Specialist manufacturer to provide fasteners for International Space Station

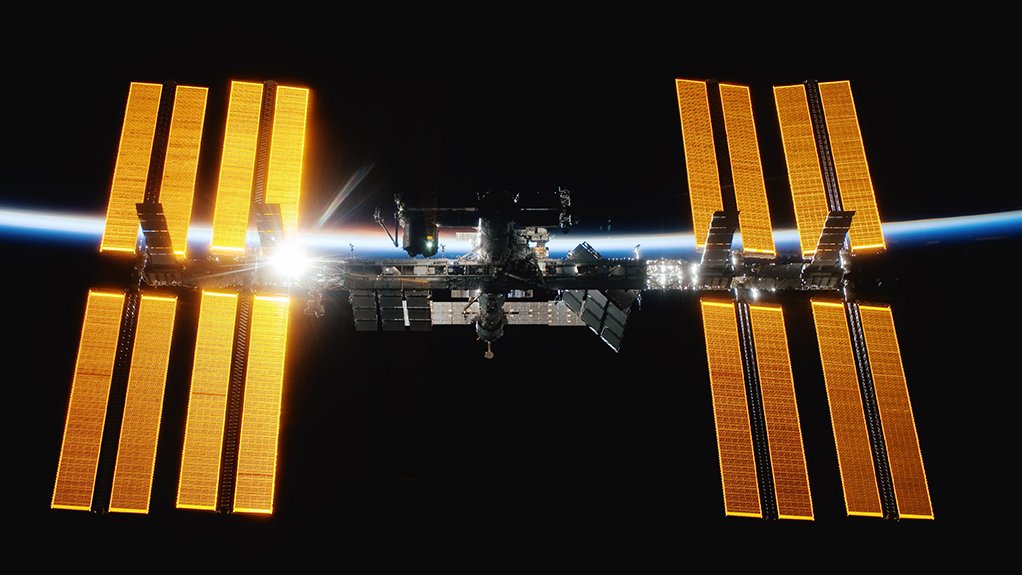

INTERNATIONAL SPACE STATION The ISS orbits the Earth at an altitude of 400 km and a speed of 28 000 km/h, which means it orbits the Earth every 90 minutes

Specialist fastener manufacturer Bumax has been selected to provide crucial fasteners to be used on the International Space Station (ISS). BUMAX 88 fasteners will be used to secure a new payload going to the ISS to measure the speed of sound.

BUMAX premium fasteners include some of the strongest in the world, the company says, adding that they are being used in a variety of “extremely demanding and cutting-edge scientific applications”, such as at scientific research institute CERN in Switzerland and for the world’s largest optical telescope in northern Chile.

The space sector continues to benefit from the BUMAX fastener range with various applications. BUMAX extra strong and fatigue resistant model 88 has been selected to securely fasten the housing of a new payload on the ISS called Granular Sound.

The customer is European space and technology group OHB SE subsidiary OHB System AG, under contract of the European Space Agency (ESA).

Granular Sound is an experiment in space to measure the speed of sound through a cube filled with glass balls (a so-called package) in microgravity at different package pressures. The experiment uses thousands of glass balls to simulate granular media like sand or concrete.

“The housing of this package will be securely fastened by BUMAX 88 fasteners to avoid the balls from flying around the ISS,” says OHB Systems AG project manager and systems engineer Lukas Pfeiffer, who adds that “the microgravity experiment will provide valuable data for various terrestrial and space applications – from more effective concrete processing to three-dimensional printing in space or on the moon”.

The enhanced properties of BUMAX 88 fasteners are achieved through a combination of unique BUMAX manufacturing processes and the highest quality European steel.

Monitoring Air Quality

Since January 2022, BUMAX 88 screws have also been used for the ANITA-2 trace gas monitoring system to ensure good air quality for the ISS astronauts. The system, developed by OHB System AG, has been simultaneously measuring more than 40 gases every six minutes on the ISS, the company says.

BUMAX 88 screws were used for the ANITA-2 payload to securely seal a safety containment and fasten crucial optical components.

“Being trusted with supplying fasteners for projects such as CERN and ISS, which are essential to the evolution of mankind, is of course a source of immense pride and a testament to the quality of our products and BUMAX as a whole,” comments Bumax MD Lars Holm.

He adds that being repeatedly chosen for the most demanding applications means that all its existing and new customers can “rest assured that they are getting the best of the best”.

The ISS was launched in 1998 to gain more knowledge about space and is crewed by up to seven people.

The ISS orbits the Earth at an altitude of 400 km and a speed of 28 000 km/h, which means it orbits the Earth every 90 minutes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation