms of efficiency and cost.

“Laser welding is best used in combination with other welding processes for applications that require the highly specialised capabilities it can provide to ensure the highest value- add is achieved when working to repair or enhance industrial components.”

A key part of the technology’s advancement has been driven by the CSIR’s partnership with State-owned power utility Eskom. The CSIR and Eskom tested the process in the refurbishment of PTR water storage tanks at Koeberg power station, in the Western Cape. The process, tested in 2011, proved successful in limiting the effects of stress corrosion crack- ing in the tanks and extended their service life by at least five years.

With this initial success, Van Rooyen notes that the opportunities for projects with the power utility “snowballed”, with laser welding subsequently employed in the refurbishment of turbine rotors, turbine blades and valves. A landmark project completed in May involved using laser technology to refurbish tenons, or rivets, on turbine rotor blade tips, used in the steam turbines of Eskom’s power plants.

The drive to commercialisation has further been supported by the CSIR’s partnership with industrial equipment supplier MAN Diesel & Turbo, which gained traction in 2012 when the NLC introduced its mobile laser welding system.

“Together, we have worked to expand the applications of laser welding and iron out any problems with the process. It has proven to be a very positive partnership and we are confident that it will continue to grow as we look to target the turbo machinery market, in particular,” concludes Van Rooyen.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation